Method and device for separate treatment of alkali weight reduction wastewater

A technology for alkali reduction wastewater treatment and quality separation, which is applied in textile industry wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. The problems of rising costs and difficulty in stably reaching the standard of effluent can achieve the effects of reducing the amount of odorous gas generated, reducing the hydraulic retention time, and reducing the salt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

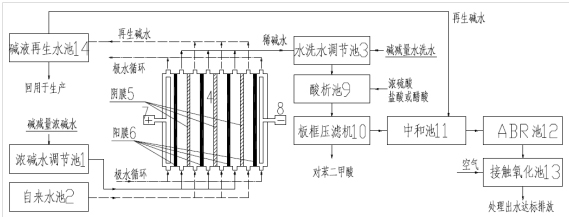

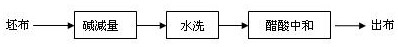

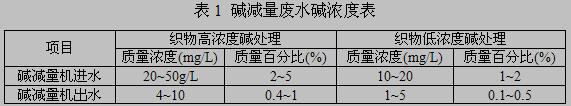

[0035] The alkali reduction wastewater treatment method of the present invention is a new method that combines reverse osmosis and biological treatment. By diverting the alkali reduction wastewater in different stages, the concentrated water reverse osmosis dilutes the salt to reduce the harm to the biological system, and the regenerated alkali solution is reused. , dilute alkaline water and alkali-reduced washing water are mixed and then biologically treated to achieve the purpose of recycling useful resources and purifying them. In the present invention, the initial alkali reduction wastewater is the alkali reduction concentrated alkaline water, and the subsequent washing and acetic acid neutralization wastewater are collectively referred to as alkali reduction washing water.

[0036] like figure 1 As shown, an alkali reduction waste water qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com