A kind of ultra-thin mixed crystal titanium dioxide nanosheet and its preparation method and application

A technology of titanium dioxide and nanosheets, which is applied in the field of ultra-thin mixed crystal titanium dioxide nanosheets and its preparation, can solve the problems of scarcity of preparation and performance research, lack of research on morphology and performance, etc., and is conducive to large-scale promotion and use. Efficient reaction stability, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

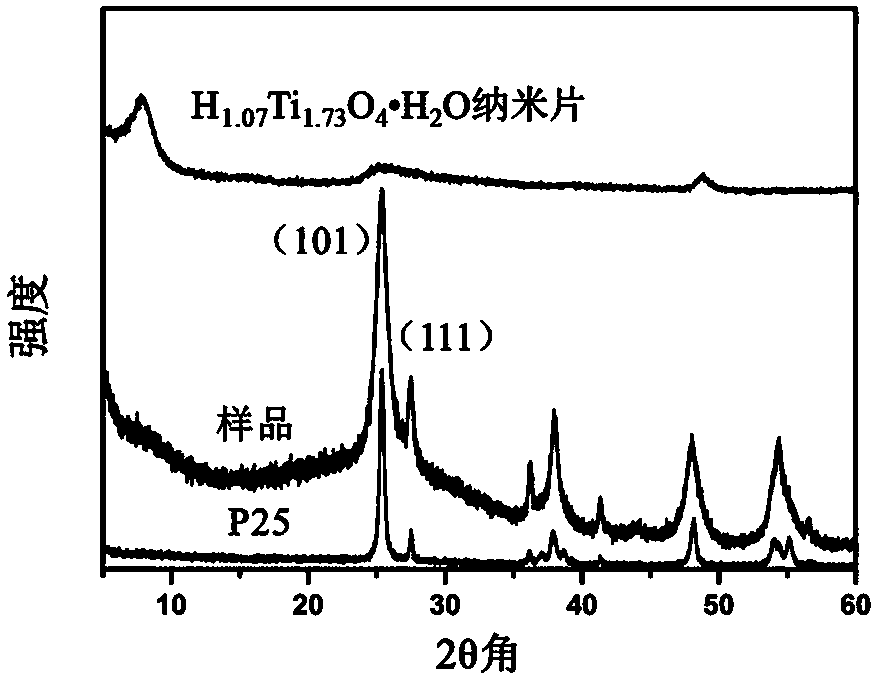

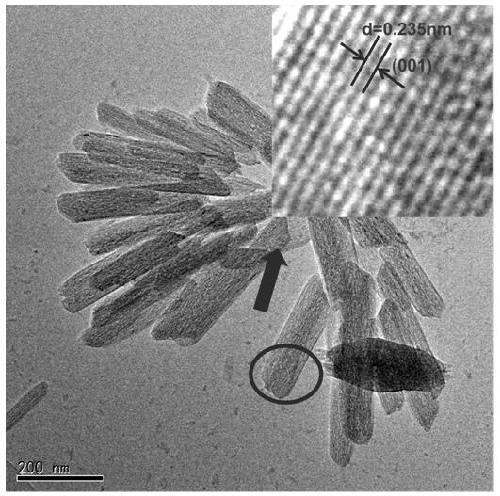

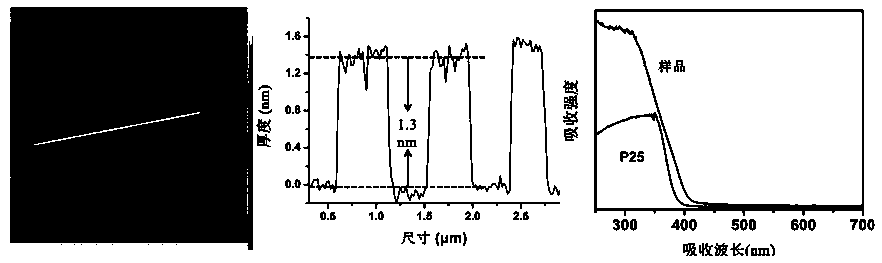

[0025] Ultra-thin H 1.07 Ti 1.73 o 4 ·H 2 Preparation of O nanosheet precursors

[0026] Will K 2 CO 3 , Li 2 CO 3 and TiO 2 After grinding evenly according to the mass ratio of 1:13:3, put it in a corundum crucible, calcined at 800 °C for 2 h, cooled to room temperature, ground again, calcined at 1000 °C for 20 h, and repeated once; to obtain layered K 0.80 Ti 1.73 Li 0.67 o 4 compound, the resulting K 0.80 Ti 1.73 Li 0.67 o 4 The sample was added to 1000 ml of hydrochloric acid solution (1 mol / L) and stirred, and the acid was changed every 24 h. After four cycles, the product was centrifuged, and then the product was washed with deionized water until it was neutral, and dried at 60 °C. Layered H 1.07 Ti 1.73 o 4 ·H 2 O; the above layered H 1.07 Ti 1.73 o 4 •H 2 O was mixed with TBAOH (tetrabutylammonium hydroxide) (40 wt%) solution at a molar ratio of 1:1, magnetically stirred for 15 days, centrifuged at 3000 rpm, and the unstripped layer was removed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com