A kind of weather-resistant hot-melt pressure-sensitive adhesive and preparation method thereof

A hot-melt, pressure-sensitive adhesive technology, used in adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problem of hot-melt pressure-sensitive adhesives being prone to aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A weather-resistant hot-melt pressure-sensitive adhesive is composed of the following raw materials by mass percentage: 80% of butyl rubber, 0.5% of hydroxy acrylic resin, 10% of tackifier, 5% of plasticizer, 0.5% of silane coupling agent, Antioxidant 2% and UV Resistant 2%.

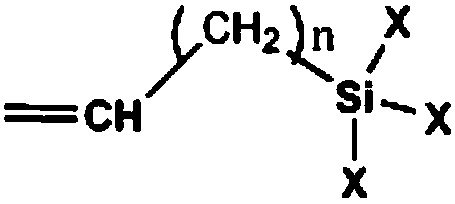

[0032] The unsaturation degree of the butyl rubber is 0.5%; the hydroxyl value of the hydroxy acrylic resin is 100; the silane coupling agent is allyl triethoxysilane; the tackifier is C5 Petroleum resin; the plasticizer is polyisobutylene; the molecular weight of the polyisobutylene is less than 3000; the antioxidant is SK1010; the UV-resistant agent is compounded by UV-531 and UV-327, The mass ratio of the two is 1:2.

[0033] The present invention also provides a method for preparing the weather-resistant hot-melt pressure-sensitive adhesive, comprising the following steps:

[0034] (1) Put butyl rubber, plasticizer, tackifier, hydroxy acrylic resin, silane coupling agent into a reactor with ...

Embodiment 2

[0039] A weather-resistant hot-melt pressure-sensitive adhesive is composed of the following raw materials by mass percentage: 56% of butyl rubber, 5% of hydroxy acrylic resin, 20% of tackifier, 12% of plasticizer, 3% of silane coupling agent, Antioxidant 2% and UV Resistant 2%.

[0040] The unsaturation degree of the butyl rubber is 2.0%; the hydroxyl value of the hydroxyacrylic resin is 100; the silane coupling agent is vinyltriethoxysilane; the tackifier is C9 petroleum resin; the plasticizer is naphthenic oil; the viscosity of the naphthenic oil is 60-400CPS at 40°C; the antioxidant is antioxidant 264; the UV-resistant agent is composed of UV- 531 and UV-326 are compounded, and the mass ratio of the two is 1:1.

[0041] The present invention also provides a method for preparing the weather-resistant hot-melt pressure-sensitive adhesive, comprising the following steps:

[0042] (1) Put butyl rubber, plasticizer, tackifier, hydroxy acrylic resin, silane coupling agent into...

Embodiment 3

[0047] A weather-resistant hot-melt pressure-sensitive adhesive is composed of the following raw materials by mass percentage: 70% of butyl rubber, 2% of hydroxy acrylic resin, 15% of tackifier, 10% of plasticizer, 1% of silane coupling agent, Antioxidant 1% and UV Resistant 1%.

[0048] The unsaturation degree of the butyl rubber is 1.0%; the hydroxyl value of the hydroxy acrylic resin is 100; the silane coupling agent is vinyl tris(β-methoxyethoxy) silane; the The tackifier is terpene resin; the plasticizer is white oil; the white oil has a viscosity of 60-400CPS at 40°C; the antioxidant is antioxidant 1035; the UV-resistant The agent is composed of two kinds of UV-531 and UV-329, and the mass ratio of the two is 1:1.2.

[0049] The present invention also provides a method for preparing the weather-resistant hot-melt pressure-sensitive adhesive, comprising the following steps:

[0050] (1) Put butyl rubber, plasticizer, tackifier, hydroxy acrylic resin, silane coupling age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com