Dry-cut cotton fiber bio-enzyme pulping process

A cotton fiber and biological enzyme technology, which is applied in fiber raw material treatment, pulp bleaching, raw material pretreatment for fine splitting, etc., can solve the problems of ineffective removal of raw material impurities, hidden safety hazards in the use of pressure vessels, and excessive use of chemicals. The effect of improving bleachability and evenness, reducing pulping costs and improving paper quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The present embodiment provides a dry cut cotton fiber biological enzyme pulping process, which comprises the following steps:

[0051] 1. Dry material preparation system

[0052] The system used in the dry material preparation process includes a cleaning system, cotton fiber longitudinal finishing equipment and a cutting machine. machine connected.

[0053] The working width of the cotton fiber longitudinal finishing equipment (carding machine) is more than 1.5m.

[0054] The number of moving blades of the cutting machine is 20-40 pieces.

[0055] The motor speed of the cutting machine is 1000 rpm.

[0056] The feeding speed of the conveyor belt is above 150m / min.

[0057] 2. Dry material preparation process

[0058] Raw material: comb noil, production capacity is 10 tons;

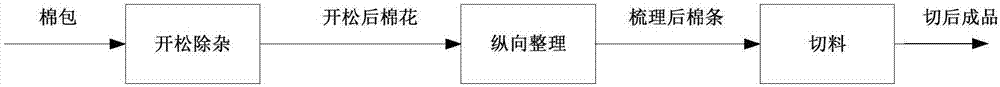

[0059] The dry material preparation process is realized by the above-mentioned dry material preparation system, and the dry material preparation process flow chart is as follows figure 1 As ...

Embodiment 2

[0075] The present embodiment provides a dry cut cotton fiber biological enzyme pulping process, which comprises the following steps:

[0076] Raw material: dry-cut cotton linters, containing 0.2-0.5wt% impurities (calculated based on the total weight of dry-cut cotton fibers);

[0077] First, put the dry-cut cotton linters into the steamer, add water to the steamer, then add wetting agent and pectinase, turn on the circulation pump, start heating up, stop heating when the temperature reaches 60°C, and start keeping warm. After 30 minutes of heat preservation, it can become a slurry;

[0078] Then, sodium hydroxide and hydrogen peroxide were added to the pretreated slurry, and the pretreated slurry was steamed and bleached at 85° C. for 40 minutes.

[0079] Based on the total weight of the dry cotton linters as 100%, the dosage of the pectinase is 0.3wt%, and the dosage of the wetting agent TC-1 is 0.02%;

[0080] In the pretreatment process, the mass ratio of the dry cuttin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com