Macroporous-mesoporous-microporous zinc oxide material and preparation method and application thereof

A technology of zinc oxide and zinc oxide particles, applied in chemical instruments and methods, zinc oxide/zinc hydroxide, material resistance, etc., can solve the problems of low diffusion efficiency and few reports of zinc oxide nanomaterials, and achieve no pollutants Enhanced emissions, diffusion effects, and performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A zinc oxide nanomaterial, its preparation method comprises the following steps:

[0040] 1) Weigh 0.2 g of zinc acetylacetonate and add it to 4 g of oleylamine, stir evenly to obtain a translucent solution;

[0041] 2) Heat the translucent solution obtained in step 1) to 250°C for constant temperature reaction for 60 minutes, condense and reflux during the reaction, and then cool naturally to obtain an off-white precipitate;

[0042] 3) The off-white precipitate obtained in step 2) is washed with ethanol three times on the centrifuge (centrifugal speed is 3000r / min), and then dispersed in hexane; the zinc oxide nanomaterial is obtained after standby.

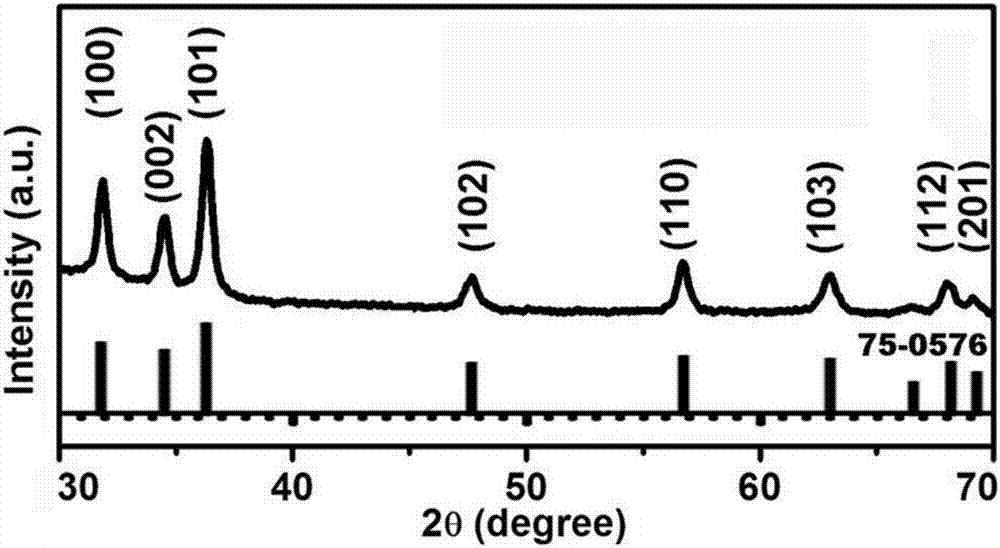

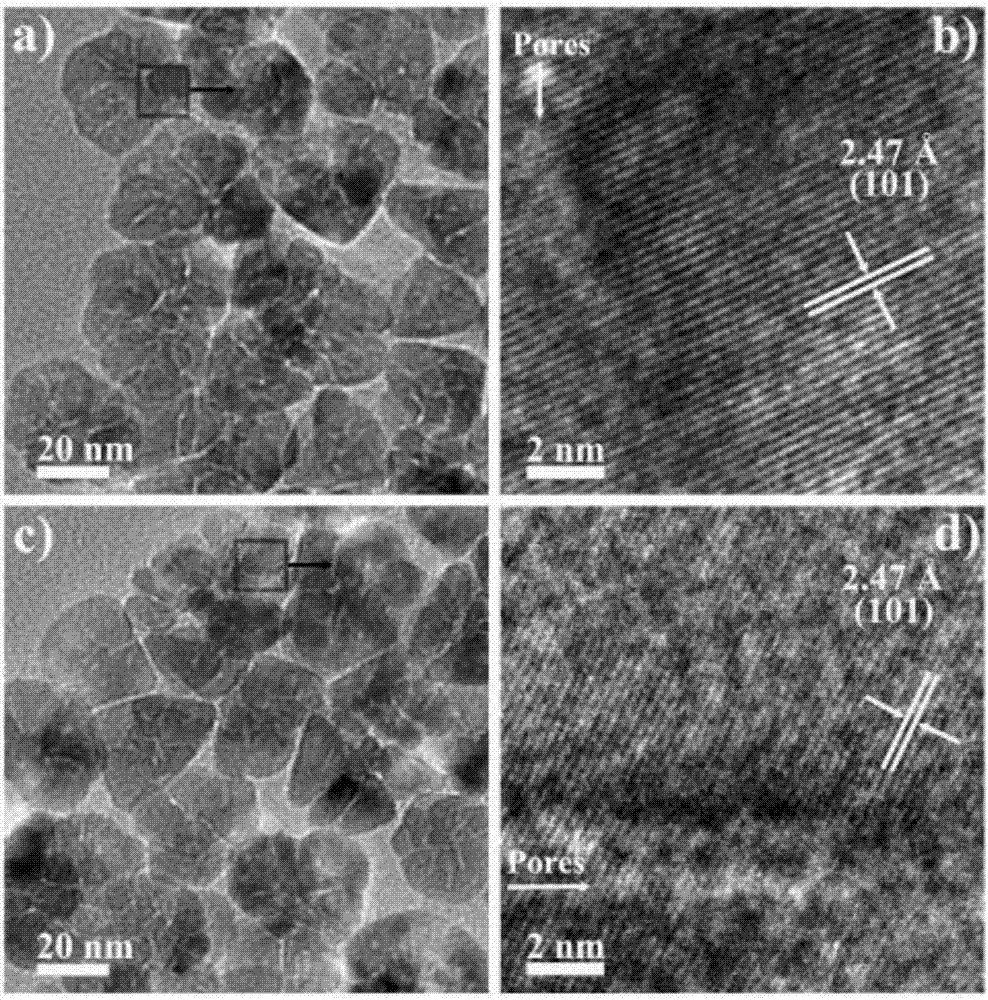

[0043] The product obtained in this embodiment is determined to be zinc oxide through X-ray diffraction analysis, and its X-ray diffraction pattern is shown in figure 1 ; Transmission electron microscopy (TEM) analysis shows that this product is a nanoparticle with many micropores, the particle size is 30nm, and its mic...

