Crystallizer controlling crystal granularity through ultrasonic waves and crystallization method

A technology of crystallizer and ultrasonic wave, which is applied in the field of chemical industry, can solve the problems of increasing the operation process, destroying the crystal surface and crystal form by a large number of impurities, reducing product quality, etc., achieving high grinding efficiency, improving product quality, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

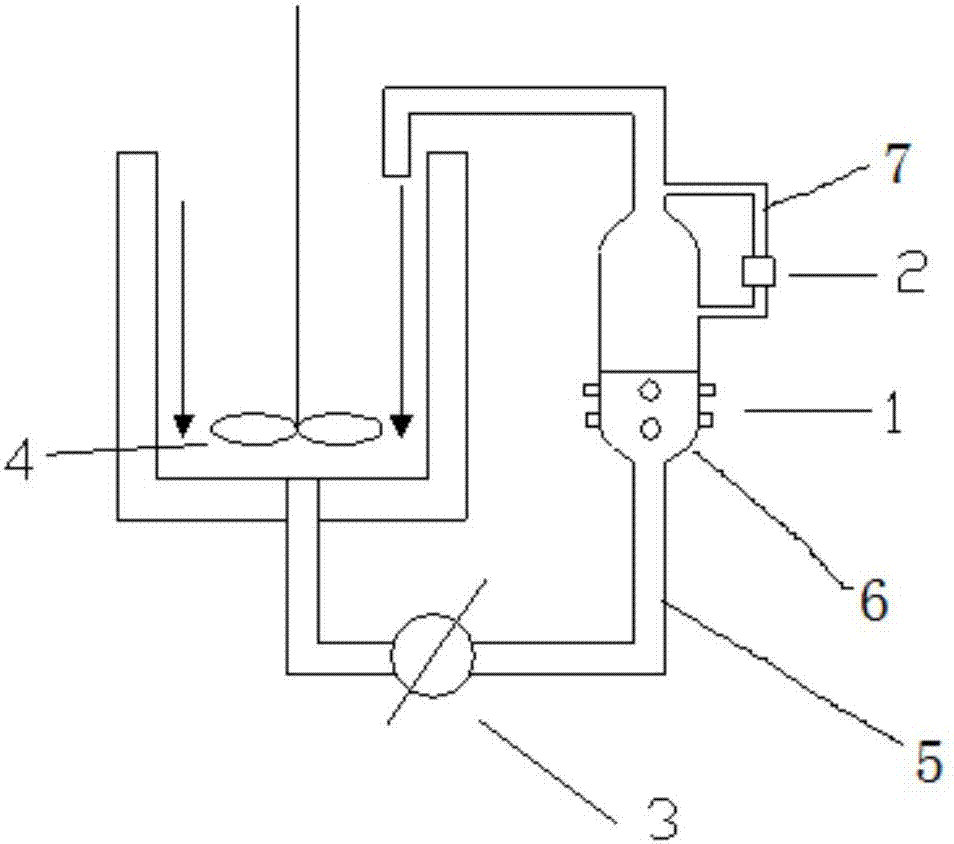

[0032] The whole crystallizer structure is as figure 1 As shown, wherein the volume of the crystallization mother liquid container is 120 liters, and the bottom of the settling tank is provided with eight 60W ultrasonic generators. In the crystallization mother liquid container, the roxithromycin crystal is cooled and crystallized by using the mixed liquid of ethanol and water as a solvent. 25 kilograms of roxithromycin were dissolved in a mixture of 50 kilograms of ethanol and 50 kilograms of water, and the intermittent elution crystallization experiment was carried out at a cooling rate of 0.4°C / min at a temperature of 75°C.

