Integrated electrochemical reaction apparatus for processing difficultly degraded organic waste water and processing method thereof

A technology for organic wastewater treatment and chemical reaction, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., which can solve the problems of single treatment of pollutants, limited use, low current efficiency and utilization rate, etc. , to achieve the effect of speeding up the reaction process, increasing the rate and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

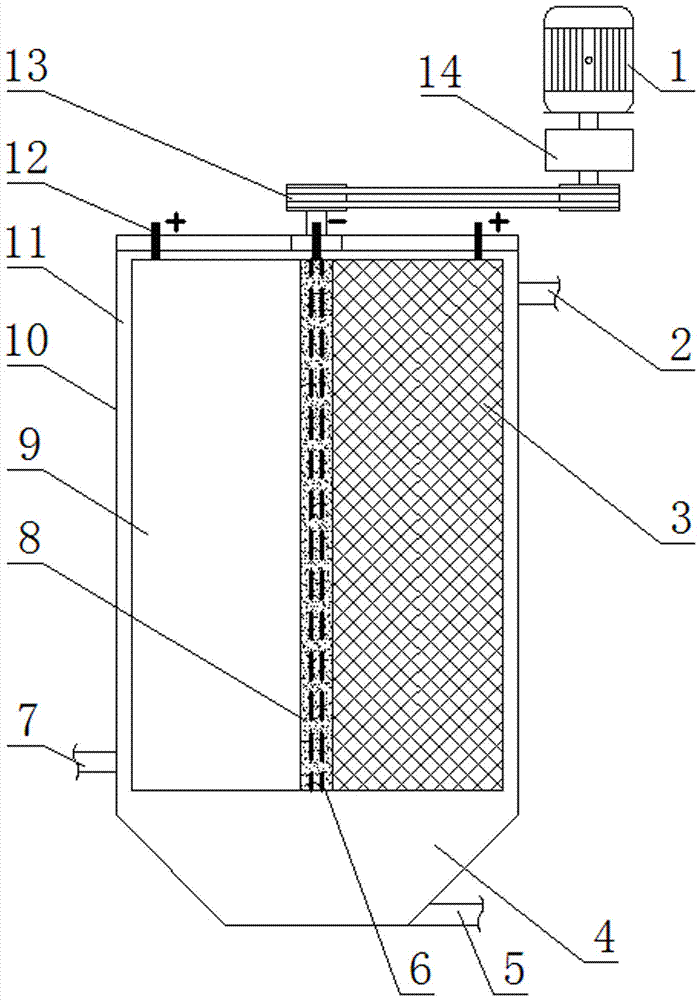

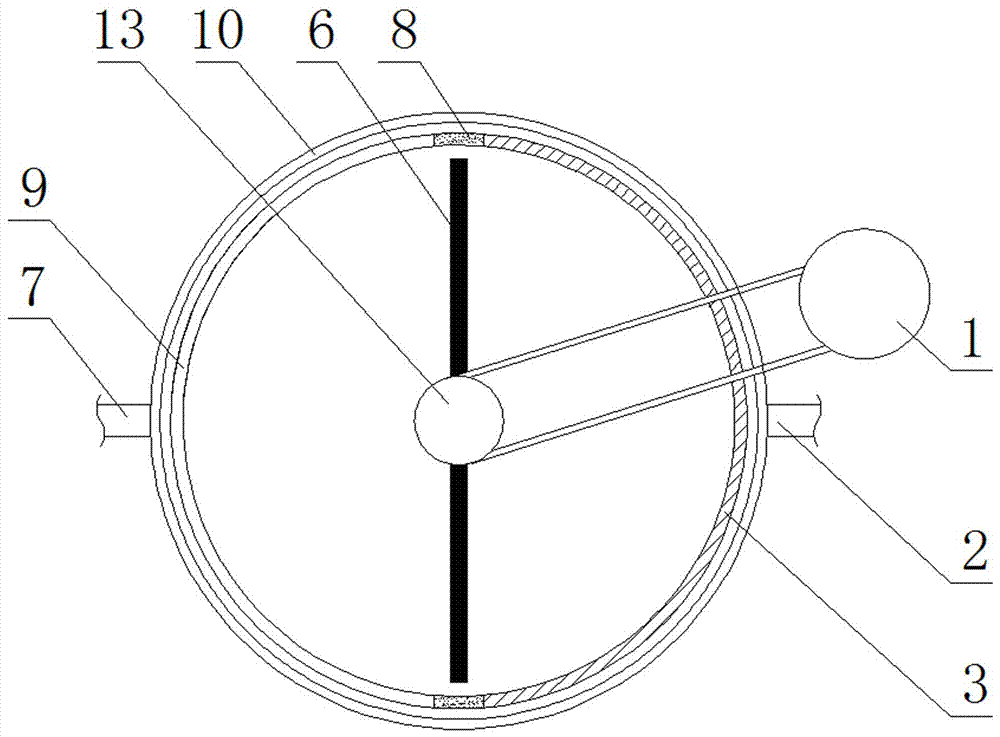

[0039]Inject refractory organic wastewater into the reactor housing 10 through the water inlet pipe 2; turn on the stabilized power supply 11 and start the motor 1, the current is 5A, the output speed of the motor 1 through the reducer 14 is 1.5 rpm, and the stainless steel cathode 6 Driven by the motor 1, it rotates slowly, and the wastewater is slowly stirred, so as to increase the molecular collision in the reaction process and improve the reaction efficiency; wherein, near the semi-arc ruthenium iridium anode 9, electricity occurs in the chlorine-containing wastewater The oxidation process can effectively remove the ammonia nitrogen in the waste water, and the hypochlorous acid oxidant produced can also disinfect the waste water. At the same time, the produced nitrogen gas has no secondary pollution; the semi-arc porous iron mesh 3 is used as the anode in parallel, and the external power supply Under the action, the iron mesh dissolves and flocculates with the hydroxide ion...

Embodiment 2

[0041] According to the operation steps of Example 1, the wastewater in the reactor shell 10 comes from the leachate of an aging landfill. The leachate of the aged landfill is highly polluting, the water quality fluctuates for a long time, and its biodegradability is poor. The integrated electrochemical reaction device can be used as treatment equipment in the pretreatment process to remove some pollutants in the wastewater, improve the biodegradability of the wastewater, and facilitate subsequent biochemical treatment. The current of the reaction device is 5A, and the residence time of waste liquid is 5h. The measured average influent COD, ammonia nitrogen and TP concentrations are 3000, 240 and 30mg / L respectively. Under the action of various mechanisms, the average effluent COD, ammonia nitrogen and The TP concentrations were 468, 47, and 3.2 mg / L, respectively, and the removal rates of COD, ammonia nitrogen, and TP in the reactor were 84%, 80%, and 88%, respectively, and th...

Embodiment 3

[0043] According to the operation steps of Example 1, the influent of the wastewater into the reactor shell 10 comes from the wastewater discharged from a coking plant. Toxic and refractory organic pollutants such as phenols, pyridine, and quinoline. This integrated electrochemical reaction device is used to treat coking wastewater. The influent is COD 3500mg / L, of which volatile phenol is 640mg / L and ammonia nitrogen is 280mg / L. Set the reaction current to 5A and the residence time to 8h. After the reactor, the average effluent COD is 600mg / L, the volatile phenol content is reduced to 28mg / L, and the ammonia nitrogen concentration is 21mg / L. The yellow-black sediment produced in the reaction process is discharged from the mud discharge pipe 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com