A method for preparing titanium-silicon molecular sieve ts-1 with high skeleton titanium content

A titanium-silicon molecular sieve, TS-1 technology, applied in the direction of molecular sieve compounds, molecular sieve characteristic silicates, molecular sieves and alkali-exchange compounds, etc., can solve the problems of low content of framework titanium and unavoidable non-framework titanium, and reduce the synthesis cost , reduce cost input, and stabilize the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Add 20.3g of methyl orthosilicate into a jacketed three-necked flask, sequentially add 0.78g of tetraethyl titanate and 42.1g of 25wt% tetrapropylammonium hydroxide solution, immerse the three-necked flask in a 40°C water bath, and hydrolyze for 1.5 h. The hydrolyzate was dealcoholized at 90°C for 1 hour, 180mL of starch solution with a concentration of 5wt% was added, stirred evenly, the mixed solution was put into a crystallization kettle, and crystallized at 160°C for 48h, the crystallized product was washed and dried, Calcined at 540°C for 6 hours to obtain TS-1, which is numbered TS-1-E.

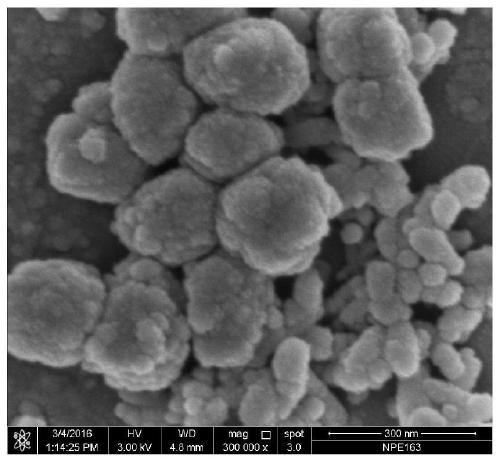

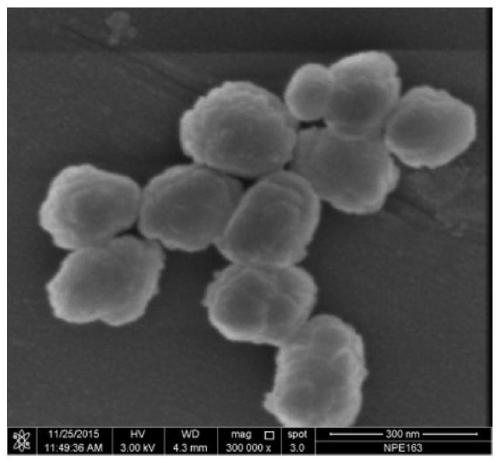

[0051] image 3 It is the scanning electron micrograph of the titanium-silicon molecular sieve TS-1-E that embodiment 1 makes, as can be seen from the figure, the morphology of the sample that the present embodiment makes and figure 1 Very similar, ellipsoidal, particle size is about 200nm.

[0052] Depend on Figure 5 It can be seen that the sample TS-1-E synthesized accordi...

Embodiment 2

[0055] Add 29.6g of ethyl orthosilicate into a jacketed three-necked flask, sequentially add 1.60g of tetrabutyl titanate and 33.6g of 25wt% tetrapropylammonium hydroxide solution, immerse the three-necked flask in a 50°C water bath, and hydrolyze for 3 hours . The hydrolyzate was dealcoholized at 90°C for 1 hour, 100mL of starch solution with a concentration of 5wt% was added, stirred evenly, the mixed solution was put into a crystallization kettle, and crystallized at 170°C for 60h, the crystallized product was washed and dried, Calcined at 540°C for 5 hours to obtain TS-1, which is numbered TS-1-F.

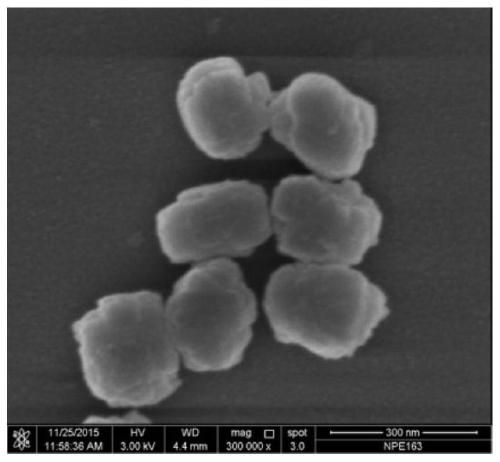

[0056] Figure 4 It is the scanning electron micrograph of the titanium-silicon molecular sieve TS-1-F that embodiment 2 makes, as can be seen from the figure, the morphology of the sample that the present embodiment makes and figure 1 Very similar, ellipsoidal, particle size is about 200nm.

[0057] Depend on Figure 5 It can be seen that the sample TS-1-F synthesized acco...

Embodiment 3

[0060] Add 20.8 g of ethyl orthosilicate into a jacketed three-necked flask, sequentially add 0.96 g of tetrabutyl titanate and 9.8 g of 40 wt % tetraethylammonium hydroxide solution, immerse the three-necked flask in a 50° C. water bath, and hydrolyze for 1 h. The hydrolyzate was dealcoholized at 90°C for 0.5h, and 90mL of starch solution with a concentration of 8wt% was added, stirred evenly, and the mixed solution was put into a crystallization kettle, and crystallized at 150°C for 72h, and the crystallized product was washed and dried. Calcined at 540°C for 3 hours to obtain TS-1, which is numbered TS-1-G.

[0061] Depend on Figure 5 It can be seen that the sample TS-1-G synthesized according to Example 3 only contains framework titanium, and does not contain hexacoordinated non-framework titanium and anatase TiO 2 .

[0062] Depend on Figure 6 It can be seen that the TS-1-G synthesized according to Example 1 also has a typical MFI structure, and the crystallinity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com