Novel sample dyeing machine

A dyeing machine, a new type of technology, applied in the field of small sample dyeing machines, can solve the problems of troublesome installation of cooling water pipes, environmental protection, waste of energy, etc., to achieve the effect of eliminating pipeline installation, saving energy and improving the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

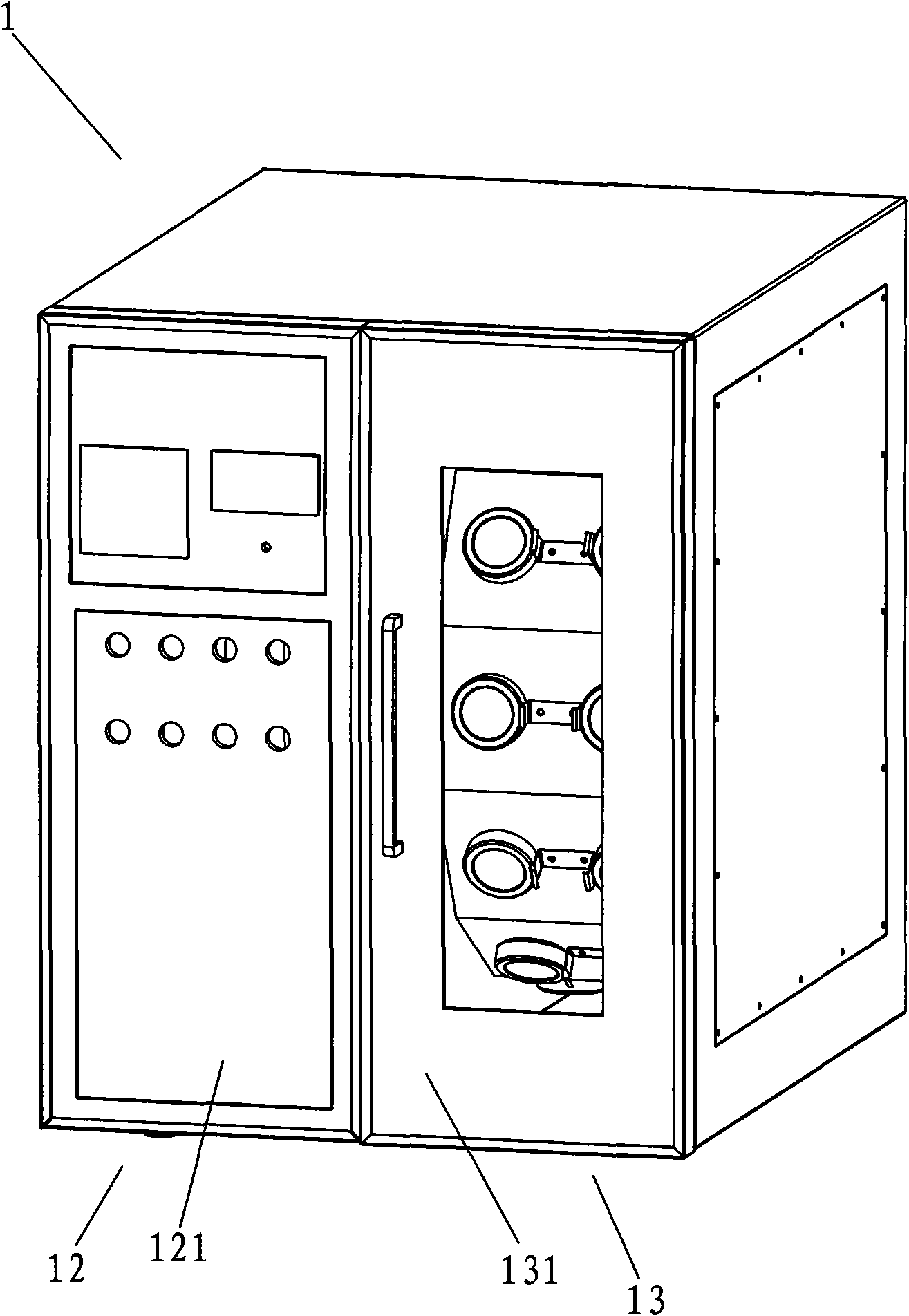

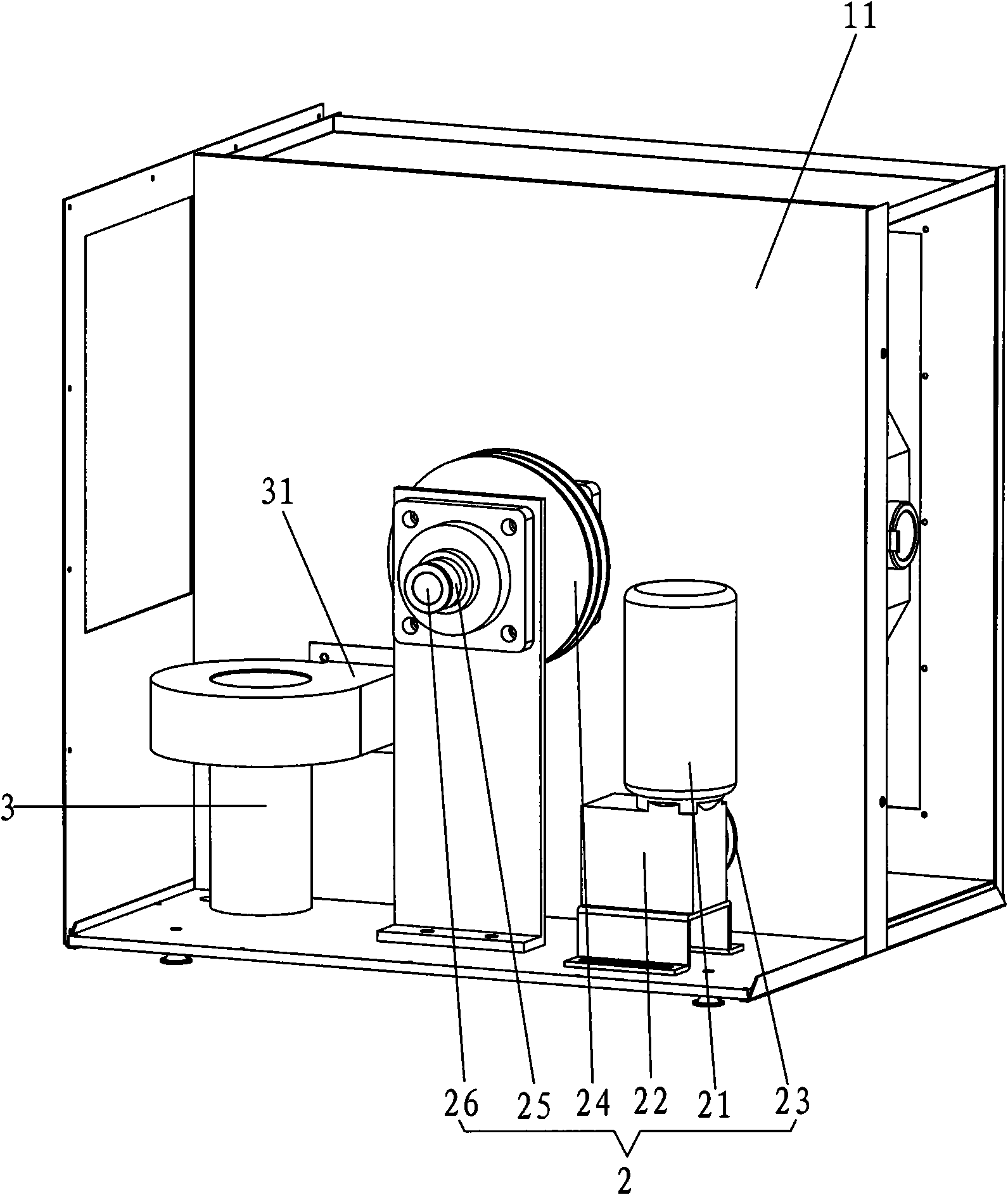

