Handheld automatic lifting pile driving (well digging) and pile pulling all-in-one machine

An automatic lifting and all-in-one technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of life-threatening, occupying a lot of manpower, and difficulty in standing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] (Note: The air pump used as the air source is prepared separately and will not be described here)

[0020] Now use an example to illustrate the specific implementation method, the outsourced steam hammer vibrator kit (including a full set of control valves, air pipes, quick-change joints, etc.), all clamping cylinder kits, all jacking cylinder kits, screws and oil nozzles spare.

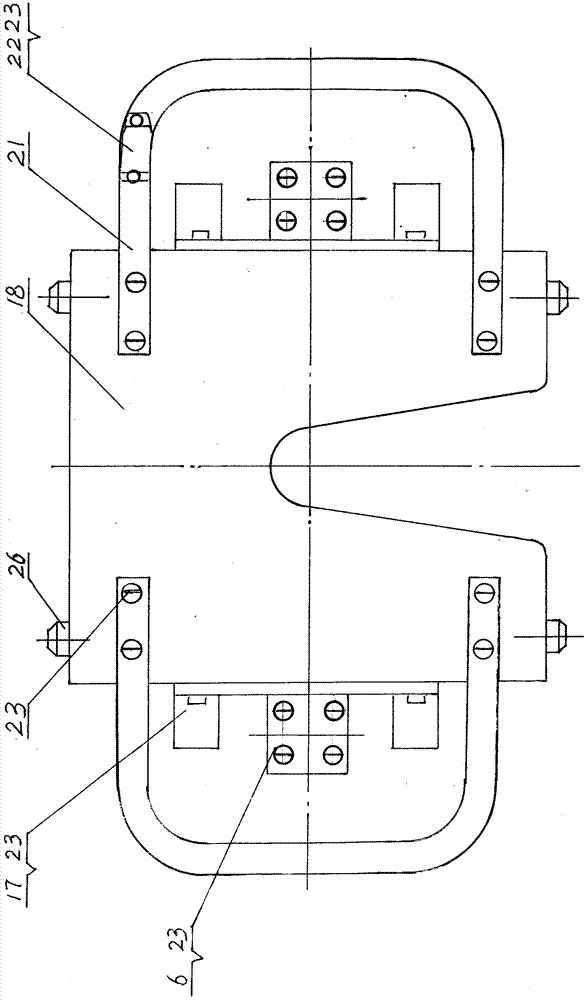

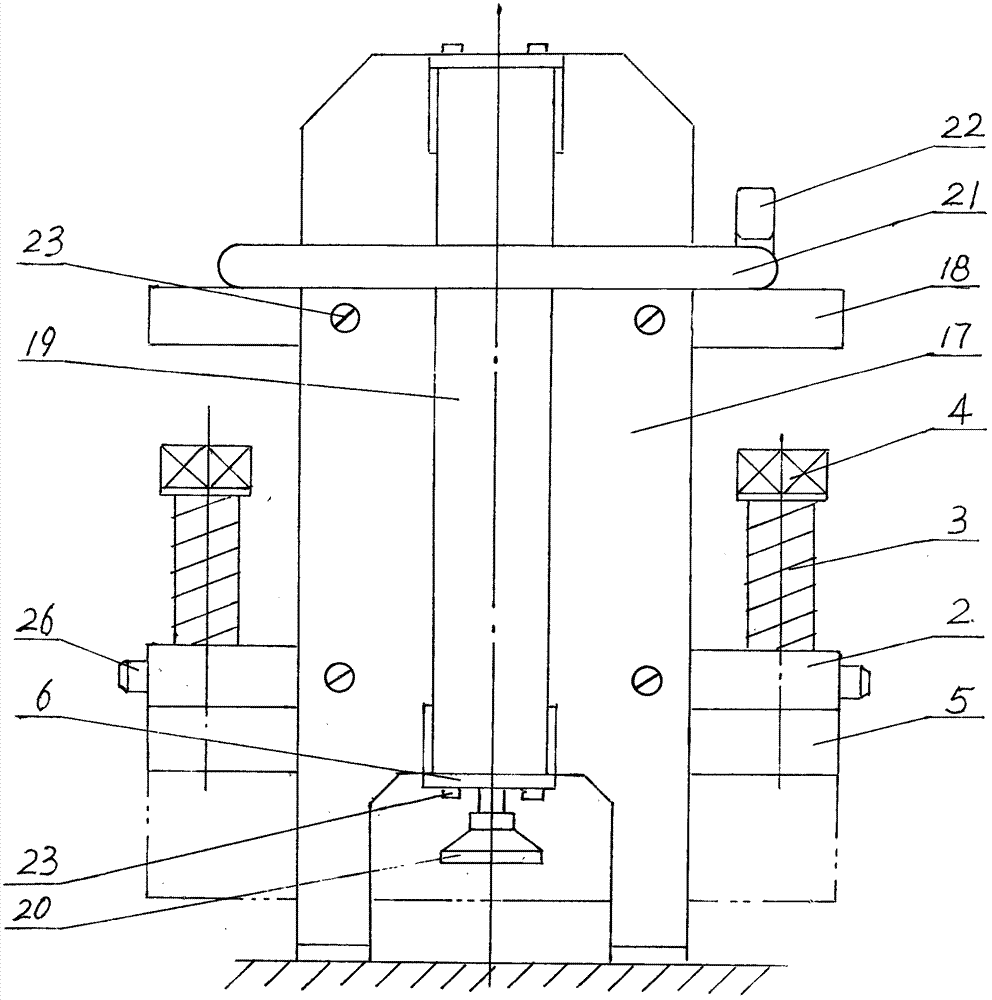

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the top plate (18), bottom plate (2), clamping plate (5), upper guide plate (9), lower guide plate (10), upper positioning block (12), lower Positioning block (13), adjusting screw sleeve (14) and jacking pad (20), the handle (21) is made of steel pipe, the foot plate (17) is made of steel plate, and the brake clamping block is made of alloy steel forging through machining (8) and fixed clamping block (11), after hardening, make concave tooth-like transverse bar-shaped protrusions with EDM process, and adjust screw rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com