Preparation method of Mo-SBA-15 molecular sieve and hydrogenation catalyst

A hydrogenation catalyst, mo-sba-15 technology, applied in molecular sieve catalysts, molecular sieves and base exchange compounds, chemical instruments and methods, etc., can solve the problems of low price, limited practical application, low specific surface area, etc. degree, improve the introduction efficiency, and increase the effect of the hydrothermal treatment temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

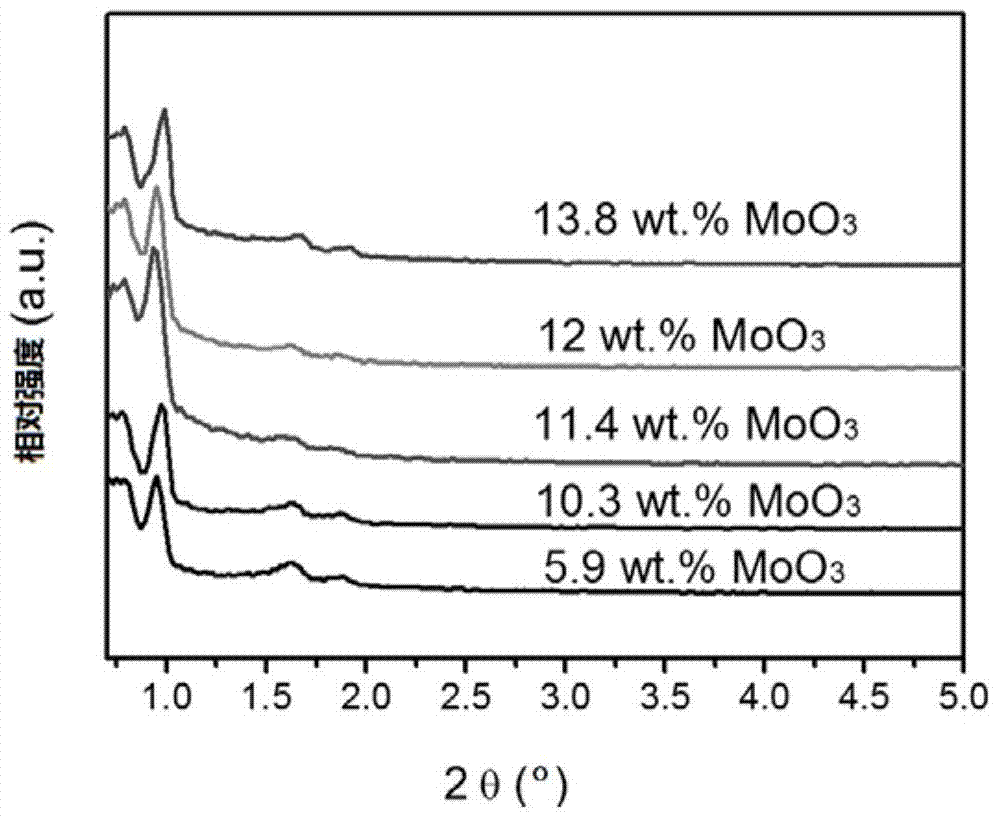

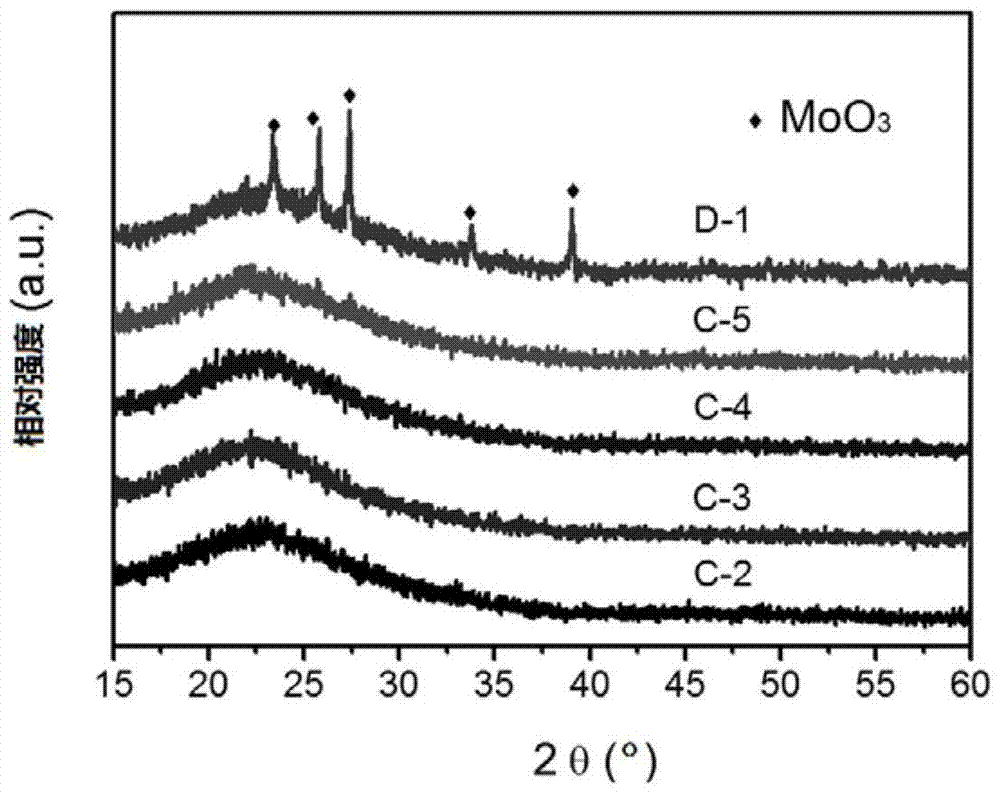

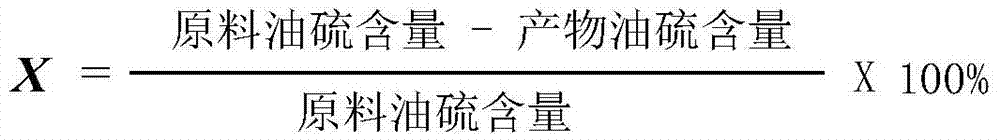

Embodiment 1

[0033] Put 1g of P123 in a flat-necked flask filled with 40mL of 1mol / L HCl, then add 3g of HAc, then put the flat-necked flask in a water bath at 30°C and stir for 3 hours to dissolve P123; then add 6.24g of TEOS, Stir for 24 hours; take out the white suspension, filter it with suction and wash it with deionized water three times, then transfer it to 60mL of deionized water dissolved with 2.47g of ammonium molybdate, then add ammonia water dropwise to adjust the pH value to 0, and pre- After hydrolysis for 2 hours, pour the solution into a 100mL autoclave lined with polytetrafluoroethylene, and conduct a hydrothermal treatment at 110°C for 12 hours; suction-filter and wash the gel sample in the kettle for 3 times, and then dry it at room temperature. Calcined at 550°C for 5h to obtain the final Mo-SBA-15 sample. Take 5g of 20-40mesh sample, and then prepare a nickel nitrate solution containing 0.7g of nickel nitrate, add it dropwise to Mo-SBA-15 to make it soak, leave it at r...

Embodiment 2

