Automatic overturning mechanism for welding fixture

An automatic flipping and welding fixture technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult equipment cleaning and maintenance, expensive manipulators, and poor running stability, so as to save production energy consumption, Takes up little space and ensures stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

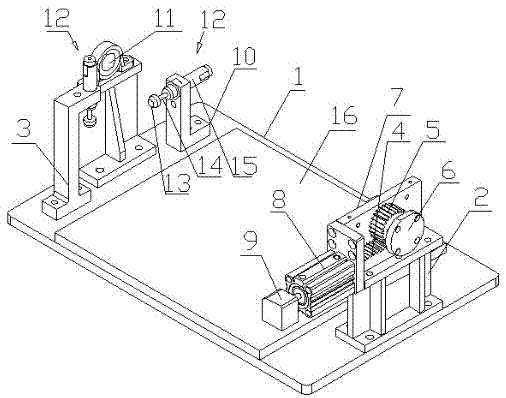

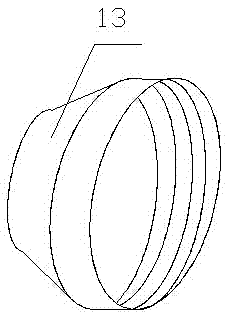

[0014] During installation, at first a moisture-proof pad 16 is set on the workbench 1, and a driving shaft mounting frame 2 and a driven shaft mounting frame 3 are arranged on both sides of the moisture-proof pad 16, and a rack 4 is arranged on the driving shaft mounting frame 2, and the rack 4 and the gear 5 meshing, the drive shaft bushing 6 is set on the gear 5, the assembly plate 7 is set on the outside of the rack 4, one end of the rack 4 is connected to one end of the nitrogen cylinder 8, and the other end of the nitrogen cylinder 8 is connected to the solenoid valve 9, from Driven shaft mounting frame 3 is provided with driven shaft shaft sleeve 3, and one side of driven shaft mounting frame 3 is provided with buffer device mounting frame 10, buffer device mounting frame 10, driving shaft mounting frame 2, driven shaft mounting frame 3 are all A buffer device 12 is provided. The buffer device 12 is composed of a metal contact 13, a compression rod 14 and a nitrogen cyli...

Embodiment 2

[0016] When in use, the electromagnetic valve 9 is activated by the PLC controller, the nitrogen cylinder 8 pushes the rack 4, and the rack 4 drives the gear 5 meshing with the rack 4 to rotate during the movement, and the gear 5 is provided with a driving shaft sleeve 6 to drive The shaft sleeve 6 is connected with the welding jig through a bearing, that is, the rotation of the gear 5 drives the jig to rotate, and the workpiece contacts the metal contact 13 when rotating, and the metal contact 13 pushes the telescopic rod 14, and the telescopic rod 14 moves in the nitrogen cylinder 15 to Buffer the inertial force of the workpiece rotation to avoid bumping or shaking, and the metal contact 13 is provided with threads inside, the metal contact 13 is connected to the telescopic rod 14 through the thread, and can be disassembled when the appearance of the metal contact is damaged. replace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com