Positive pole active material cladding liquid, preparation method thereof, and cladding method for positive pole active material

A positive electrode active material and coating technology, which is applied in the field of positive electrode active material coating, can solve the problems of poor cycle performance of lithium-ion batteries and uneven coating of aluminum phosphate, so as to improve thermal stability and maintain battery capacity Performance, the effect of avoiding side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

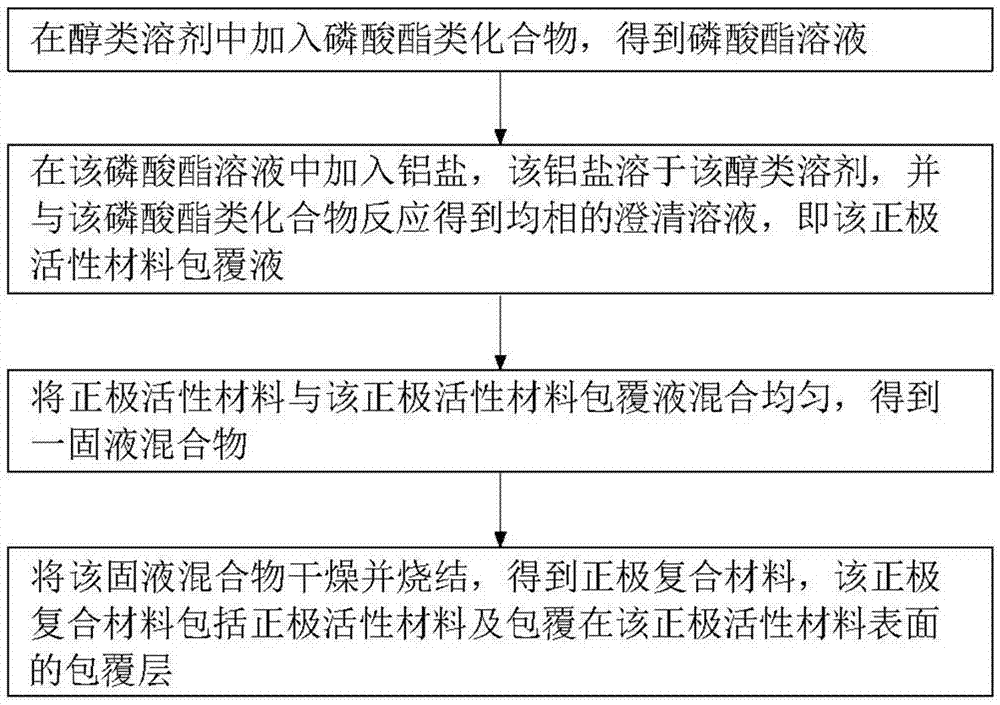

[0032] See figure 1 The embodiment of the present invention further provides a method for preparing the above-mentioned cathode active material coating solution, and the method includes the following steps:

[0033] S1, adding a phosphate compound to the alcohol solvent to obtain a phosphate solution; and

[0034] S2: Add aluminum salt to the phosphoric acid ester solution, the aluminum salt is dissolved in the alcohol solvent, and reacts with the phosphoric acid ester compound to obtain a homogeneous clear solution, that is, the positive electrode active material coating solution.

[0035] The alcohol solvent is preferably one or more composite solvents of methanol, ethanol, propanol, n-butanol and isopropanol.

[0036] The general formula of the phosphate compound can be A n P(O)(OH) m , Where A is the carbonoxy group corresponding to the alcohol solvent molecule, such as at least one of methoxy, ethoxy, propoxy, butoxy and isopropoxy, n=1~3, m=0~2, m+n=3. The phosphate compounds c...

Embodiment 1

[0061] Mix phosphorus pentoxide and ethanol in a molar ratio of 1:10, stir at room temperature to completely react the phosphorus pentoxide to form a phosphate solution; mix aluminum nitrate and ethanol in a molar ratio of 1:10 to make aluminum nitrate Dissolve completely to produce aluminum nitrate solution. The molar ratio of P:Al in the phosphorus pentoxide to aluminum nitrate is 1:1; mix the phosphate ester solution with the aluminum nitrate solution, and stir the reaction at 50°C to obtain a homogeneous and clear positive electrode Active material coating liquid.

