Modular wood house wall structure and construction method thereof

A technology of wall structure and construction method, applied in the direction of walls, building components, building structures, etc., can solve the problems of difficult to achieve long-term durability of the wall, difficult to ensure air tightness, difficult to meet the requirements of wooden house walls, etc. Consumption, easy decomposition, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the implementation manners of the present invention are not limited thereto.

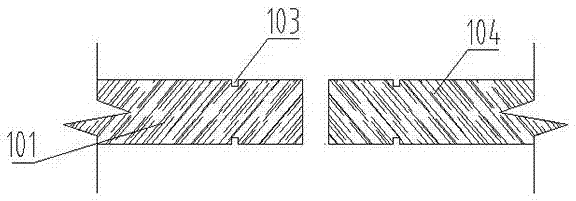

[0017] Such as figure 1 and figure 2 As shown, the present invention includes: double-sided wood board layer 1, cladding keel frame 3, thermal insulation layer 4, gypsum board 5, angle steel 303, bolt 304 and other fasteners, and the gypsum board 5 is located at the innermost side of the wall In contact with the indoor environment, the double-sided wood layer 1 includes an inner wood layer 101 and an outer wood layer 102, and the cladding frame 3 is composed of an inner frame 301 and an outer frame 302. The inner frame The layer 101 and the outer wood layer 102 are respectively connected to the inner cladding dragon skeleton 301 and the outer cladding dragon skeleton 302 through angle steels 303 and bolts 304, and the thermal insulation la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com