Hydrogenation treatment process for sulfur-containing/high-sulfur crude oil

A technology for hydrotreating and high-sulfur crude oil, which is applied in the treatment of hydrocarbon oil, petroleum industry, refined hydrocarbon oil, etc., and can solve problems such as the inability to meet the processing requirements of sulfur-containing crude oil, so as to save investment costs, reduce equipment investment, and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

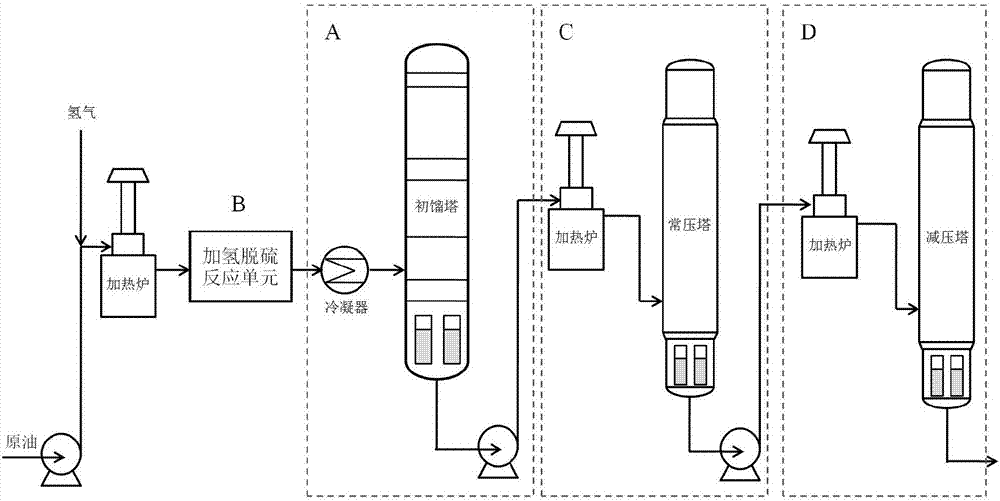

[0035] A hydrotreating process for sour / high sulfur crude oil, such as figure 1 As shown, the crude oil is desulfurized through the hydrodesulfurization reaction unit (B) before the initial distillation tower (A).

[0036] The reactor in the hydrodesulfurization reaction unit (B) is a three-stage fixed-bed reactor.

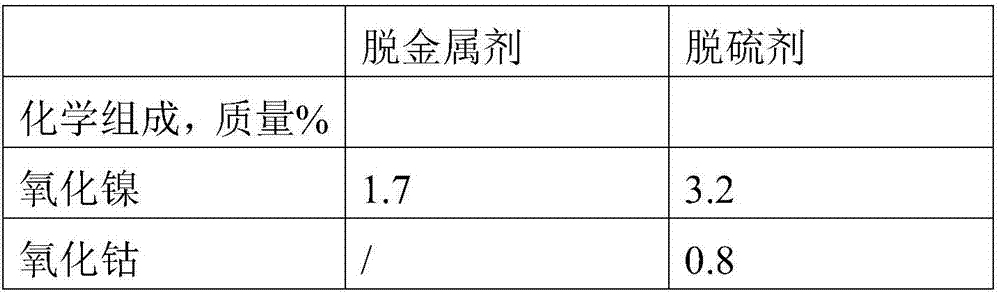

[0037] The crude oil treating agent in the reactor in the hydrodesulfurization reaction unit (B) is a hydroprotecting agent, a hydrodemetallizing agent and a hydrodesulfurizing agent.

[0038] The working process is as follows:

[0039] The desalted and dehydrated crude oil X is mixed with hydrogen, heated by a heating furnace to reach a reaction temperature of 320°C, and enters the hydroprocessing unit (B), where (B) is a three-stage fixed-bed reactor, which undergoes hydrogenation in sequence The protecting agent, the hydrodemetallizing agent and the hydrodesulfurizing agent are subjected to hydrodesulfurization treatment in the presence of a catalyst.

[004...

Embodiment 2

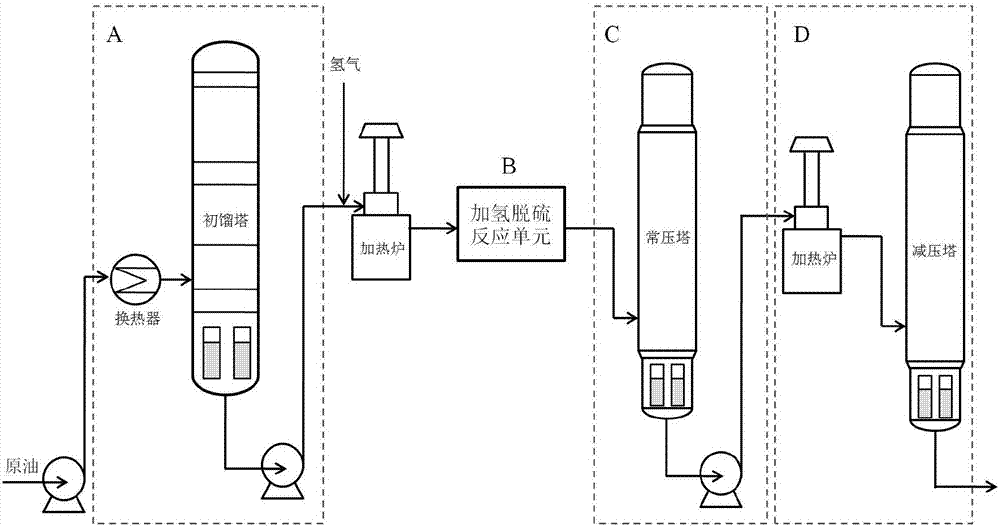

[0049] A hydrotreating process for sour / high sulfur crude oil, such as figure 2 It is shown that a hydrodesulfurization reaction unit (B) is added between the initial distillation tower (A) and the atmospheric tower (C) to desulfurize the crude oil.

[0050] The reactor in the hydrodesulfurization reaction unit (B) is a three-stage fixed-bed reactor.

[0051] The crude oil treating agent in the reactor in the hydrodesulfurization reaction unit (B) is a hydroprotecting agent, a hydrodemetallizing agent and a hydrodesulfurizing agent.

[0052] Crude oil X after desalination and dehydration treatment enters the primary distillation tower (A) after heat exchange with steam, the inlet temperature is 210°C, the top oil is obtained from the top of the tower, and part of the primary top oil component enters the storage tank or enters the downstream process after cooling. The other part is refluxed to the initial distillation tower; the initial side oil is obtained in the tower; the ...

Embodiment 3

[0059] A hydrotreating process for sour / high sulfur crude oil, such as figure 1 It shows that a hydrodesulfurization reaction unit (B) is added before the initial distillation tower (A) to desulfurize the crude oil.

[0060] The reactor in the hydrodesulfurization reaction unit (B) is a two-stage slurry bed reactor.

[0061] The crude oil treating agent in the reactor in the hydrodesulfurization reaction unit (B) is a hydrodemetallization agent and a hydrodesulfurization agent.

[0062] The desalted and dehydrated crude oil Y is mixed with hydrogen, heated by a heating furnace to reach a reaction temperature of 320°C, and then enters the hydroprocessing unit (B), where (B) is a three-stage fixed-bed reactor, which undergoes hydrogenation protection in sequence Agent, hydrodemetallization agent and hydrodesulfurization agent, in the presence of catalyst, carry out hydrodesulfurization treatment.

[0063] The product after hydrodesulfurization treatment is cooled and separated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com