High-temperature integrated down-hole temperature and pressure measurement system

A technology of downhole temperature and measurement system, applied in the field of detection and control system, temperature and pressure detection and control system, can solve the problems of low integration and intelligence, scattered circuit structure, poor reliability, etc., and achieve reasonable structural design. , Easy to use, flexible, accurate and accurate measurement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

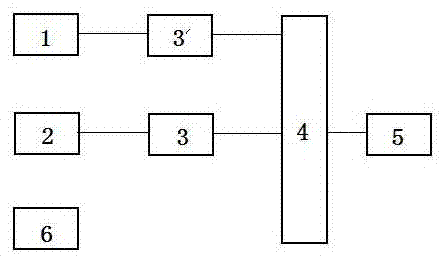

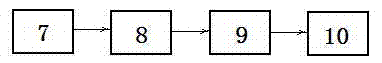

[0010] Depend on Figure 1-Figure 2 The high-temperature integrated downhole temperature and pressure measurement system of the present invention is composed of a high-temperature and high-precision pressure sensor 1 with sapphire as a sensitive element, a high-temperature measurement and control system, a data communication interface, and a programming port. A high-temperature integrated independent chip. The high-temperature measurement and control system is to send the sensing signals of the high-temperature high-precision temperature sensor and the pressure sensor 2, 1 (hereinafter referred to as the temperature sensor and the pressure sensor), that is, the analog voltage signal, to the amplification conditioning unit 3 and the amplification conditioning unit 3′ respectively. , filter, amplify, and compensate the analog voltage under the condition of temperature and pressure changes, and then connect it to the central processing unit 4. After the digital conversion is perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com