Washing machine groove cleaning agent

A washing machine tank and cleaning agent technology, applied in the field of cleaning agents, can solve the problems of less research on metal protective agents, damage, and weak effect of inorganic corrosion inhibitors, so as to achieve enhanced decontamination and metal protection effects, avoiding secondary pollution, and good The effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

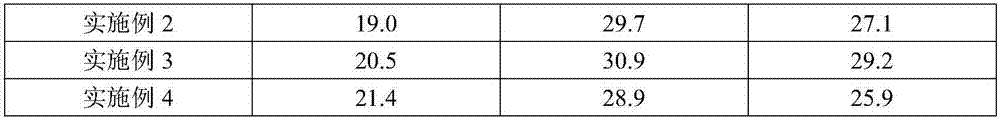

Embodiment 1

[0019] Embodiment 1, washing machine tank cleaner of the present invention

[0020] Formula: 500g of sodium carbonate, 300g of sodium percarbonate, 40g of tetraacetylethylenediamine, 20g of binary compound enzyme (the weight ratio of lipase and protease is 1:2), 30g of sodium α-alkenyl sulfonate, 50g of calcium carbonate and Metal protective agent 60g (the weight ratio of chitosan and calcium gluconate is 2:1).

[0021] Preparation: Mix sodium carbonate, sodium percarbonate, tetraacetylethylenediamine, binary compound enzyme, sodium α-alkenyl sulfonate, calcium carbonate and metal protective agent, and stir evenly.

Embodiment 2

[0022] Embodiment 2, washing machine tank cleaner of the present invention

[0023] Formula: 580g of sodium carbonate, 200g of sodium percarbonate, 20g of tetraacetylethylenediamine, 10g of binary compound enzyme (the weight ratio of lipase and protease is 1:2), 40g of sodium α-alkenyl sulfonate, 60g of calcium carbonate and Metal protection agent 90g (the weight ratio of chitosan oligosaccharide and calcium gluconate is 4:1).

[0024] Preparation: Mix sodium carbonate, sodium percarbonate, tetraacetylethylenediamine, binary compound enzyme, sodium α-alkenyl sulfonate, calcium carbonate and metal protective agent, and stir evenly.

Embodiment 3

[0025] Embodiment 3, washing machine tank cleaner of the present invention

[0026] Formula: 550g of sodium carbonate, 240g of sodium percarbonate, 30g of tetraacetylethylenediamine, 10g of binary compound enzyme (the weight ratio of lipase and protease is 1:2), 30g of sodium α-alkenyl sulfonate, 60g of calcium carbonate and Metal protective agent 80g (the weight ratio of chitosan and calcium gluconate is 3:1).

[0027] Preparation: Mix sodium carbonate, sodium percarbonate, tetraacetylethylenediamine, binary compound enzyme, sodium α-alkenyl sulfonate, calcium carbonate and metal protective agent, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com