Preparation method of three-dimensional network-shaped tungsten carbide-carbon nanotube composite material

A carbon nanotube and composite material technology is applied in the field of preparation of three-dimensional network tungsten carbide-carbon nanotube composite materials, which can solve the problems of easy agglomeration and low catalytic activity of methanol, so as to improve electrical conductivity, reduce reaction time, improve The effect of electrocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Weigh 0.2g WCl in the glove box 6 , dissolved in 20mL of absolute ethanol, stirred evenly and placed in the InitiatorEXP microwave synthesizer, the reaction pressure of the microwave reaction was 15bar, and the reaction was carried out at 160°C for 1h. After the reaction was completed, it was cooled to room temperature, washed with deionized water and absolute ethanol for 3 times, and dried in a vacuum oven at 50°C for 6 hours.

[0040] 2. Put the dried sample above into a tube furnace, calcinate at 700°C for 3 hours in a CO atmosphere of 100mL / min, and then cool to room temperature under a nitrogen protective atmosphere to obtain WC-CNTs particles, which are marked as WC-CNTs- 700.

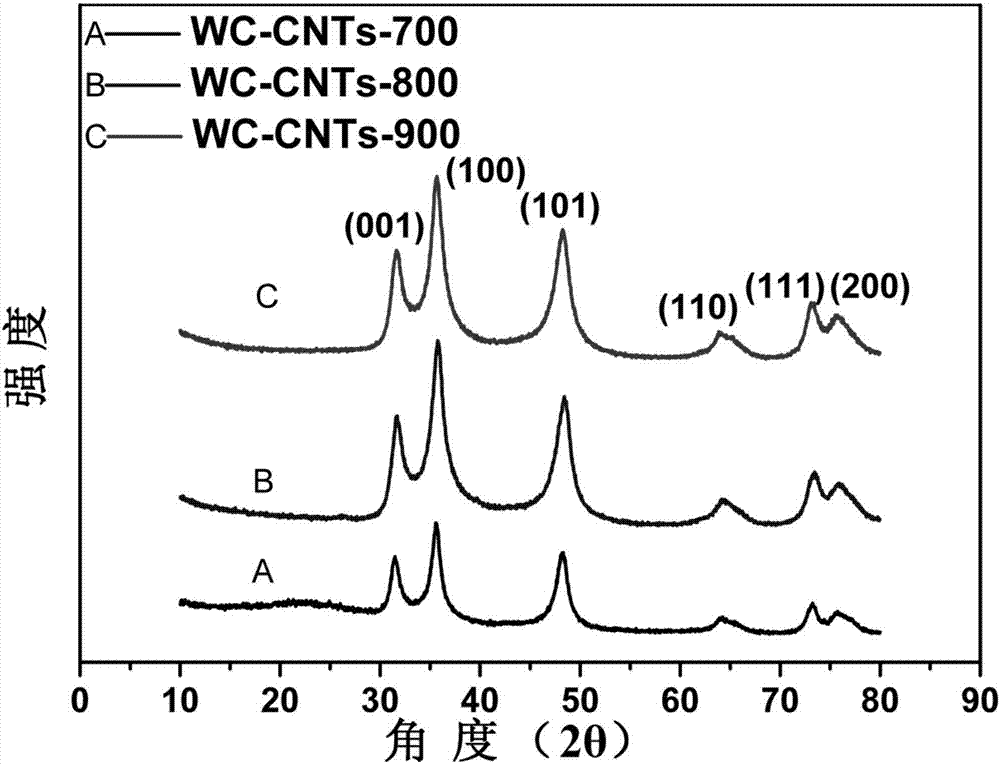

[0041] Depend on figure 1In the XRD pattern of WC-CNTs-700 shown in A, it can be concluded that the diffraction peaks at 2θ diffraction angle positions of 31.5°, 35.6°, 48.3°, 64.0°, 73.1°, and 75.5° belong to WC ( 001), (100), (101), (110), (111), (200) crystal faces (01-072-0097). ...

Embodiment 2

[0044] 1. Weigh 0.2g WCl in the glove box 6 , dissolved in 20mL of absolute ethanol, stirred evenly and placed in the InitiatorEXP microwave synthesizer, the reaction pressure of the microwave reaction was 15bar, and the reaction was carried out at 160°C for 1 hour. After the reaction was completed, it was cooled to room temperature, washed with deionized water and absolute ethanol for 3 times, and dried in a vacuum oven at 50°C for 6 hours.

[0045] 2. Put the dried sample above into a tube furnace, calcinate at 800°C for 3 hours in a CO atmosphere of 100mL / min, and then cool to room temperature under a nitrogen protective atmosphere to obtain WC-CNTs particles with carbon nanotubes grown. Marked as WC-CNTs-800.

[0046] Depend on figure 1 In the XRD pattern of WC-CNTs-800 shown in B, it can be concluded that the diffraction peaks at 2θ diffraction angle positions of 31.5°, 35.6°, 48.3°, 64.0°, 73.1°, and 75.5° belong to WC ( 001), (100), (101), (110), (111), (200) crystal...

Embodiment 3

[0049] 1. Weigh 0.2g WCl in the glove box 6 , dissolved in 20mL of absolute ethanol, stirred evenly and placed in the InitiatorEXP microwave synthesizer, the reaction pressure of the microwave reaction was 15bar, and the reaction was carried out at 160°C for 1h. After the reaction was completed, it was cooled to room temperature, washed with deionized water and absolute ethanol for 3 times, and dried in a vacuum oven at 50°C for 6 hours.

[0050] 2. Put the above-mentioned dried sample into a tube furnace, calcinate at 900°C for 3 hours under 100mL / min CO atmosphere, and then cool to room temperature under a nitrogen protective atmosphere to obtain WC particles with grown carbon nanotubes. Marked as WC-CNTs-900.

[0051] Depend on figure 1 In the XRD pattern of WC-CNTs-900 shown in C, it can be concluded that the diffraction peaks at 2θ diffraction angle positions of 31.5°, 35.6°, 48.3°, 64.0°, 73.1°, and 75.5° belong to WC ( 001), (100), (101), (110), (111), (200) crystal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com