Method for continuously catching CO2 in cement kiln flue gas with hydrate method

A cement kiln and hydrate technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of inability to achieve continuous absorption, insufficient separation capacity, and low degree of energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

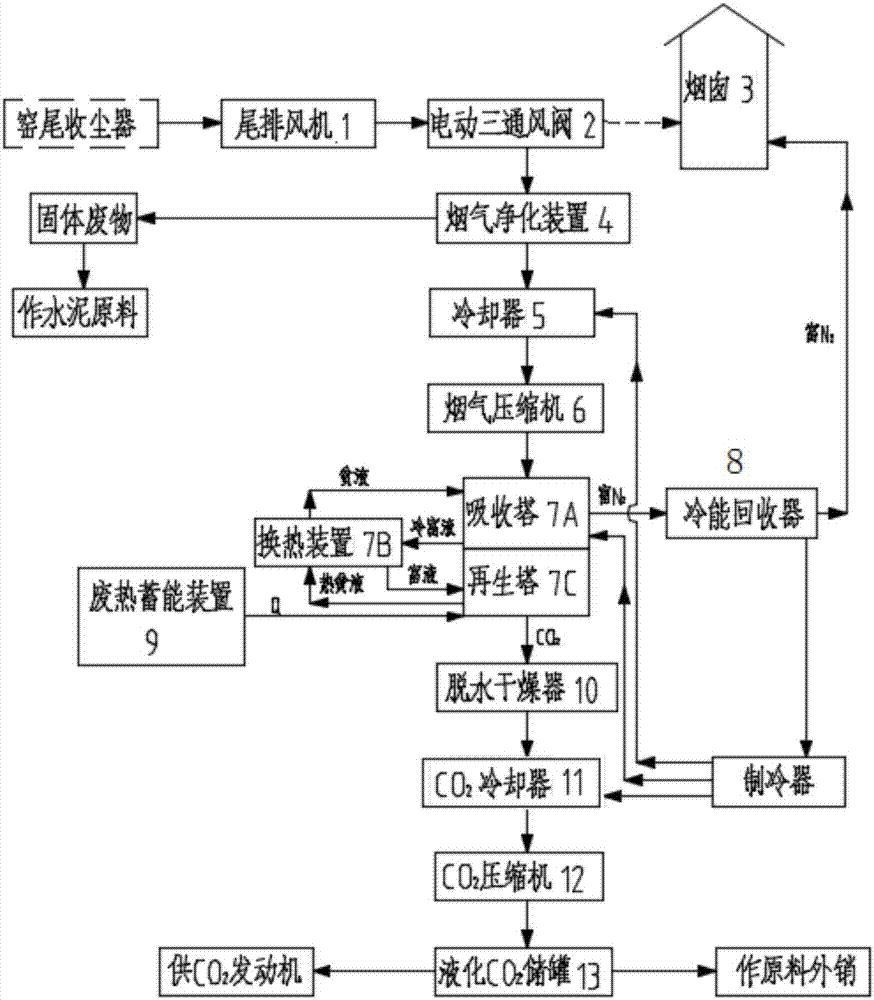

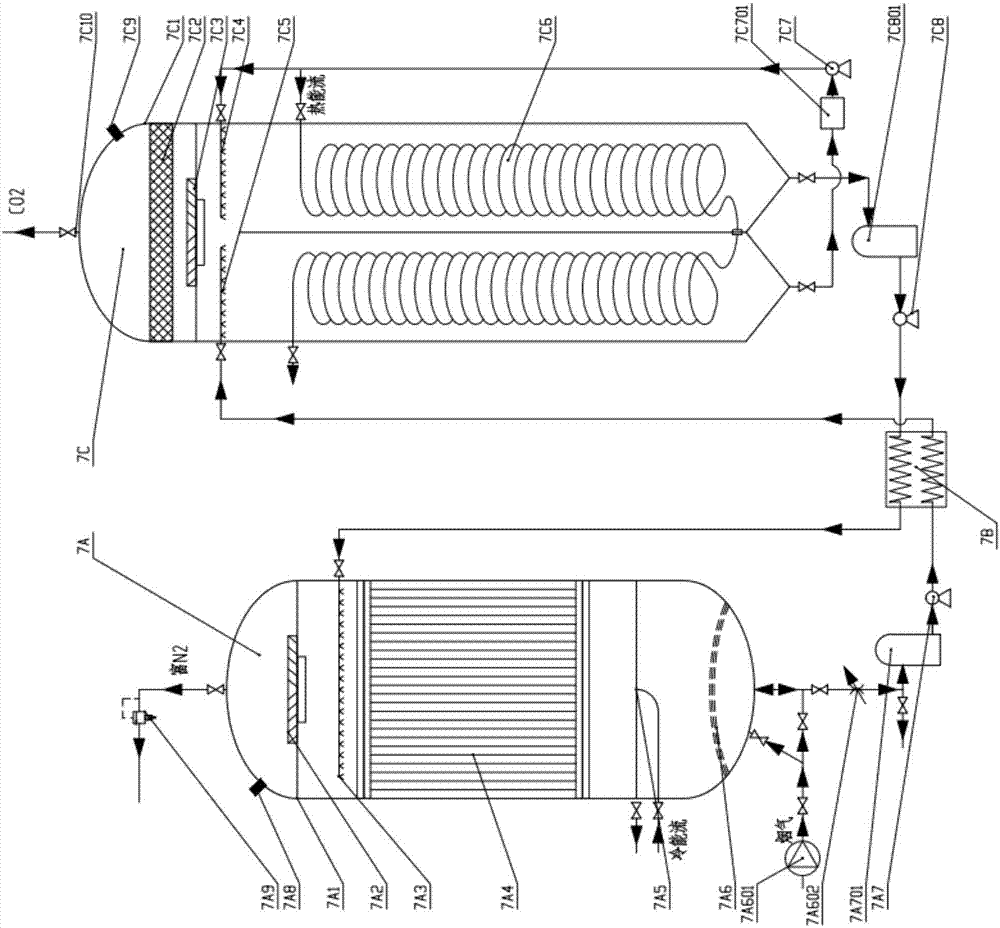

[0054] like Figures 1 to 3 As shown, the tail exhaust fan 1 connected to the dust collector at the kiln tail continuously sends the flue gas into the flue gas pipe, and the electric three-ventilation valve 2 is set on the flue gas pipe between the tail exhaust fan 1 connected to the dust collector at the kiln tail and the chimney 3 , the flue gas enters the flue gas purification device 4 through the first exhaust port of the electric three-ventilation valve 2, and the purified flue gas separated from the flue gas purification device 4 enters the cooler 5 for cooling, and then enters the flue gas compressor 6 for further processing. Compression, the compressed purified flue gas enters the CO 2 Absorption tower - regeneration tower unit, the purified flue gas in CO 2 Absorption of CO from the regeneration unit 2 In the absorption tower 7A, from the inlet of the gas distribution and liquid discharge device 7A6 at the bottom of the absorption tower 7A, it flows upwards through ...

Embodiment 2

[0061] When the dust content of the flue gas from the dust collector at the end of the kiln of the cement plant is lower than 20mg / nm 3 And when there are no heavy metal pollutants, the difference from Example 1 is that the flue gas purification treatment step is canceled, the flue gas exiting the dust collector at the end of the kiln is suctioned and blown in by the tail exhaust fan, and the electric air valve is switched and sent to the cooler for cooling. Compressed continuously by compressor and sent to CO 2 Continuous capture of CO by hydrate method in absorption tower 2 .

Embodiment 3

[0063] During processing, in order to be able to provide more pure CO 2 , the difference from Example 1 is: using another CO in series 2 Absorber - Regenerative Tower Unit, Even More CO 2 Absorption tower - regeneration tower unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com