Corynebacterium glutamicum for producing high-yield succinic acid by utilizing straw hydrolysate, and construction and applicaitons

A Corynebacterium glutamicum and succinic acid technology, applied in the direction of bacteria, microbial-based methods, and the use of vectors to introduce foreign genetic material, can solve the problems of no transformation of xylose metabolism ability and low production rate of succinic acid, and achieve good results. The effect of industrial potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: pD-sacB knockout vector construction and Corynebacterium glutamicum seamless knockout operation

[0035] (1) Construction of pD-sacB knockout vector

[0036] Firstly, the linear fragment of pK18mobsacB cut by HindIII was used as a template, and the primer sacB1 / sacB2 was used to amplify the sacB gene, which was about 1.6kb.

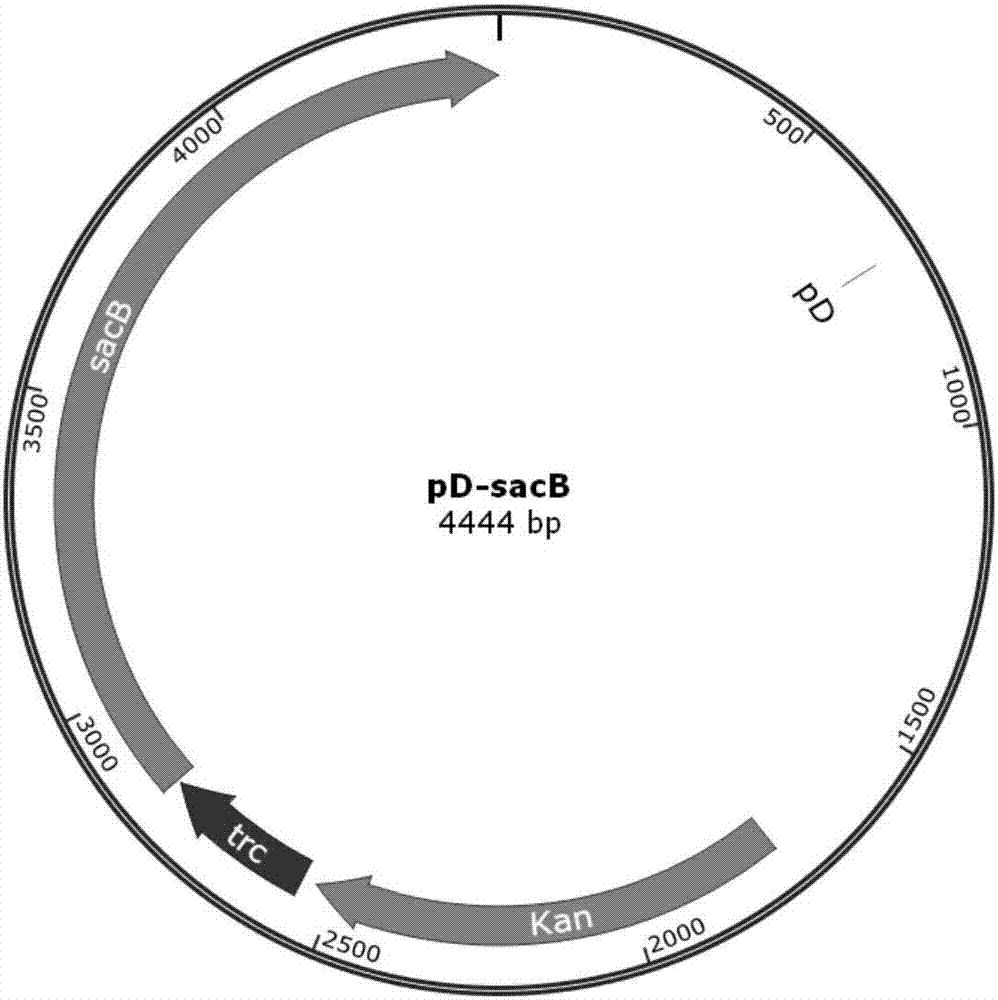

[0037] Connect the sacB gene digested by MunI / EcoRV to the pECXK99E digested by EcoRI / SmaI, and then use the following primers trcsacB1 / trcsacB2 to amplify the trcsacB fragment containing the trc promoter with the pECXK99E-sacB plasmid as a template, about 1.8 kb. Using primers pD1 / pD2, the pK18mobsacB plasmid was used as a template to amplify the pD fragment containing kanamycin resistance and E. coli replicon, about 2.6kb. Finally, the AatII digested fragment trcsacB and pD were ligated to obtain pD-sacB. The final pD-sacB plasmid map is as follows figure 1 shown.