Embodiment 2

[0045] A kind of macroporous-mesoporous-microporous zinc oxide material, its preparation method comprises the following steps:

[0046] 1) Weigh 0.198g of zinc acetylacetonate and add it to 4g of oleylamine, stir evenly to obtain a translucent solution;

[0047] 2) Heat the translucent solution obtained in step 1) to 150°C and react at a constant temperature for 60 minutes, condense and reflux during the reaction, then cool naturally to obtain a grayish white precipitate; then wash 3 times with ethanol on the centrifuge (centrifugal speed: 3000r / min) to wash;

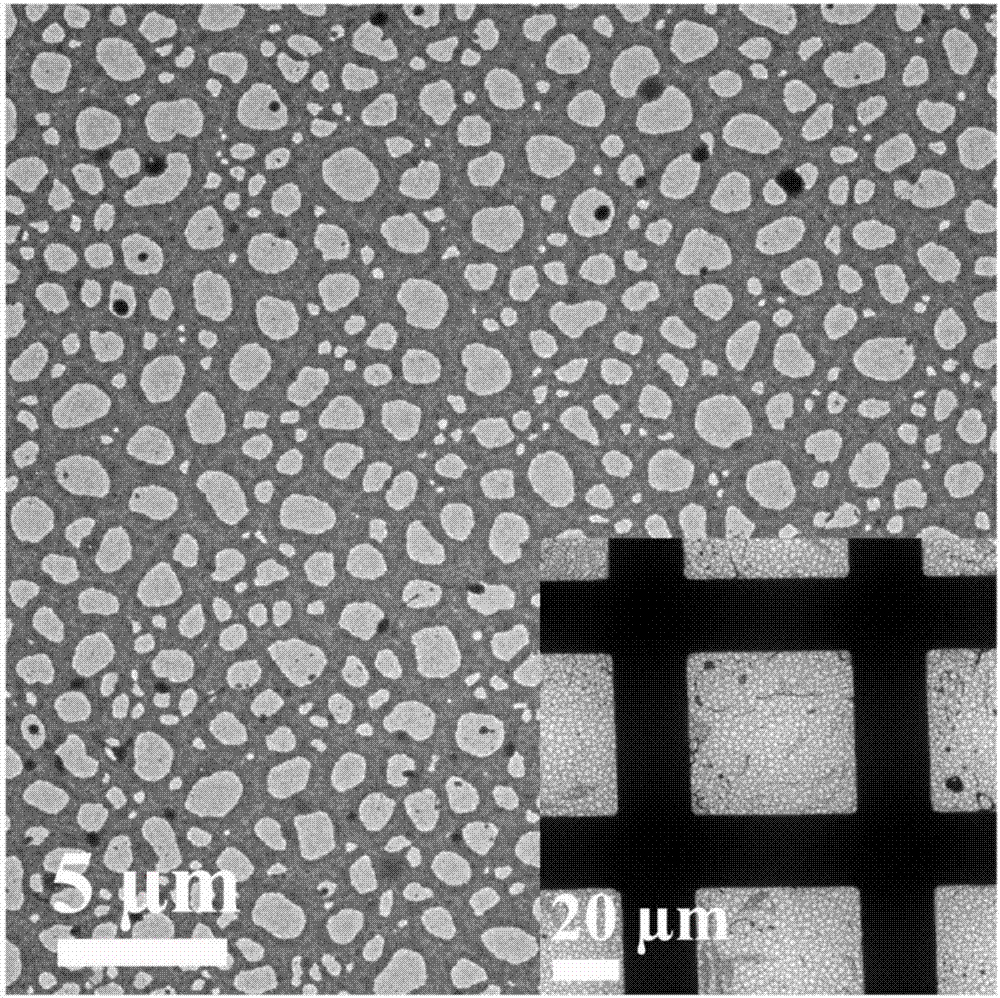

[0048] 3) Dispersing the gray-white precipitate obtained in step 2) in normal hexane to obtain a suspension, controlling the concentration of the gray-white precipitate in the suspension to be 0.25 mg / ml (the ratio of the amount of the gray-white precipitate in the suspension to the volume of normal hexane), and then Volatilize naturally at room temperature and atmospheric pressure, and self-assemble on the copper grid...

Embodiment 3

[0051] A kind of macroporous-mesoporous-microporous zinc oxide material, its preparation method comprises the following steps:

[0052] 1) Weigh 0.198g of zinc acetylacetonate and add it to 4g of oleylamine, stir for 15min to obtain a translucent solution;

[0053] 2) Heat the translucent solution obtained in step 1) to 150°C for constant temperature reaction for 60 minutes, condense and reflux during the reaction, then cool naturally to obtain a grayish white precipitate; then wash 3 times with ethanol on the centrifuge (centrifugal speed is 3000r / min) to wash;

[0054] 3) Dispersing the gray-white precipitate obtained in step 2) in normal hexane to obtain a suspension, controlling the concentration of the gray-white precipitate in the suspension to be 0.25 mg / ml (the ratio of the amount of the gray-white precipitate in the suspension to the volume of normal hexane), and then Under the environment of room temperature and atmospheric pressure, self-assembly is induced by natura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com