Hydrogel with multiple response function and preparation method and application thereof

A multi-response, hydrogel technology, applied in the field of biomedical materials, to achieve excellent mechanical properties, biocompatibility, and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

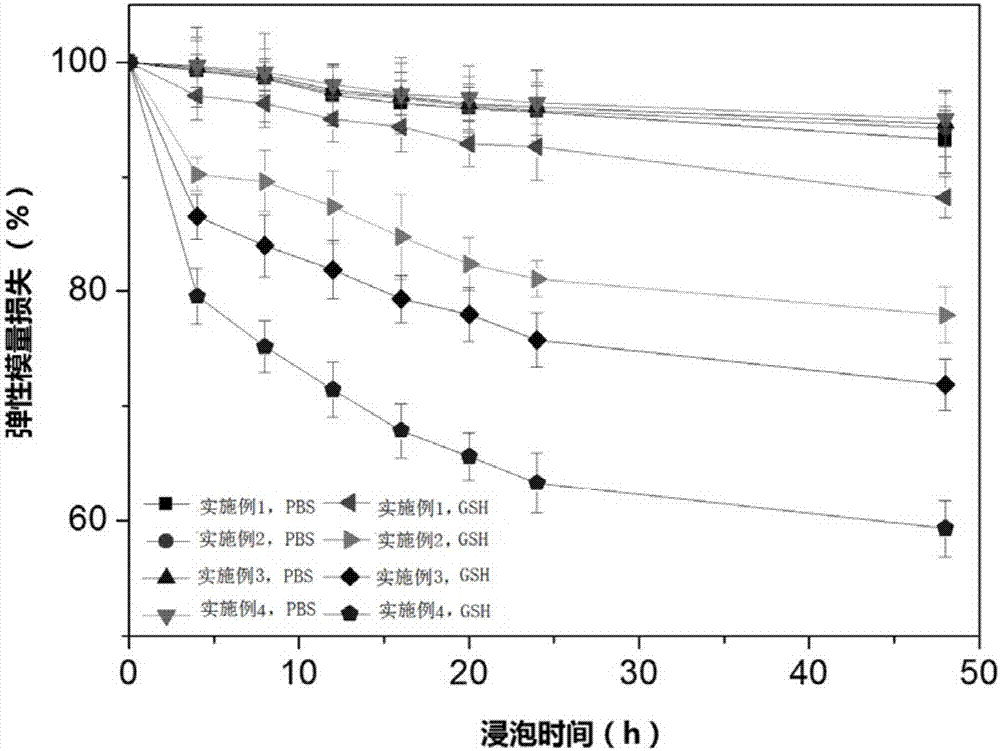

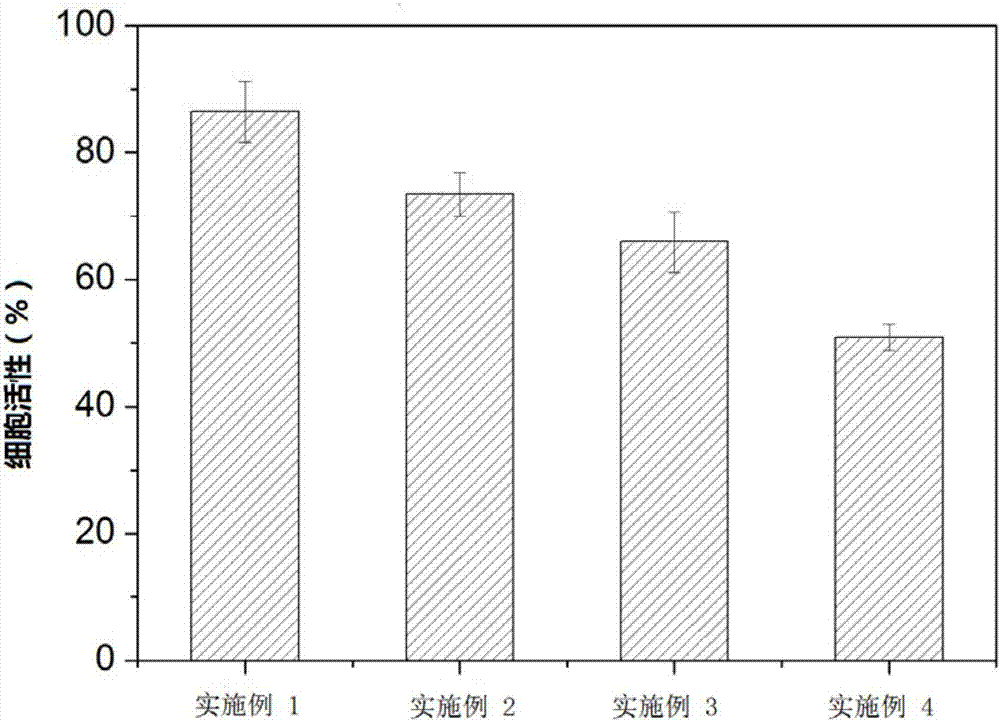

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation of hydrogel material comprises the following steps:

[0048] (1) Preparation of modified hydrogel material: 12.6g of Pluronic F-127 was dissolved in 100mL of a mixed solution with a volume ratio of dichloromethane: acetone = 1:1, and 3mL of acryloyl chloride and 3mL of Tris were added dropwise in an ice bath. Ethylamine, react in ice bath for 12h, and react at room temperature for 12h. After the reaction, washed with saturated sodium bicarbonate solution, rotary evaporated and vacuum dried at 40° C. for 24 hours to obtain modified F-127 (12 g).

[0049] (2) Preparation of modified double selenium: After synthesizing the double selenide product according to the literature, get 1g of double selenide and dissolve it in 50mL dichloromethane solution, feed nitrogen gas into the reaction system for half an hour, then ice bath 6 mL of acryloyl chloride and 7 mL of triethylamine were added dropwise, reacted in ice bath for 3 h, and reacted at room temperature f...

Embodiment 2

[0052] Preparation of hydrogel materials

[0053] In the step (3) of Example 1, "the modified di-selenide material of 10g and the photopolymerization initiator of 10g are dissolved in the vinylpyrrolidone solution of 100mL" to be changed into "the modified di-selenide material of 20g and the photopolymerization initiator of 10g Photopolymerization initiator is dissolved in the vinylpyrrolidone solution of 100mL", all the other are identical with embodiment 1. At this point in the final mixed solution, the mass ratio of the modified di-selenium material to the modified F-127 is 1:10.

Embodiment 3

[0055] Preparation of hydrogel materials

[0056] In the step (3) of Example 1, "the modified di-selenide material of 10g and the photopolymerization initiator of 10g are dissolved in the vinylpyrrolidone solution of 100mL" to be changed into "the modified di-selenium material of 30g and the photopolymerization initiator of 10g Photopolymerization initiator is dissolved in the vinylpyrrolidone solution of 100mL", all the other are identical with embodiment 1. At this point in the final mixed solution, the mass ratio of the modified di-selenium material to the modified F-127 is 3:20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com