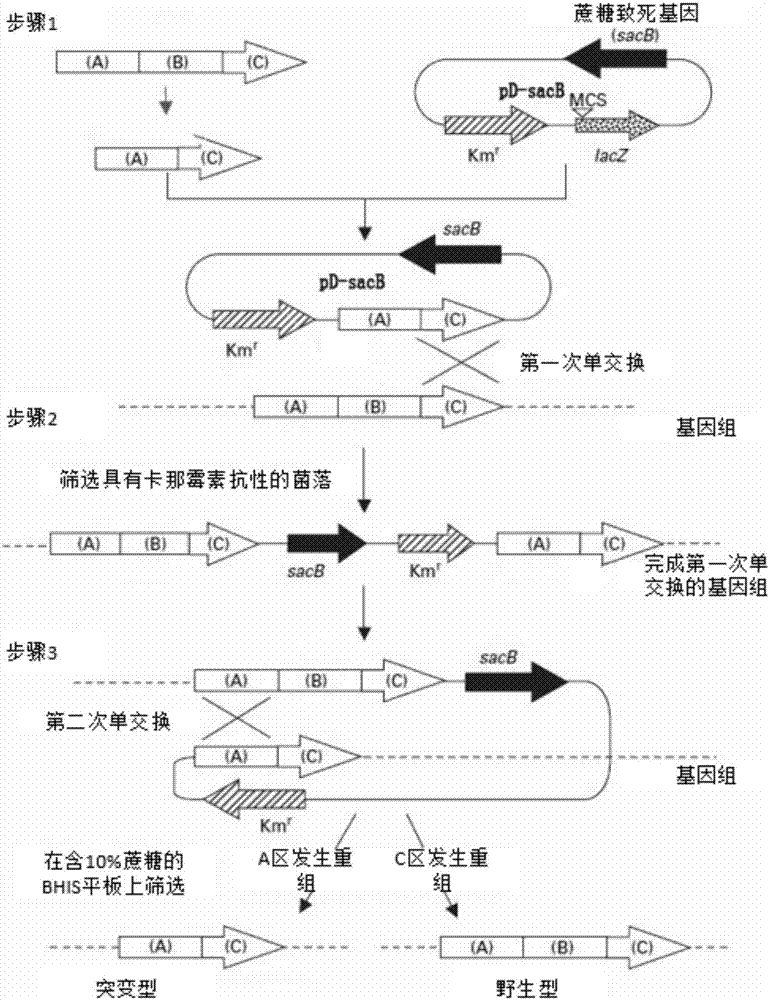

[0038] (2) Corynebacterium glutamicum traceless knockout operatio...

Embodiment 2

[0047] Example 2: Knockout of by-product acetic acid production pathway pta-ackA gene operon, by-product acetic acid production pathway actA gene and by-product lactic acid production pathway ldh gene

[0048] (1) The specific operation of knocking out the pta-ackA gene operon of the acetate production pathway is as follows:

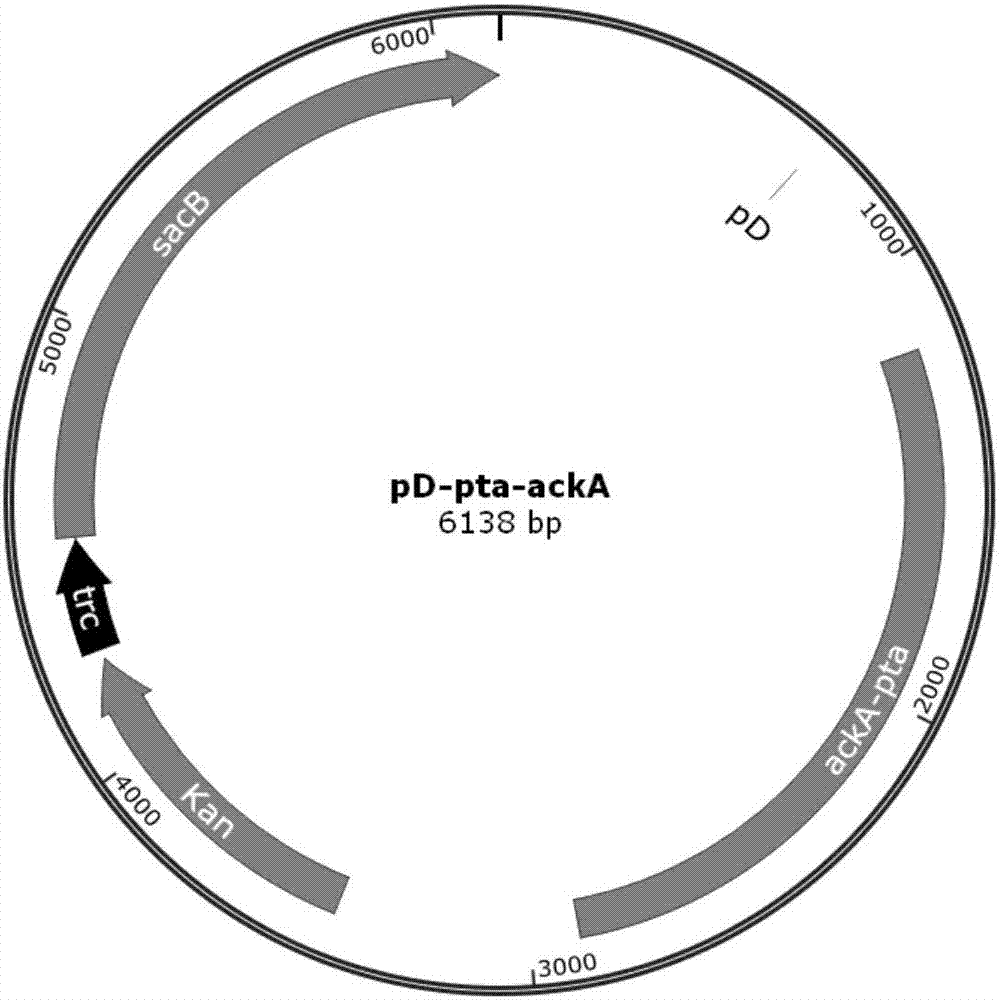

[0049] Using two pairs of primers pta1, pta2, pta3, pta4, and using C. glutamicum ATCC 13032 as a template, KOD-plus high-fidelity DNA polymerase was used to amplify the upstream and downstream homology arms with sizes of 870bp and 929bp, respectively. After gel cutting and recovery, primers pta5 and pta6 were used to perform fusion PCR amplification using KOD-plus high-fidelity DNA polymerase to obtain a splicing product of about 1.6 kb in the upstream and downstream homology arms. Then the fusion product and the pD-sacB plasmid were digested with Thermo Fast digestXbaI / SalI, and after ligation and transformation, the pta-ackA gene operon knockout vecto...

Embodiment 3

[0054] Example 3: Introduction of P before the start codon of the phosphoenolpyruvate carboxylase ppc gene on the chromosome sod Strong promoter, P sod Strong promoter (different from 001)

[0055] (1) On the chromosome, P sod The specific operation of the strong promoter is as follows:

[0056] Using the C. glutamicum ATCC 13032 genome as a template, PCR amplification was performed with the following primers. sodppc1 and sodppc2 were used to amplify the upstream fragment (557bp) of gene ppc. sodppc3 and sodppc4 are used to amplify the promoter of sod gene (192bp). sodppc5 and sodppc6 were used to amplify the initial fragment (563bp) of gene ppc. After the three fragments were gel-cut, purified and recovered, the equimolar proportion of the fragments was used as a template, and sodppc1 and sodppc6 were used as primers to amplify the fusion product (1.3 kb) of the three fragments. Then the fusion product and pD-sacB plasmid were digested with Thermo Fast digest XbaI / HindI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com