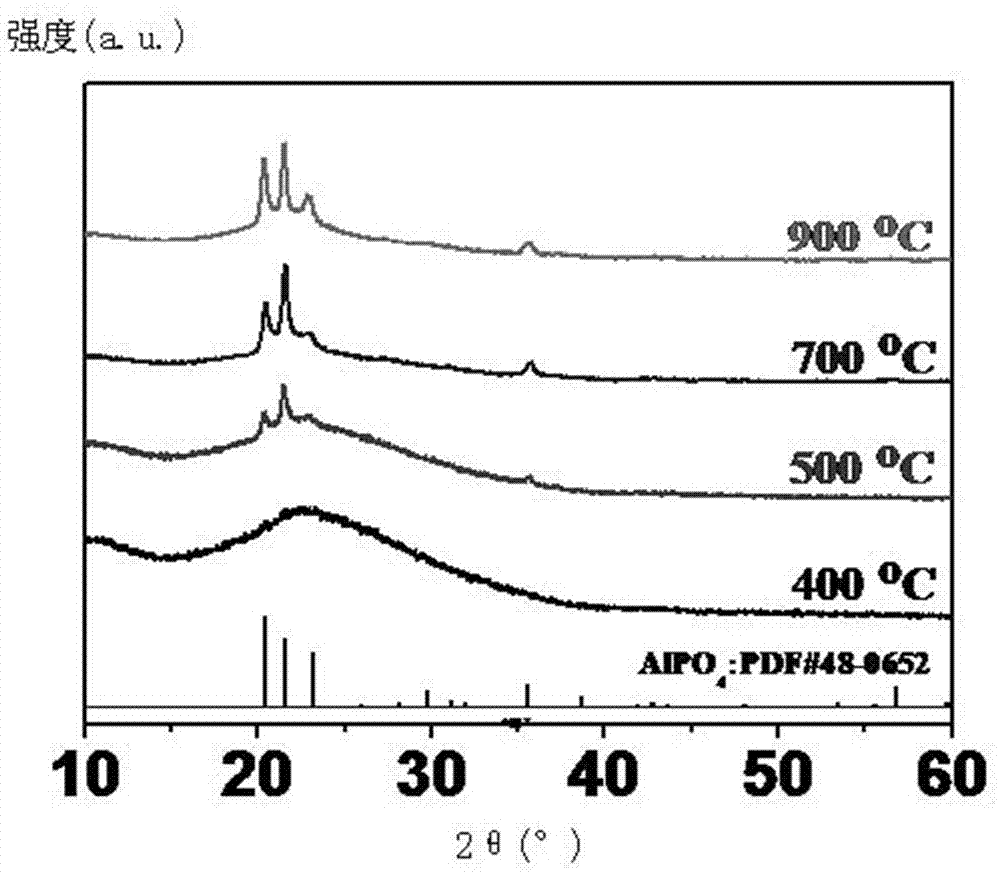

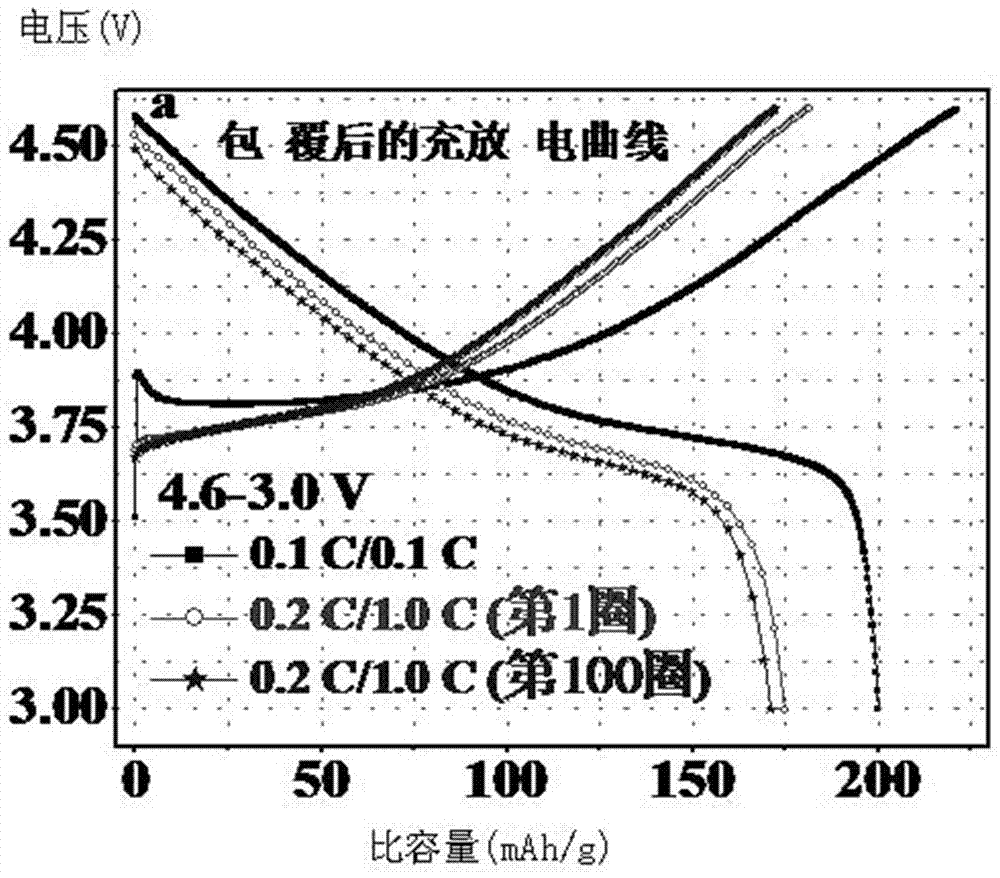

[0062] The positive electrode active material coating solution and the positive electrode active material LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 Mix according to the mass ratio of 1:5~1:2, filter the excess liquid phase, dry at 60°C and sinter in 400°C air to obtain the positive electrode composite material and assemble the lithium ion battery. The electrolyte in this lithium ion battery is 1.0 mol L -1 LiPF 6 (EC / EMC=3:7, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com