Honeycomb thermal insulation mortar as well as manufacturing method and application thereof

A thermal insulation mortar and honeycomb technology, which is applied in the field of building thermal insulation materials, can solve problems affecting the popularization and application of thermal insulation mortar, increase the thickness of the external wall insulation layer, and increase the cost of the project, so as to increase the fireproof package area, enhance the thermal insulation effect, and reduce the cost of the project. The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

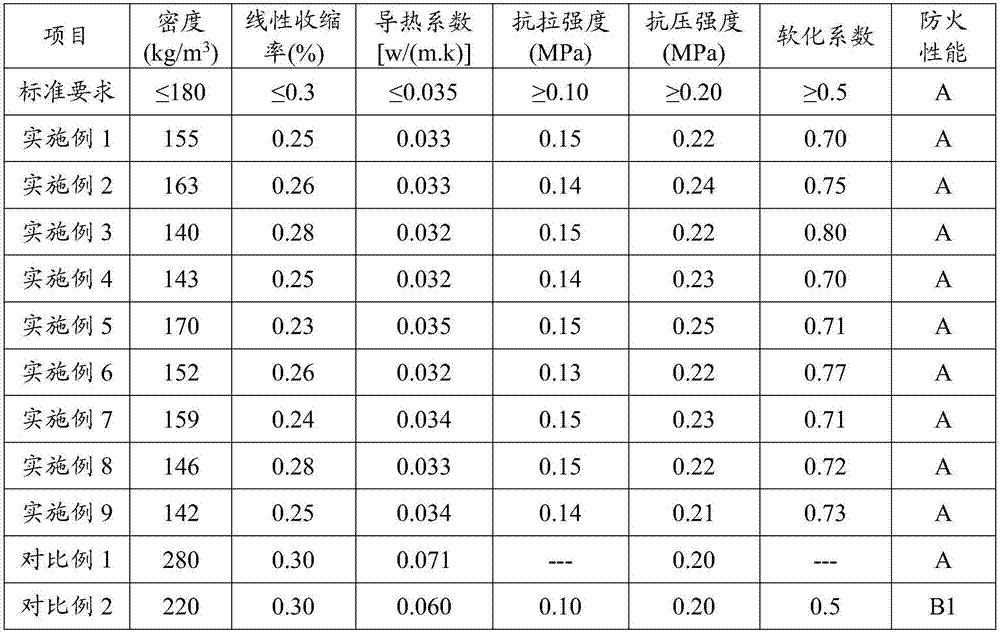

Examples

Embodiment 1

[0071] As described in this embodiment, a honeycomb thermal insulation mortar, the raw material formula is measured in parts by weight, and includes the following components:

[0072] Silica powder: 120 parts;

[0073] Silica airgel: 5 parts;

[0074] Polystyrene particles: 14 parts;

[0075] Dispersible latex powder: 4.85 parts;

[0076] Cellulose hydroxypropyl methyl ether: 0.15 parts;

[0077] Foaming agent: 3 parts.

[0078] Described in this embodiment, the particle size is 325 mesh silicon micropowder as an example for illustration;

[0079] Described in the present embodiment, adopt particle size to be that 400 order dispersible latex powders are taken as an example to illustrate;

[0080] As described in this embodiment, cellulose hydroxypropyl methyl ether with a particle size of 400 mesh is used as an example for illustration;

[0081] As described in the present embodiment, the foaming agent with a particle size of 200 mesh is used as an example for illustrati...

Embodiment 2

[0088] This embodiment is improved on the basis of Embodiment 1, and the content described in Embodiment 1 is also included in this embodiment, and will not be described in detail here.

[0089] As described in this embodiment, a honeycomb thermal insulation mortar, the raw material formula is measured in parts by weight, and includes the following components:

[0090] Silica powder: 128 parts;

[0091] Silica airgel: 5.8 parts;

[0092] Polystyrene particles: 14 parts;

[0093] Dispersible latex powder: 5 parts;

[0094] Cellulose hydroxypropyl methyl ether: 0.16 parts;

[0095] Foaming agent: 3.4 parts.

[0096] As described in this embodiment, a method for manufacturing honeycomb thermal insulation mortar comprises the following steps:

[0097] 128 parts of the microsilica powder, 5.8 parts of the silica airgel, 14 parts of the polyphenylene particles, 5 parts of the dispersible latex powder, 0.16 parts of the cellulose hydroxypropyl methyl ether and the 3.4 parts of ...

Embodiment 3

[0100] This embodiment is improved on the basis of Embodiment 1, and the content described in Embodiment 1 is also included in this embodiment, and will not be described in detail here.

[0101] As described in this embodiment, a honeycomb thermal insulation mortar, the raw material formula is measured in parts by weight, and includes the following components:

[0102] Silica powder: 110 parts;

[0103] Silica airgel: 5 parts;

[0104] Polystyrene particles: 13 parts;

[0105] Dispersible latex powder: 5.8 parts;

[0106] Cellulose hydroxypropyl methyl ether: 0.18 parts;

[0107] Foaming agent: 3.5 parts.

[0108] As described in this embodiment, a method for manufacturing honeycomb thermal insulation mortar comprises the following steps:

[0109] 110 parts of the microsilica powder, 5 parts of the silica airgel, 13 parts of the polyphenylene particles, 5.8 parts of the dispersible latex powder, 0.18 parts of the cellulose hydroxypropyl methyl ether and the 3.5 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com