Anti-blocking segmented arrangement system for air pre-heaters

An air preheater and flue gas technology, applied in the field of boilers, can solve the problems of increasing the risk of low temperature corrosion of heat storage elements, air preheater corrosion and ash blocking, and increased ammonium hydrogen sulfate generation, etc. Improve and solve the problem of ash blocking and improve the effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

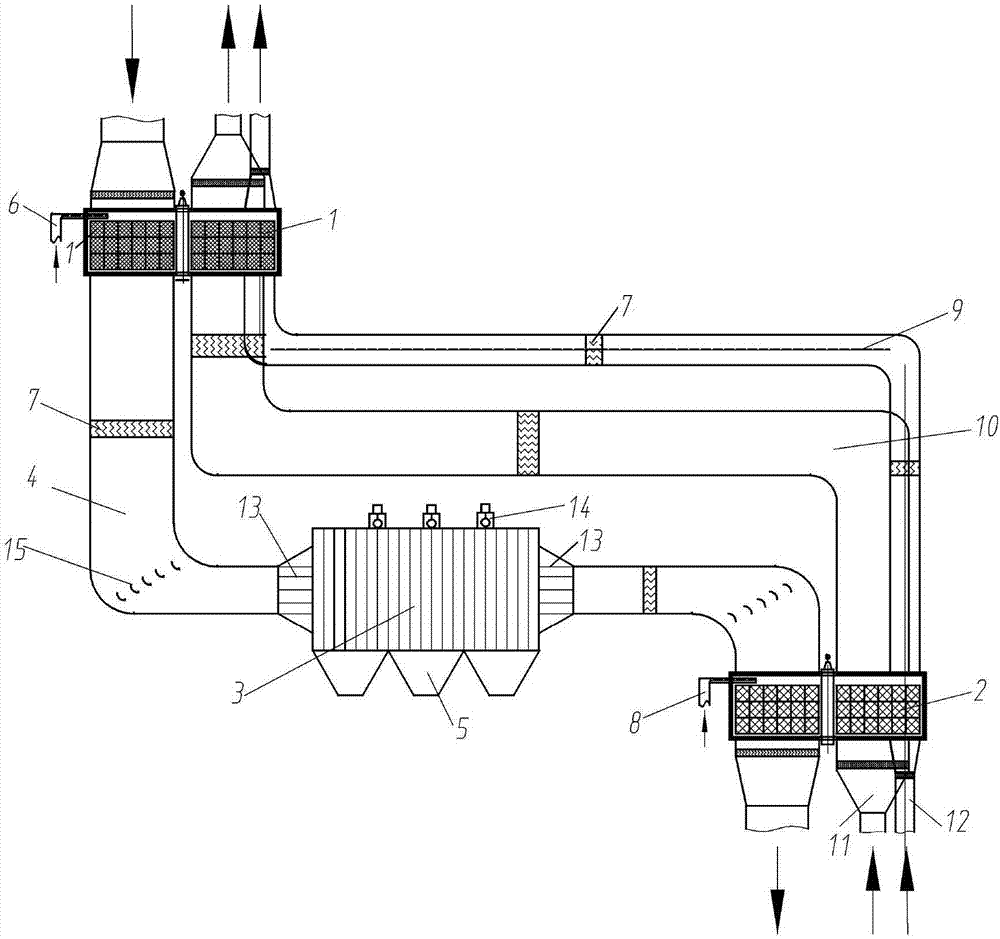

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] see figure 1 , the present invention proposes an anti-blocking type air preheater segmented arrangement system based on a different arrangement from the traditional air preheater. The purpose is to completely improve the working environment of the air preheater heat storage element without affecting the thermal efficiency of the boiler. , in order to deal with the common ash plugging problem in the air preheater after the SCR denitrification device is put into operation.

[0024] The system includes a high temperature air preheater 1, a high temperature electrostatic precipitator 3 and a low temperature air preheater 2. The low-temperature air preheater 2 is arranged in front of the low-temperature electric dust collector, and the high-temperature electric dust collector is arranged on the flue gas side between the high-temperature air preheater and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com