Lactobacillus plantarum and its application

A technology of Lactobacillus plantarum and strains, applied in the direction of Lactobacillus, application, bacteria, etc., can solve the problems of slow growth of lactic acid bacteria and low quality of alfalfa silage, and achieve the effects of accelerating the fermentation process, increasing in vitro digestibility, and improving the quality of silage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

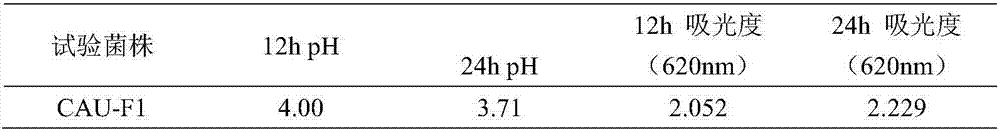

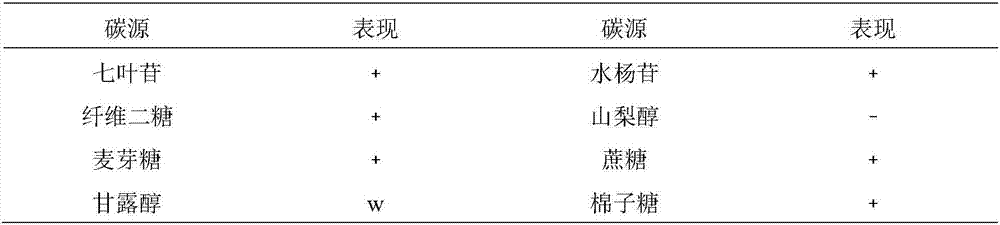

[0036] Example 1: Isolation and strain identification of Lactobacillus plantarum CAU-F1

[0037] 1. Isolation of strains

[0038] Separation of Lactobacillus plantarum by dilution plate method: Weigh 0.5g of feces samples from Holstein middle-period dairy cows, place them in a test tube filled with 4.5mL sterilized physiological saline, shake them well to make them evenly mixed, and the dilution of this test tube is 10 -1 , and then pipette 0.5mL to the next test tube, and dilute the samples to 10 -6 , then draw 0.1mL of the diluted sample and spread it on the MRS medium plate, place it in an anaerobic incubator at 30°C for 48 hours, pick colonies with different shapes and colors on a plate with a suitable colony density, and continue to streak Cultivate until the colony is monotonous, pick a typical colony, and carry out catalase activity determination, Gram staining and microscopic examination. Any strains that are Gram-positive and catalase-negative can be preliminarily i...

Embodiment 2

[0069] Embodiment 2: the preparation of alfalfa silage

[0070] The preparation of alfalfa silage comprises the following steps:

[0071] (1) Dry the alfalfa to a moisture content of about 60%, cut it to 1cm-2cm, and mix well;

[0072] (2) To step (1) alfalfa according to 6log cfu g -1 Lactobacillus plantarum (Lactobacillus plantarum) CAU-F1 was inoculated, and no addition (Control), GFG (commercial bacterial agent), FG1 (commercial bacterial agent) were used as controls, and each treatment was repeated 3 times;

[0073] (3) Put the alfalfa from step (2) into 30cm×20cm polyethylene silage bags, 100g in each bag, pump air with a vacuum sealing machine, seal it, and store it at room temperature for 60 days.

[0074] Nutritional quality, fermentation quality, microbial analysis and in vitro digestion experiments were carried out after alfalfa silage.

[0075] 1. Determination of nutritional quality and fermentation quality of silage:

[0076] After silage, weigh 10g of a repr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com