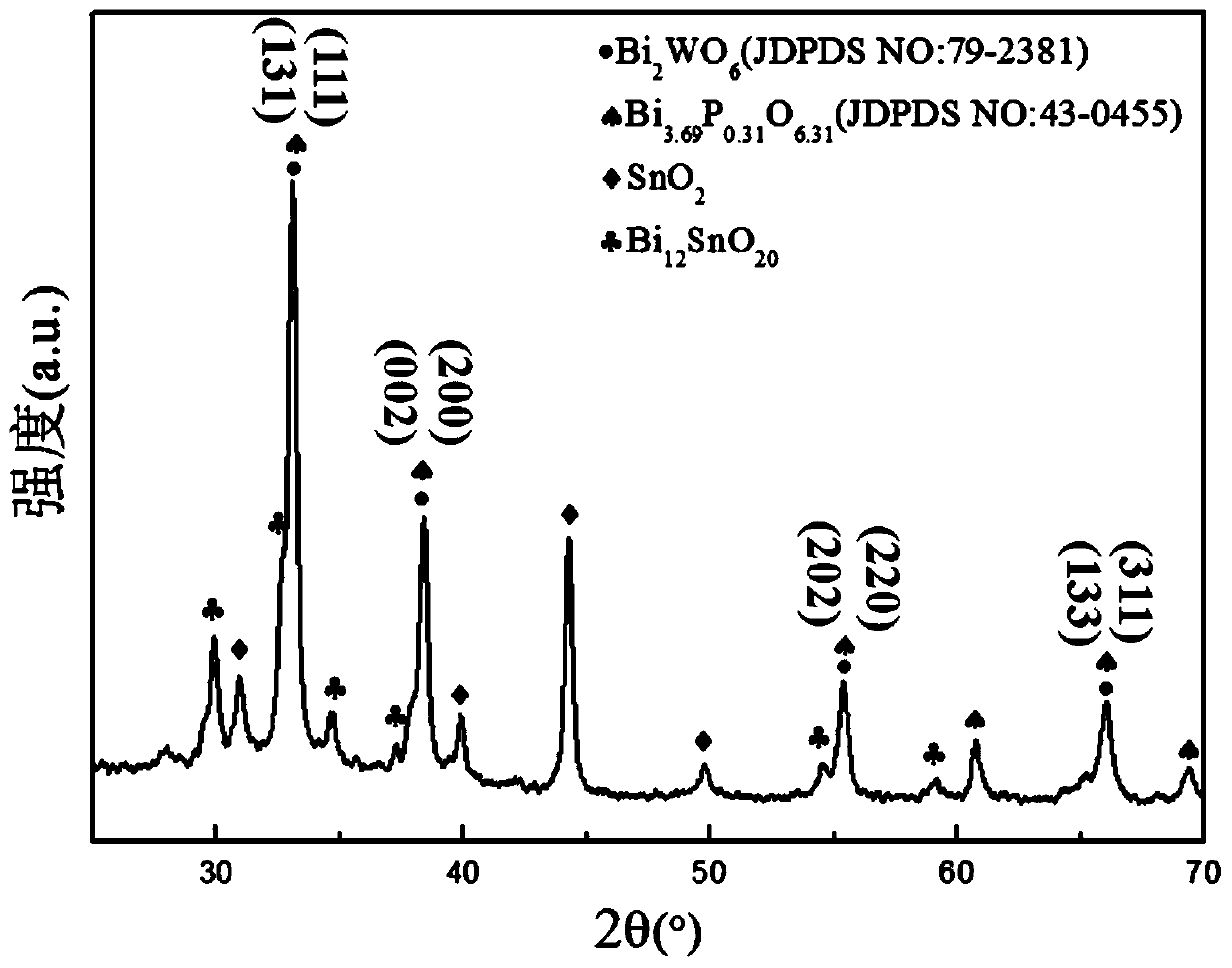

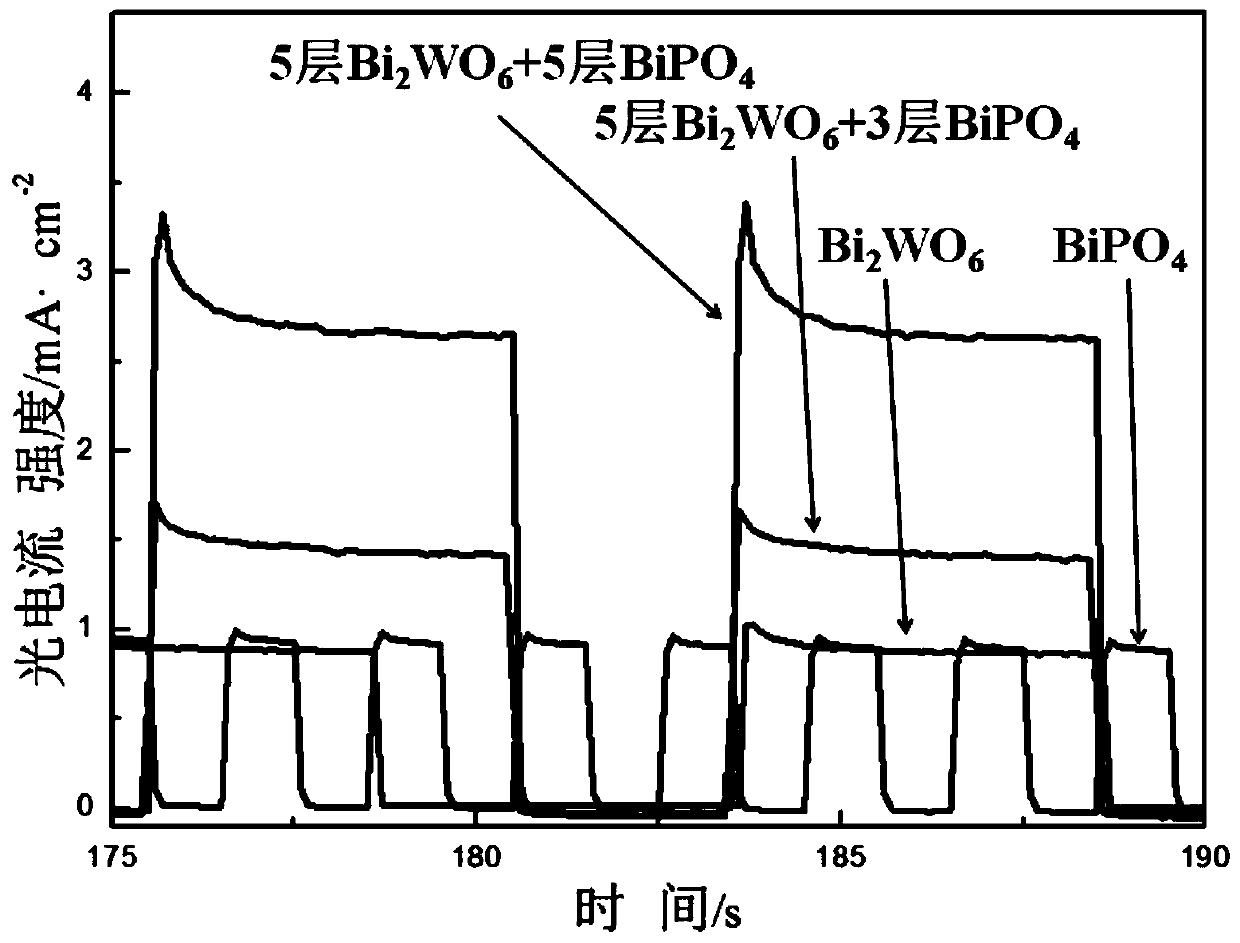

A kind of bismuth tungstate/bismuth phosphate composite thin film and its preparation method and application

A composite film, bismuth phosphate technology, applied in chemical instruments and methods, chemical/physical processes, light water/sewage treatment, etc., to achieve the effects of improving degradation efficiency, separation efficiency, and film uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step 1: The raw material Na 2 WO 4 Dissolve in ethylene glycol, prepare a 0.30mol / L solution, record it as solution A, add Bi(NO 3 ) 3 Dissolve in ethylene glycol and prepare a 0.60mol / L solution, denoted as solution B. According to the molar ratio of Bi to W of 2:1, add solution A to solution B slowly and stir vigorously to make it colorless Clarified Bi 2 WO 6 Solution, continue to stir for 1h to make it evenly mixed to obtain Bi 2 WO 6 Precursor solution; Bi 2 WO 6 The precursor solution is allowed to stand for 12h to obtain colorless and clear Bi 2 WO 6 Sol (remains colorless and clear after aging);

[0039] Step 2: Clean the cut FTO glass substrate and irradiate it under ultraviolet light to make the surface of the FTO glass substrate achieve atomic cleanliness;

[0040] Step 3: Spin coating Bi on the clean FTO glass substrate by spin coating 2 WO 6 Sol, the homogenization speed is 4000r / min, the homogenization time is 8s, and Bi 2 WO 6 Wet film. Will Bi 2 WO 6 The wet ...

Embodiment 2

[0046] Step 1: The raw material Na 2 WO 4 Dissolve in ethylene glycol, prepare a 0.30mol / L solution, record it as solution A, add Bi(NO 3 ) 3 Dissolve in ethylene glycol and prepare a 0.60mol / L solution, denoted as solution B. According to the molar ratio of Bi to W as 2:1, add