A kind of preparation technology of highly emulsifying egg yolk powder

A preparation process, the technology of egg yolk powder, which is applied in the field of preparation process of highly emulsifying egg yolk powder, can solve the problems of reduced emulsifying performance, reduced emulsifying thermal stability, low emulsifying performance, etc., to reduce the loss of nutrients, Achieve production efficiency and improve emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

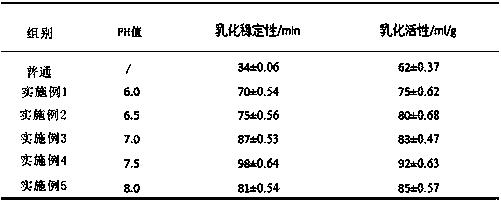

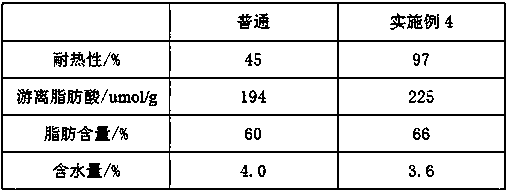

Embodiment 1

[0025] The egg yolk powder preparation of embodiment 1 comprises the following steps:

[0026] 1) Fresh eggs are selected as raw materials, and the eggshell is required to be complete, the surface is clean and dull, and a slight quicklime smell can be smelled by breathing gently on the eggshell. Soak fresh eggs in clean water for 8 minutes, take them out, and then soak them in a bleach solution with an available chlorine content of 1100mg / kg for 8 minutes to remove floating dust, chicken manure and other impurities on the eggshells, take them out of the bleach solution and dry them in a drying oven Finally, gently open the eggs, separate the egg whites and egg yolks, and put the egg yolks into containers for later use;

[0027] 2) Stir the egg yolk part prepared in step 1), so that the egg yolk membrane is broken to release the egg yolk liquid, and the egg yolk liquid is homogenized. During the stirring process, the stirring speed should be slow and the stirring time should be...

Embodiment 2

[0034] The egg yolk powder preparation process in Example 2 is the same as in Example 1, except that in step 4), citric acid or sodium carbonate solution is used to adjust the pH value of the sugar-free egg yolk liquid dilution to 6.5.

Embodiment 3

[0035] The preparation process of egg yolk powder in Example 3 is the same as in Example 1, except that in step 4), citric acid or sodium carbonate solution is used to adjust the pH value of the sugar-free egg yolk liquid dilution to 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com