[0035] Put 2g of P123 in a flat-necked flask filled with 50mL of 1mol / L HCl, then add 3.2g of HAc, then put the flat-necked flask in a water bath at 35°C and stir for 3 hours to dissolve P123; then add 3g of TEOS, Stir for 24 hours; take out the white suspension, filter it with suction and wash it with deionized water three times, transfer it to 60mL deionized water dissolved with 2.47g ammonium molybdate, then add ammonia water dropwise to adjust the pH value to 0.2, and pre- After hydrolysis for 2 hours, pour the solution into a 100mL autoclave lined with polytetrafluoroethylene, and conduct a hydrothermal treatment at 130°C for 15 hours; suction filter and wash the gel sample in the kettle for 3 times, and then dry it at room temperature. Calcined at 550°C for 5h to obtain the final Mo-SBA-15 sample. Take 5g of a sample of 20-40 mesh, and then prepare a nickel nitrate solution containing 0.7g of nickel nitrate, add it dropwise to Mo-SBA-15 to make it soak, leave it at room ...

Embodiment 3

[0037] Put 3g of P123 in a flat-necked flask filled with 60mL of HCl with a concentration of 1.5mol / L, then add 3.8g of HAc, then put the flat-necked flask in a water bath at 38°C and stir for 3 hours to dissolve P123; then add 4g of TEOS, Stir in the middle for 24 hours; take out the white suspension, filter it with suction and wash it with deionized water three times, transfer it to 60mL deionized water dissolved with 2.47g ammonium molybdate, then add ammonia water dropwise to adjust the pH value to 0.4, at 38°C After pre-hydrolysis for 2 hours, pour the solution into a 100mL autoclave lined with polytetrafluoroethylene, and conduct a hydrothermal treatment at 150°C for 18 hours; suction-filter and wash the gel-like sample in the kettle for 3 times, and then dry it at room temperature , and fired at 550°C for 5h to obtain the final Mo-SBA-15 sample. Take 5g of a sample of 20-40 mesh, and then prepare a nickel nitrate solution containing 0.7g of nickel nitrate, add it dropwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com