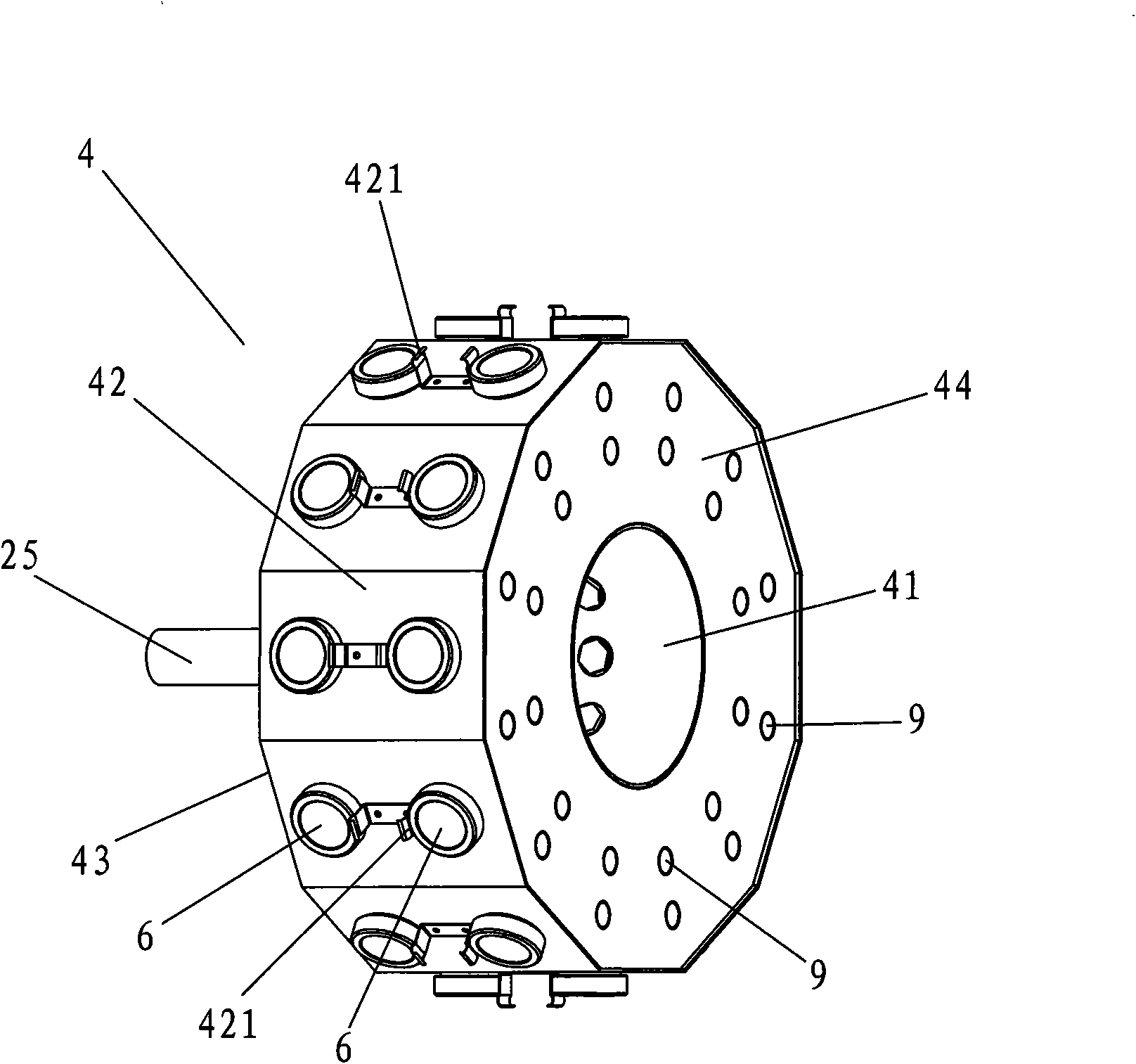

[0018] A kind of novel sample dyeing machine of the present invention, as figure 1 , 2 , 3, 4, and 5, the casing 1 is divided into a left casing 12 and a right casing 13 (cylinder body) by a partition 11, a transmission device 2, a blower fan 3, a temperature controller (not shown) and The control device (not shown) is arranged in the left housing 12, the control switch of the control device is arranged on the front panel 121 of the left housing 12, the swivel frame 4 is arranged in the right housing 13 (cylinder body), and the right The casing 13 is provided with a door 131 that can be opened movably.

[0019] The transmission device 2 includes a motor 21 , a reduction box 22 , a pulley 23 , a pulley 24 and a rotating shaft 25 which are sequentially connected by transmission. The extension end of the rotating shaft 25 is provided with an electric rotary joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com