A kind of preparation method of high-purity spherical magnesium carbonate powder for cosmetics

A technology of magnesium carbonate and cosmetics, applied in the direction of magnesium carbonate, etc., can solve the problems of short reaction time, excessive heavy metal ion concentration, unsatisfactory, etc., achieve low production cost, reduce waste liquid treatment cost, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

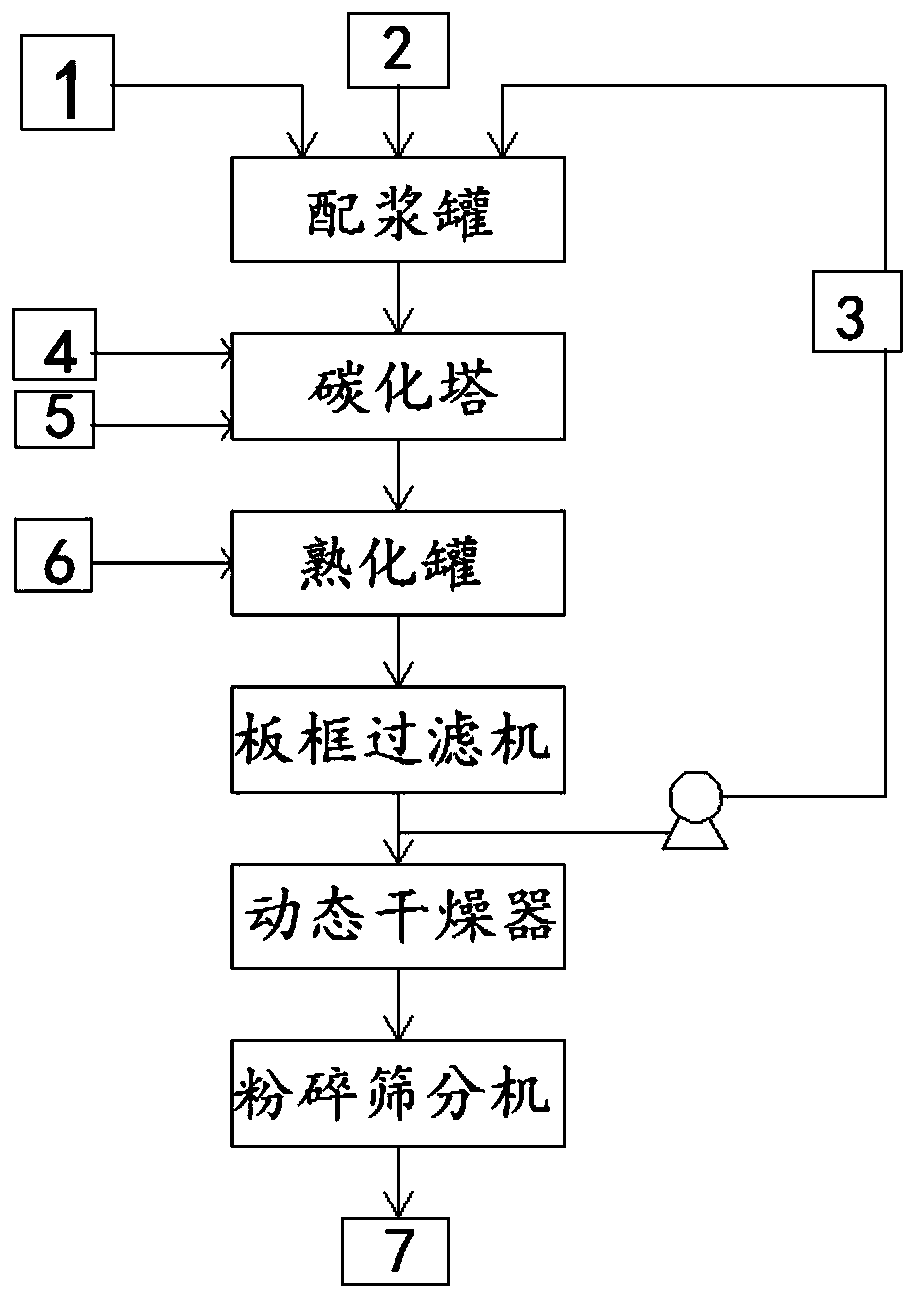

Method used

Image

Examples

Embodiment 1

[0043] The average particle diameter of the selected raw material magnesium hydroxide (1) is 180nm, the heavy metal content calculated as lead is 8ppm, and the chloride ion content is 0.015%. Weigh 180 kg of the raw material magnesium hydroxide (1) into the slurry mixing tank, add deionized water (2) to prepare magnesium hydroxide reaction slurry A with a mass concentration of 60 g / L.

[0044] Put the reaction slurry A in the mixing tank into the carbonization tower, and add the carbonized crystal form directing agent (5) into the carbonization tower, the added carbonized crystal form directing agent is sorbitol, and the concentration of sorbitol in the carbonization tower 0.5g / L; Then feed pressure and be 0.2MPa carbon dioxide (4) to carry out carbonization reaction, control carbonization reaction temperature to be 30 ℃, when the pH of the slurry in the carbonization tower reaches 8.5, carbonization reaction is completed, obtains intermediate product magnesium carbonate slurry...

Embodiment 2

[0049] The average particle diameter of the selected raw material magnesium hydroxide (1) is 200nm, the heavy metal content calculated as lead is 10ppm, and the chloride ion content is 0.02%. Weigh 150 kg of the raw material magnesium hydroxide (1) into the slurry mixing tank, add deionized water (2) to prepare magnesium hydroxide reaction slurry A with a mass concentration of 50 g / L.

[0050] Put the reaction slurry A in the mixing tank into the carbonization tower, and add the carbonization crystal form directing agent (5) in the carbonization tower, the added carbonization crystal form directing agent is glycerol and lecithin, and in the carbonization tower, glycerol and The concentration of lecithin is respectively 0.4g / L; Pass into pressure then and be 0.4MPa carbon dioxide (4) to carry out carbonization reaction, control carbonization reaction temperature to be 50 ℃, when the pH of slurry in the carbonization tower reaches 9.0, carbonization reaction is completed, obtains...

Embodiment 3

[0055] The average particle diameter of the selected raw material magnesium hydroxide (1) is 140nm, the heavy metal content calculated as lead is 9ppm, and the chloride ion content is 0.01%. Weigh 210 kg of the raw material magnesium hydroxide (1) into the slurry mixing tank, add deionized water (2) to prepare magnesium hydroxide reaction slurry A with a mass concentration of 70 g / L.

[0056] Put the reaction slurry A in the mixing tank into the carbonization tower, and add the carbonization crystal form directing agent (5) into the carbonization tower, the added carbonization crystal form directing agent is glycerol, and the concentration of glycerin in the carbonization tower is 0.9 g / L; Then feed pressure and be 0.8MPa carbon dioxide (4) to carry out carbonization reaction, control carbonization reaction temperature to be 60 ℃, when the pH of slurry in the carbonization tower reaches 9.0, carbonization reaction is finished, obtains intermediate product magnesium carbonate sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com