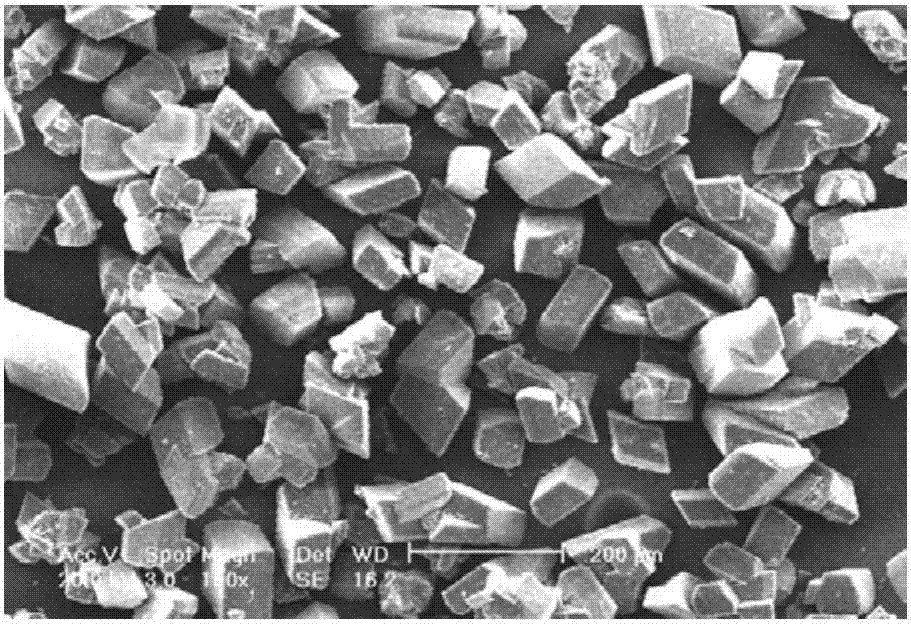

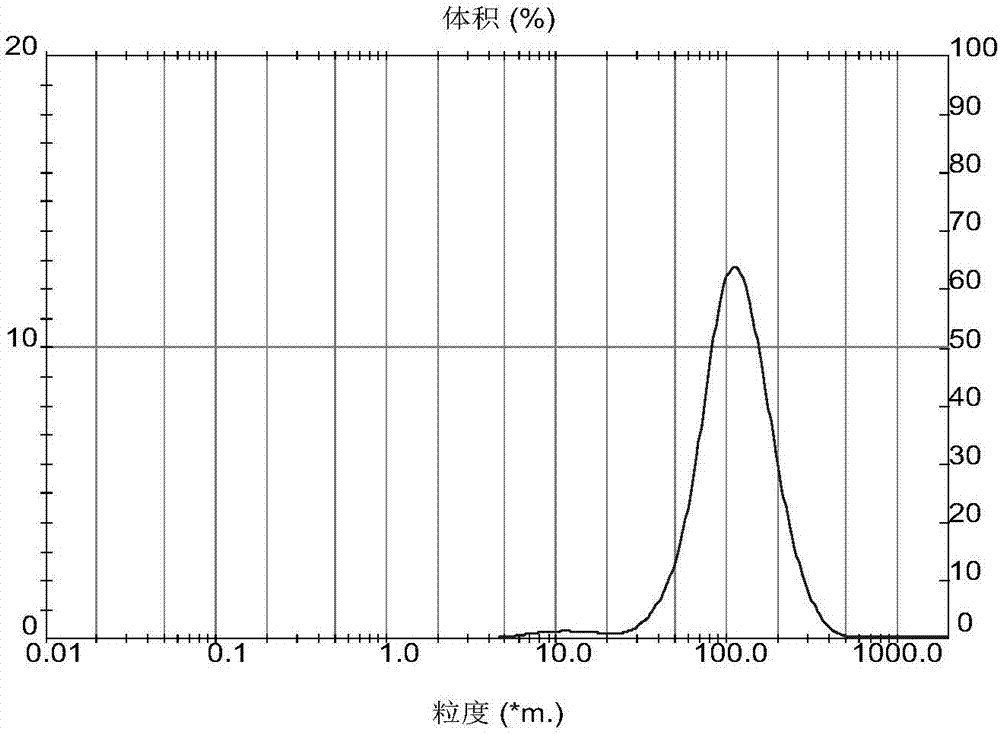

[0033] The crystal nuclei were naturally precipitated at 55°C. After 30 minutes of heat preservation, the temperature was lowered at a rate of 0.4°C / min. At the same time, the ultrasonic generator was turned on, and the circulation rate of the crystal slurry was 3.5L / min. After cooling down to 0°C, turn off the ultrasonic generator, but continue to ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com