Oil-well cement temperature-sensitive slow-release coagulation accelerator

A technology of oil well cement and temperature sensitivity, which is applied in the field of cement slurry, which can solve the problems of increased construction period and long waiting time for setting, and achieves the effects of cost saving, low cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A temperature-sensitive slow-release coagulant for oil well cement, the preparation process is as follows:

[0019] Add 5 parts by weight of stearic acid and 100 parts by weight of absolute ethanol into the conical flask, stir thoroughly, heat in a water bath at 75°C until the stearic acid is fully dissolved, then add 1.5 parts by weight of polyethylene glycol 4000, and 1.5 parts by weight of calcium chloride , stop stirring after 3 minutes, ultrasonically oscillate for 20 minutes, so that polyethylene glycol 4000 and calcium chloride are evenly dispersed in the solution, restart stirring while cooling down to below 35°C, filter, and dry at room temperature for 24 hours.

Embodiment 2

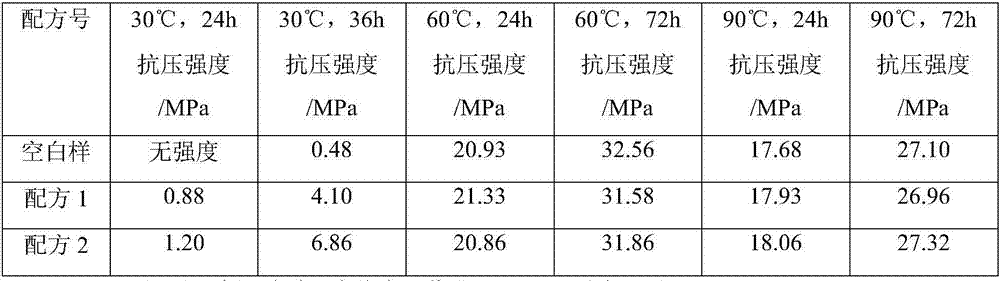

[0021] (1) Cement slurry configuration and performance test

[0022] According to the current standard for the preparation of oil well cement slurry - GB / T19139-2012 "Test Methods for Oil Well Cement", the low-density cement slurry with floating beads was prepared, and its conventional engineering performance was tested. The results are shown in Table 1.

[0023] Blank sample: 100 parts of oil well cement, 25 parts of 3M floating beads, 25 parts of micro silicon, 5 parts of fluid loss reducer (2-acrylamide-2-methylpropanesulfonic acid), 3 parts of retarder (lignosulfonic acid Sodium), mix and stir evenly to obtain the dry-mixed material; 1 part of dispersant (sodium polystyrene sulfonate), 0.2 part of defoamer (simethicone) is dissolved in 44 parts of water and stirred evenly, to obtain the wet-mixed material ; Under the stirring condition of 4000 rpm / min, the dry mix material was added to the wet mix material at a uniform speed (15s), then stirred at 12000 rpm for 35s and def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com