solution A to solution B slowly and stir vigorously to make it colorless Clarified Bi 2 WO 6 Solution, continue to stir for 1.1h to make it evenly mixed to obtain Bi 2 WO 6 Precursor solution; Bi 2 WO 6 The precursor solution is allowed to stand for 12h to obtain colorless and clear Bi 2 WO 6 Sol (remains colorless and clear after aging);

[0047] Step 2: Clean the cut FTO glass substrate and irradiate it under ultraviolet light to make the surface of the FTO glass substrate achieve atomic cleanliness;

[0048] Step 3: Spin coating Bi on the clean FTO glass substrate by spin coating 2 WO 6 Sol, the homogenization speed is 3900r / min, the homogenization time is 7s, and Bi 2 WO 6 Wet film. Will Bi 2 WO 6 The we...

Embodiment 3

[0054] Step 1: The raw material Na 2 WO 4 Dissolve in ethylene glycol, prepare a 0.28mol / L solution, record it as solution A, add Bi(NO 3 ) 3 Dissolve in ethylene glycol and prepare a 0.56mol / L solution, denoted as solution B, according to the molar ratio of Bi to W of 2:1, slowly drop solution A into solution B and stir vigorously to make it colorless Clarified Bi 2 WO 6 Solution, continue to stir for 1.2h to make it evenly mixed to obtain Bi 2 WO 6 Precursor solution; Bi 2 WO 6 The precursor solution is allowed to stand for 11.5h to obtain colorless and clear Bi 2 WO 6 Sol (remains colorless and clear after aging);

[0055] Step 2: Clean the cut FTO glass substrate and irradiate it under ultraviolet light to make the surface of the FTO glass substrate achieve atomic cleanliness;

[0056] Step 3: Spin-coating Bi on the clean FTO glass substrate by spin-coating 2 WO 6 Sol, the homogenization speed is 3800r / min, the homogenization time is 7.5s, and Bi 2 WO 6 Wet film. Will Bi 2 WO 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com