Super-hydrophobic super-oleophilic filter membrane, and preparation method and applications thereof

A super-oleophilic and super-hydrophobic technology, applied in separation methods, chemical instruments and methods, membranes, etc., can solve the problems of unsuitable oil-water emulsion separation, high cost of recovery of distilled oil, and long separation time, so as to facilitate large-scale production , The method is simple, and the effect of speeding up the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation of embodiment 1 superhydrophobic superoleophilic filtration membrane

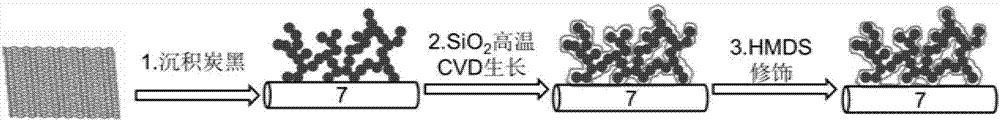

[0043] figure 1 It is a schematic diagram of the preparation process of the superhydrophobic and superoleophilic filtration membrane of the present invention, and its specific operation steps are as follows:

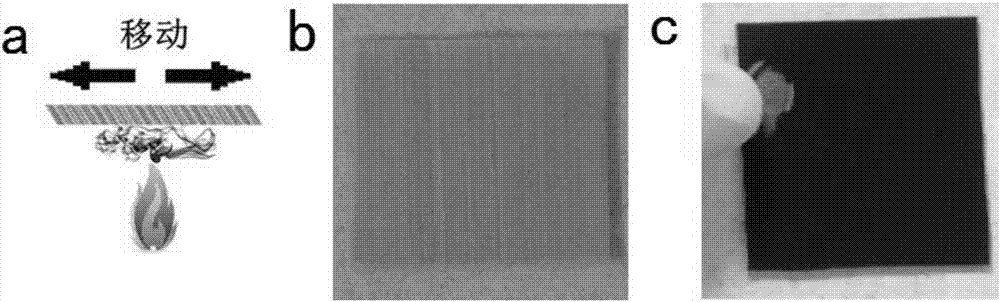

[0044] Use a copper mesh as a porous mesh substrate, place it over a flame to bake the carbon black, and stop baking when the surface of the copper mesh is completely black. see figure 2 , figure 2 a is a schematic diagram of baking carbon black, figure 2 b is the photo of the copper mesh of unbaked carbon black, figure 2 c is a photo of the copper mesh after baking carbon black; it can be seen from the figure that after baking carbon black, the copper mesh turns black, but the carbon black can be separated from the copper mesh by lightly touching it with your fingers ( figure 2 c).

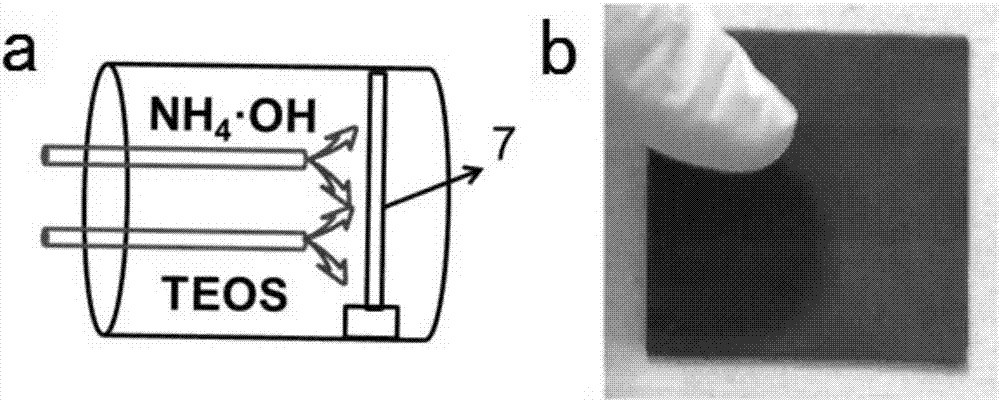

[0045] Then the copper grid with the deposited carbon black film was placed in a che...

Embodiment 2

[0048] Embodiment 2 tubular oil-water separation method

[0049] The super-hydrophobic and super-oleophilic filtration membrane prepared in embodiment 1 is rolled into a tubular shape (such as Figure 6 As shown), a separation tube with a length of 10 cm was prepared, and the two ends of the separation tube were respectively connected with two rubber tubes, placed horizontally on the test tube rack, and then the oil-water mixture was directly transported through the separation tube from one end, and the Fast and efficient oil-water separation. The oil seeps out quickly from the separation tube and flows into the collector below, while the water flows out from the rubber tube at the other end, which completely solves the problem of water resistance caused by specific gravity when the traditional flat membrane is separated from top to bottom. Tests have proved that the separation efficiency of the super-hydrophobic and super-oleophilic filtration membrane prepared by the presen...

Embodiment 3

[0051] Embodiment 3 Tube type oil-water separator

[0052] According to the method provided by the invention, a tubular oil-water separator can be prepared to realize industrial oil-water separation. Such as Figure 8 As shown, the oil-water separator includes an S-shaped spiral oil-water separation pipeline 1, a water pump 2, a sewage inlet 3, a drain pipe 4 and an oil sump 5. The material of the oil-water separation pipeline 1 is a super-hydrophobic super-oleophilic filter membrane. One end of the oil-water separation pipeline 1 is connected with a pump 2, which is used to extract oily sewage from the outside, and then the oily sewage enters the oil-water separation pipeline 1 through the sewage inlet 3. Due to the effect of its super-hydrophobic and super-oleophilic filter membrane, the oil droplets 6 seep out from the pipeline and flow into the oil collection tank 5 below, and the separated water flows out from the drain pipe 4 to achieve the effect of oil-water separatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com