Self-repairing macromolecule nanometer tyre cement and preparation method thereof

A polymer, self-healing technology, used in non-polymer adhesive additives, non-polymer organic compound adhesives, adhesives, etc. problems, to achieve the effect of high bond strength, long service life, and not easy to age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

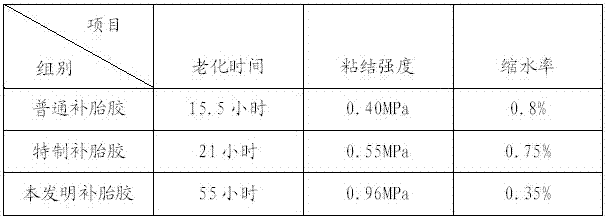

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A self-repairable polymer nano tire sealant, made of the following raw materials in parts by weight, including 15 parts of acrylic acid, 8 parts of quartz powder, 13 parts of nonylphenol, 9 parts of ammonium hydroxide, and 4 parts of nano-zinc oxide , 13 parts of nano-silica sol, 20 parts of isocyanate, 3 parts of trichlorofluoromethane, 5 parts of water glass, 22 parts of amino resin, 6 parts of sorbitan monooleate, 12 parts of ammonium polyphosphate, 5 parts of zinc borate , 7 parts of methyl amyl alcohol, 13 parts of nano activated carbon, 16 parts of vinyl acetate, 22 parts of cobalt soap, 12 parts of isononanoic acid, 18 parts of polyurethane, 6 parts of titanium dioxide, 13 parts of trichlorethylene and 24 parts of dibasic acid ester .

[0024] A preparation method of a self-repairable polymer nano tire sealant, comprising the following steps:

[0025] 1) Mix 15 parts of acrylic acid, 8 parts of quartz powder, 13 parts of nonylphenol, 9 parts of ammonium hydroxid...

Embodiment 2

[0032]A self-repairable polymer nano tire sealant, made of the following raw materials in parts by weight, including 18.5 parts of acrylic acid, 9 parts of quartz powder, 15.5 parts of nonylphenol, 12 parts of ammonium hydroxide, and 6 parts of nano-zinc oxide , 14.5 parts of nano-silica sol, 22 parts of isocyanate, 5 parts of trichlorofluoromethane, 10 parts of water glass, 23 parts of amino resin, 8 parts of sorbitan monooleate, 13.5 parts of ammonium polyphosphate, 6.5 parts of zinc borate , 9 parts of methyl amyl alcohol, 15.5 parts of nano activated carbon, 18 parts of vinyl acetate, 23 parts of cobalt soap, 14 parts of isononanoic acid, 19 parts of polyurethane, 8 parts of titanium dioxide, 15.5 parts of trichlorethylene and 26 parts of dibasic acid ester .

[0033] A preparation method of a self-repairable polymer nano tire sealant, comprising the following steps:

[0034] 1) Mix 18.5 parts of acrylic acid, 9 parts of quartz powder, 15.5 parts of nonylphenol, 12 parts ...

Embodiment 3

[0041] A self-repairable polymer nano tire sealant, made of the following raw materials in parts by weight, including 22 parts of acrylic acid, 10 parts of quartz powder, 18 parts of nonylphenol, 15 parts of ammonium hydroxide, and 8 parts of nano-zinc oxide , 16 parts of nano-silica sol, 24 parts of isocyanate, 7 parts of trichlorofluoromethane, 15 parts of water glass, 24 parts of amino resin, 10 parts of sorbitan monooleate, 15 parts of ammonium polyphosphate, 8 parts of zinc borate , 11 parts of methyl amyl alcohol, 18 parts of nano activated carbon, 20 parts of vinyl acetate, 24 parts of cobalt soap, 16 parts of isononanoic acid, 22 parts of polyurethane, 10 parts of titanium dioxide, 18 parts of trichlorethylene and 28 parts of dibasic acid ester .

[0042] A preparation method of a self-repairable polymer nano tire sealant, comprising the following steps:

[0043] 1) Mix 22 parts of acrylic acid, 10 parts of quartz powder, 18 parts of nonylphenol, 15 parts of ammonium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com