A hydrate method for continuous capture of CO in cement kiln flue gas 2 Methods

A cement kiln and hydrate technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of inability to achieve continuous absorption, insufficient separation capacity, and low degree of energy saving.

Active Publication Date: 2019-10-01

长沙紫宸科技开发有限公司

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This hydrate method has no serious secondary pollution caused by the traditional chemical adsorption method or physical chemical adsorption method, but there are still the following problems: it needs to react for several hours in a closed high-pressure reactor under high-pressure stirring, and the reaction time for hydrate formation It is still too long; the hydration reaction needs to be carried out under electromagnetic stirring in a closed high-pressure container, and the continuous absorption of CO in the flue gas flow cannot be achieved.

2

; Produced CO

2

The energy consumption of compressing into a liquid state is too high, and the separation capacity is insufficient

The device uses boiler recovery waste heat as energy to reduce CO in cement kiln exhaust gas

2

The capture of a large amount of high temperature and high pressure waste heat is not well utilized, and the degree of energy saving is not high, which has certain limitations

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

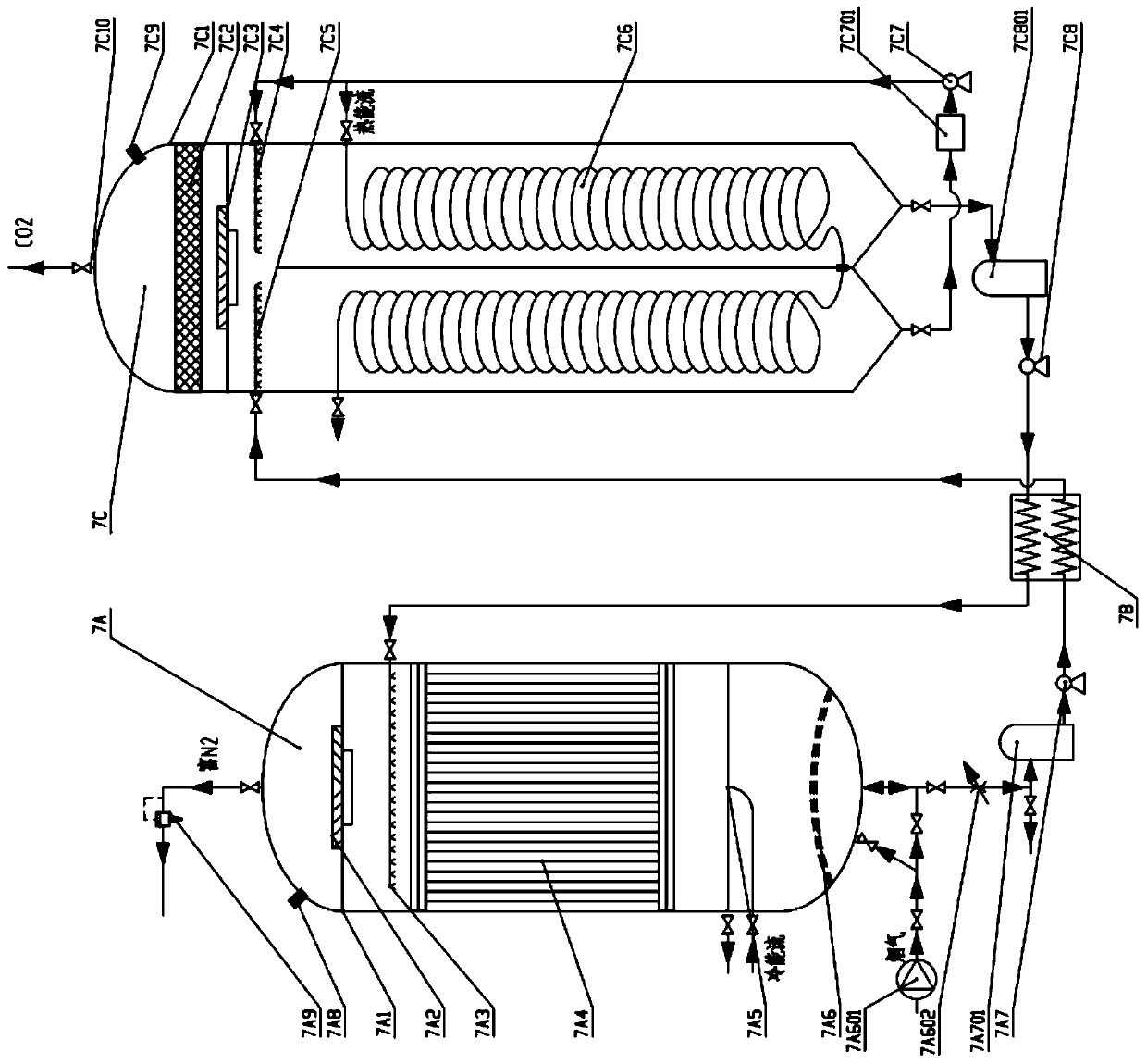

The invention provides a method for continuously catching CO2 in cement kiln flue gas with a hydrate method. The method comprises the following steps: continuously catching, curing, separating CO2 in continuously-flowing flue gas stream by taking a hydrate promoter solution as a catching agent and taking a large amount of waste residual heat generated in a cement production process as an energy source through a CO2 absorbing tower-regeneration tower unit comprising a silk screen catching bed device, and enriching a CO2 hydrate and continuously separating and discharging N2-enriched gas flow to realize continuous catching; continuously enriching caught CO2 hydrate rich liquor, transferring the enriched CO2 hydrate rich liquor into a regeneration tower for performing continuous separating and releasing to obtain continuous CO2 gas flow, and recycling hydrate poor liquor obtained by continuous separating and releasing; drying, cooling, compressing and storing the CO2 being subjected to continuous separating and releasing. By adopting the method, the CO2 in the cement kiln flue gas is continuously caught efficiently at low cost by using a part of process equipment on a cement production line and waste residual heat generated in the cement production process, so that the technical problem that only intermittent high-pressure air-tight catching is available and continuous catching is unavailable in a process of catching CO2 with a hydrate is solved.

Description

technical field The invention relates to the field of environmental protection and low-carbon technology, in particular to a hydrate method for continuously capturing CO in cement kiln flue gas 2 Methods. Background technique Climate change has become one of the issues affecting human survival and development, and carbon dioxide emitted by industry is considered to be the main cause of climate warming. As the largest developing country in the world, our country uses coal as its primary energy and thermal power as its secondary energy as its energy structure. With the rapid growth of economic aggregate, the CO of primary energy and secondary energy 2 Emissions have the characteristics of fast growth and large total volume, but the high investment and high capture cost of the current carbon emission reduction and climate change CCS or CCUS technology have become a serious obstacle to popularization and application. The existing research and demonstration applications of CCS...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01D53/62B01D53/96B01D53/79

CPCB01D53/343B01D53/62B01D53/96B01D2257/504B01D2258/0233B01D2259/124Y02A50/20Y02C20/40

Inventor 尹小林

Owner 长沙紫宸科技开发有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com