Water-based steel structure anticorrosion aqueous dispersion coating and preparation method and application thereof

A steel structure and dispersion technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as poor physical and chemical properties, limited construction conditions, and unsatisfactory service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

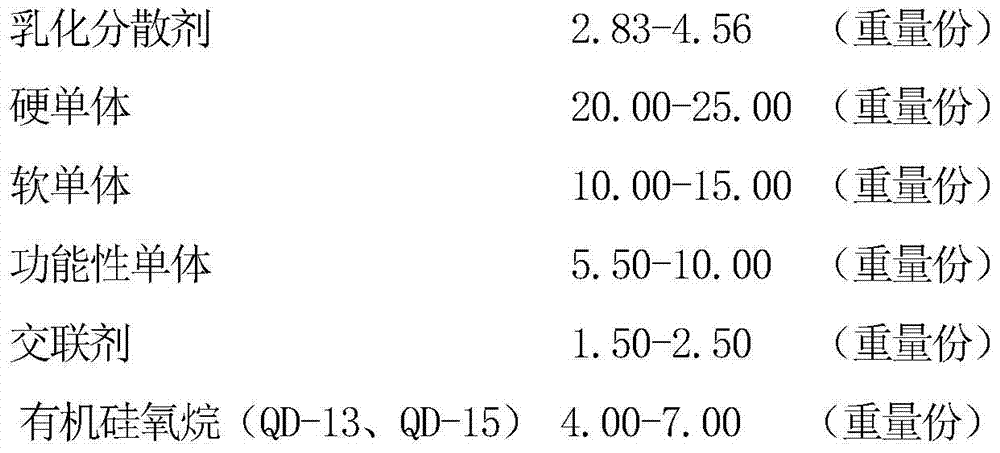

[0088] The preparation of embodiment 1 modified nano water dispersion polymer emulsion

[0089] 1. Raw material

[0090] Modified nano-microcrystalline kaolinite, provided by Zhejiang Fenghong Clay Co., Ltd.; xanthan gum, provided by Shanghai Liqi Chemical Auxiliary Co., Ltd.; citric acid, provided by Wujiang Weibo Chemical Technology Co., Ltd.; methyl methacrylate Ester, styrene, butyl acrylate, 2-ethylhexyl acrylate, acrylic acid, methacrylic acid, provided by Shanghai Acrylic Chemical Co., Ltd.; phosphate methacrylate, TM-200 double bond-containing dicarboxylic compound, TM -50 Double-end esters containing double bonds are provided by Shanghai Zhongcheng Fine Chemical Co., Ltd.; organosiloxane QD-13 and QD-15 are provided by Shanghai Qida Industry and Trade Company; potassium persulfate and ammonium persulfate are provided by Shanghai Provided by Shijian Industrial Co., Ltd.; sodium bicarbonate, supplied by Changzhou Hengrun Chemical Co., Ltd.

[0091] Provided, AP-95 and...

Embodiment 2

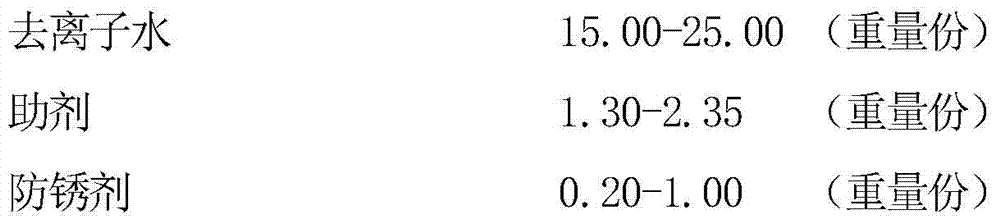

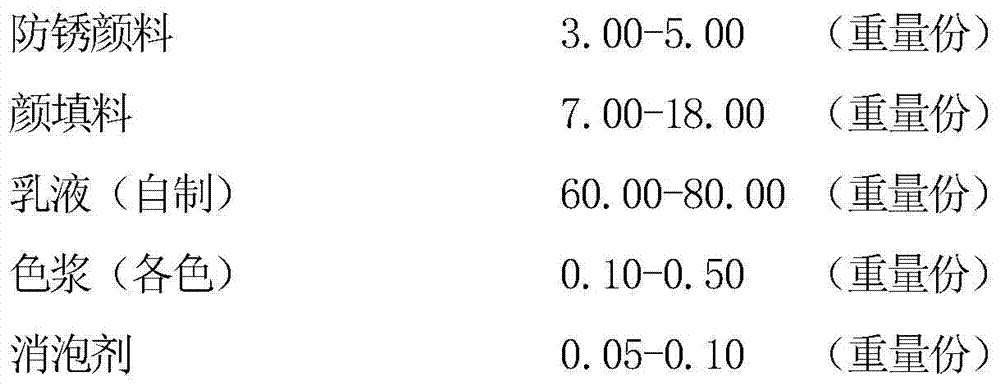

[0123] Example 2: Preparation and performance testing of water-based steel structure anti-corrosion aqueous dispersion coating

[0124] 1. Raw material

[0125] Wetting and dispersing agents (BYK-199, BYK-187), rheological agents (BYK-184, AQUATlX 8421), defoamers (BYK-025, BYK-1610), from BYK Chemical Technology Consulting (Shanghai) Co., Ltd. Provided; propylene glycol butyl ether, propylene glycol, provided by Shanghai Chemical Reagent Company; antirust agent (SAB), provided by Nuocheng Chemical Industry Co., Ltd.; L10 environment-friendly antirust agent, provided by Shanghai Lika Environmental Technology Co., Ltd.; JRL- 103 steel passivation agent, provided by Shanghai Songhang Trade Development Co., Ltd.; JA-589 antirust agent, provided by Changsha Jinao Company; preservatives (K10Sa, A2W, DB305, B 20, lTH2), provided by Shanghai Chaoling Trade Co., Ltd.; water-based UV absorber, provided by Shanghai Anhui Chemical; anti-rust pigment (TP-30 aluminum tripolyphosphate, S-8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com