A method for growing polysilicon target material

A technology for growing polycrystalline and silicon targets, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of large differences, lack of control means for crystal production rate, large product size, etc., to improve crystal grains Size and uniformity, the effect is timely and obvious, and the effect of overcoming the large grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

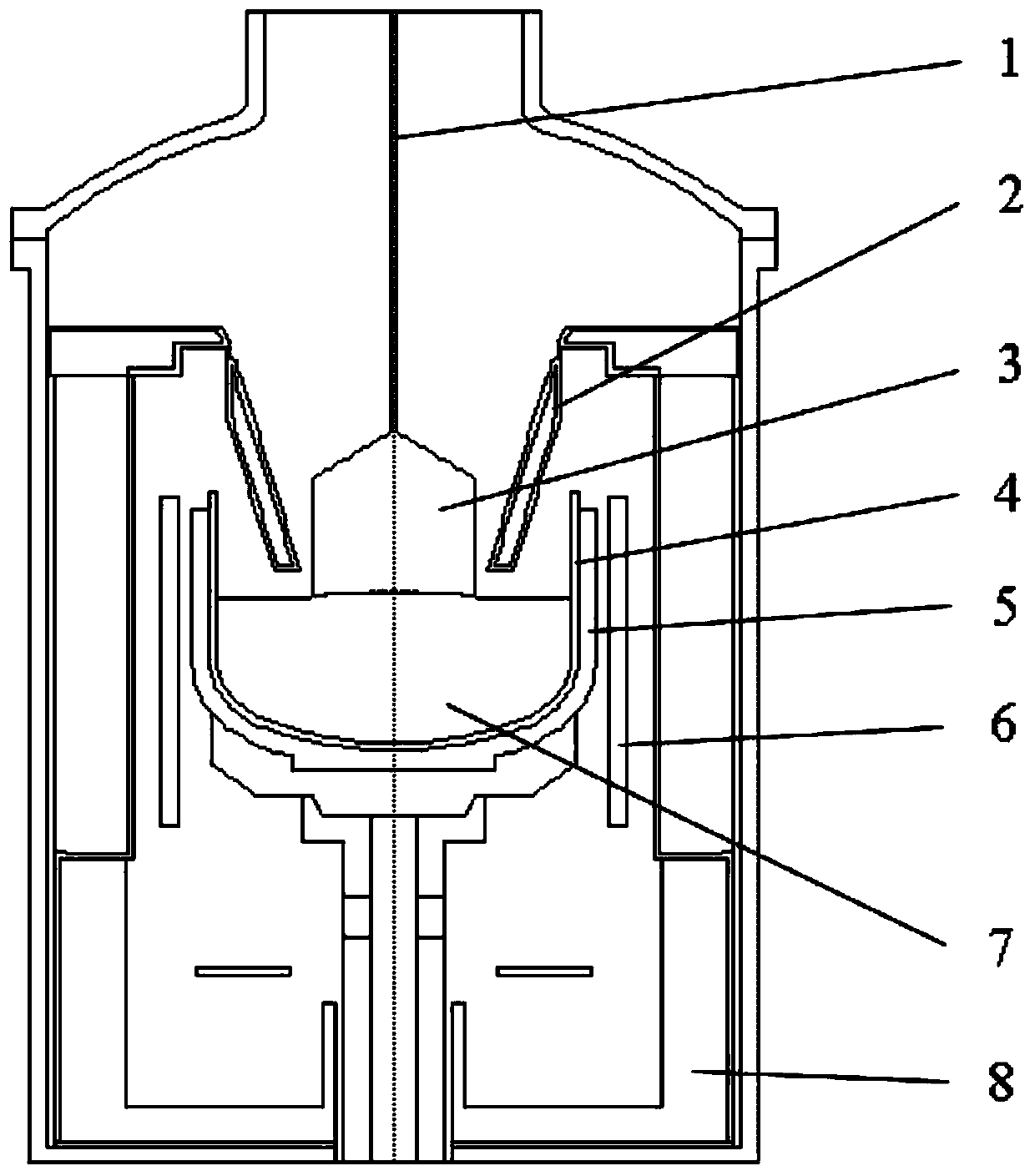

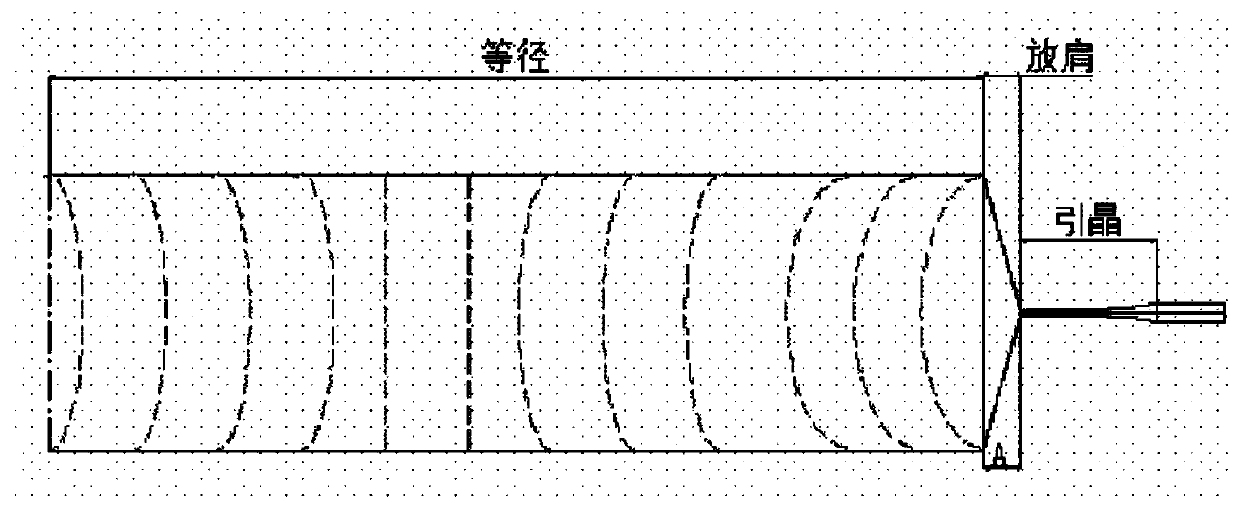

[0052] The crystal pulling furnace used in the method for growing a polysilicon target in this embodiment is a crystal pulling furnace of the model JRDL-900; the crystal pulling furnace includes a pulling device and a growth furnace part, and the pulling device includes a crystal lifting and rotating mechanism 1, The crystal ascending and rotating mechanism 1 is connected to the seed chuck through the seed rod, and the crystal ascending and rotating mechanism is used to pull the polysilicon 3; the cavity of the growth furnace part is provided with a guide tube 2, a quartz crucible 4, a graphite crucible 5 and a heater 6 , the quartz crucible 4 is placed in the graphite crucible 5, heated by the heater 6, the polysilicon raw material is placed in the quartz crucible, and the molten silicon 7 is obtained after heating; an insulating material 8 is arranged outside the furnace cavity for heat preservation; The cylinder is used to improve the temperature field and flow field in the ...

Embodiment 2

[0079] The specific steps of the method in this embodiment are the same as in Example 1, and the required diameter of the designed product and the crystal orientation of the used seed crystal are also the same for , the difference is that:

[0080] The second step, chemicals:

[0081] Fill the crystal pulling furnace with argon gas at a flow rate of 100L / h until the furnace pressure is 3000Pa, then set the heating power to 180kw, and change the polysilicon raw material in the crystal pulling furnace. , to obtain molten silicon 7;

[0082] The third step, seeding:

[0083] After the polysilicon raw materials are prepared, the heating power electric control controller is adjusted to automatic, the heating power is reduced to the size required for seeding, the temperature is lowered to make the liquid level of the molten silicon 7 supercooled, and the seeding on the pulling device is reduced. crystal rod, so that the bottom surface of the seed crystal contacts the molten silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com