Ultrathin molybdenum disulfide nanosheet/polyimide self-lubricating composite material and preparation method thereof

A molybdenum disulfide and polyimide technology, which is applied in the field of ultra-thin molybdenum disulfide nanosheets/polyimide self-lubricating composite materials, can solve the problems of easy environmental pollution and difficult removal, and achieve a short running-in period. , low wear rate, the effect of enhancing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

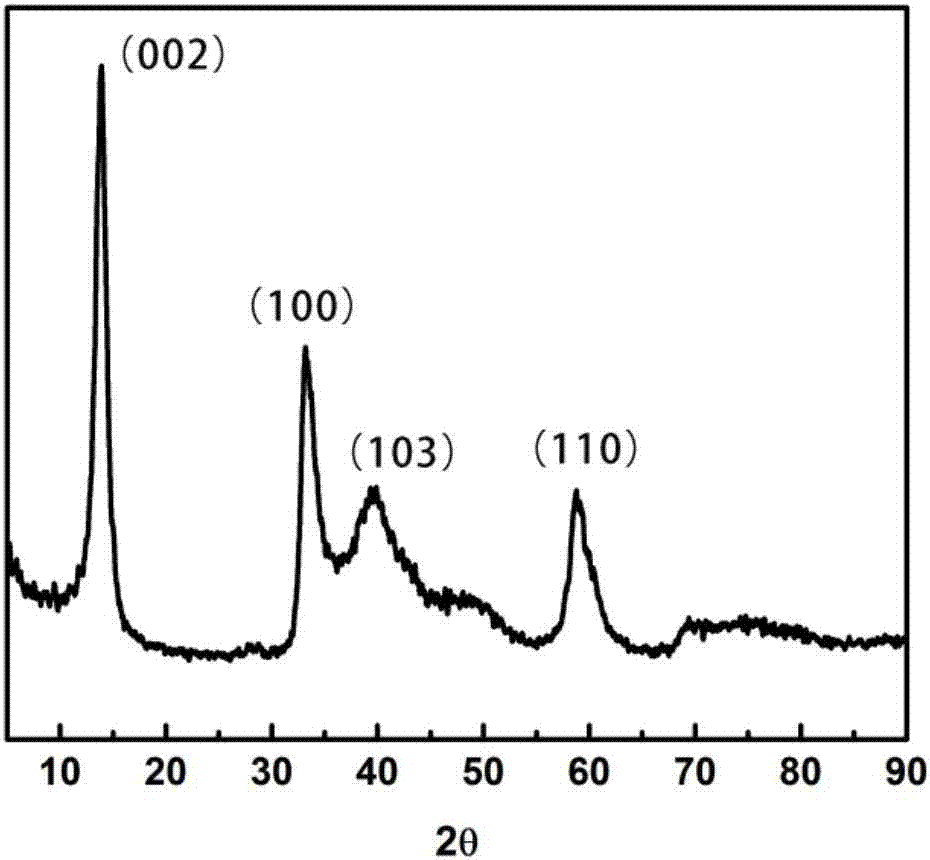

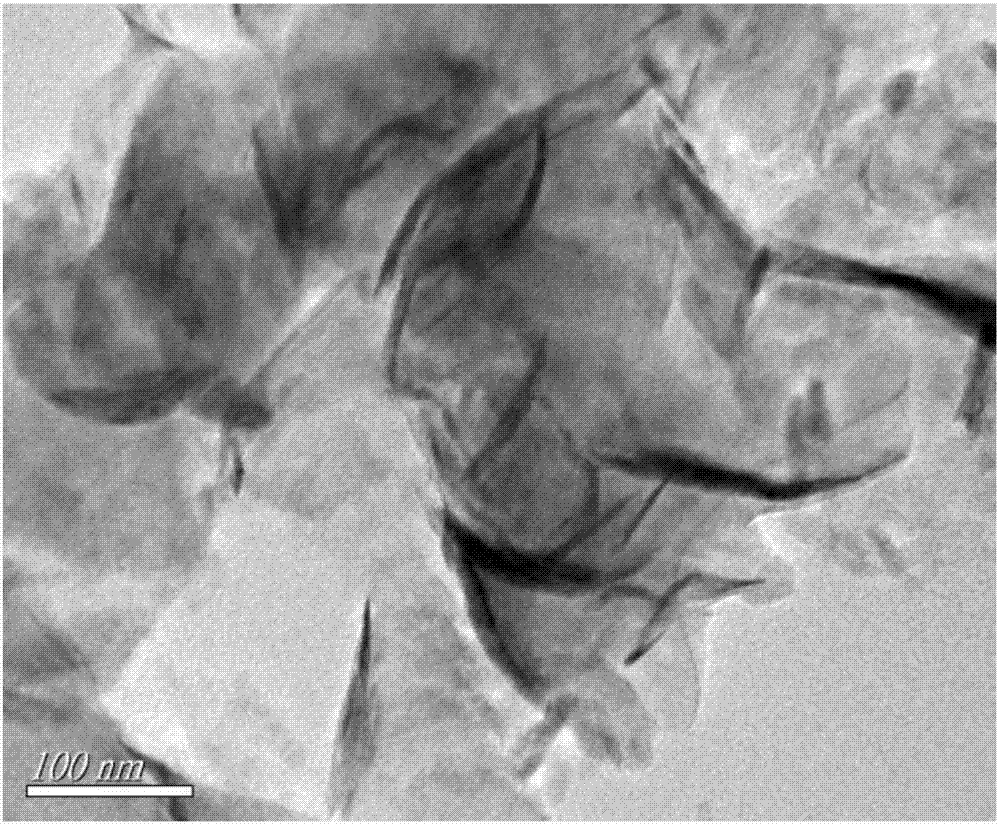

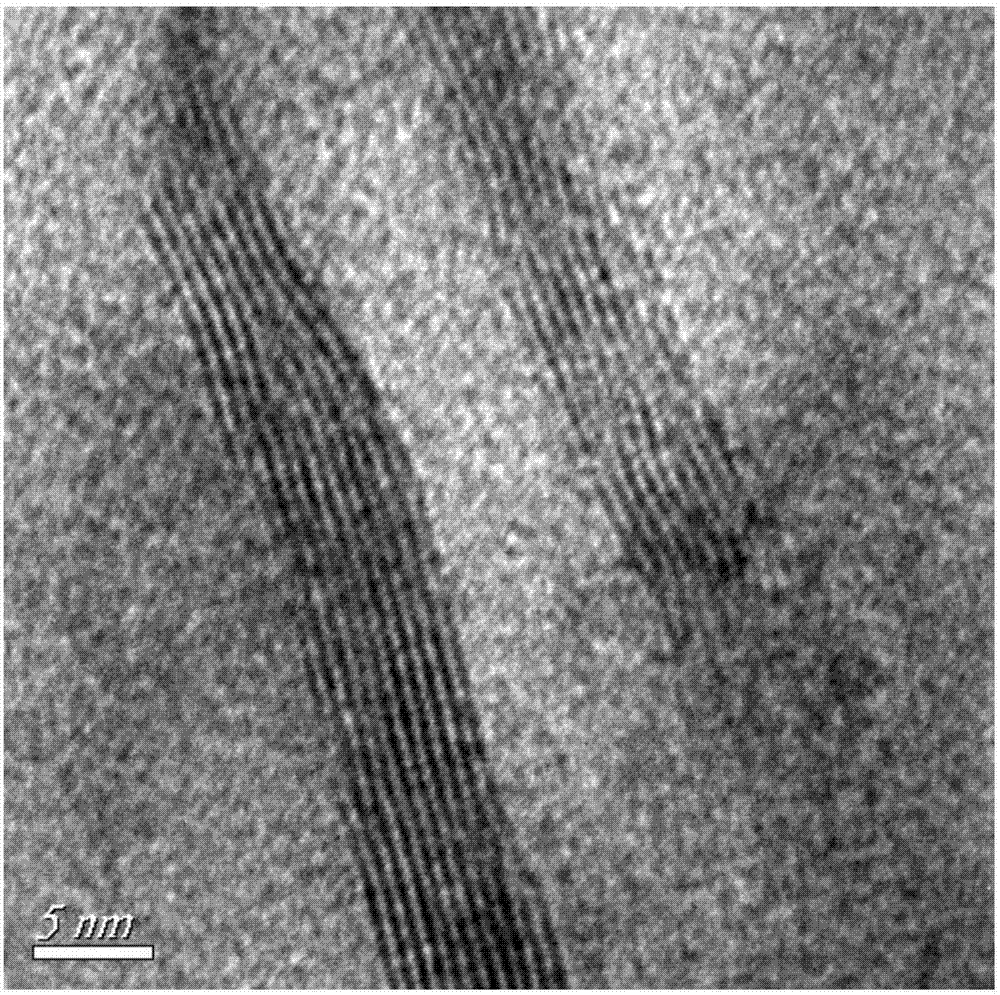

[0032] Dissolve ammonium molybdate tetrahydrate in deionized water to form a solution of 0.03mol / L, then add a certain proportion of thiourea (ammonium molybdate tetrahydrate: thiourea = 1:30 molar ratio), ultrasonically disperse and magnetically stir , after mixing, move it to a reactor for hydrothermal reaction, the reaction temperature is 220°C, and the reaction time is 22 hours. Then cool naturally, centrifuge, wash and dry to obtain ultra-thin molybdenum disulfide nanosheets. The X-ray diffraction pattern (XRD) of the obtained ultrathin molybdenum disulfide nanosheets is as follows: figure 1 , and its TEM appearance is as figure 2 and 3 . From figure 1 It can be seen that all the diffraction peaks are consistent with the standard card of pure hexagonal molybdenum disulfide (PDFNo.37-1492, and ) coincides, and no other impurity peaks appear, indicating that the prepared molybdenum disulfide purity is very high; from figure 2 It can be seen that molybdenum disulf...

Embodiment 2

[0034] Dissolve ammonium molybdate tetrahydrate in deionized water to form a solution of 0.03mol / L, then add a certain proportion of thiourea (ammonium molybdate tetrahydrate: thiourea = 1:30 molar ratio), ultrasonically disperse and magnetically stir , after mixing, move it to a reactor for hydrothermal reaction, the reaction temperature is 200°C, and the reaction time is 24 hours. Then cool naturally, centrifuge, wash, and dry to obtain ultra-thin molybdenum disulfide nanosheets with a thickness of about 4-6 nm, which is consistent with Example 1.

Embodiment 3

[0036] Dissolve ammonium molybdate tetrahydrate in deionized water to form a solution of 0.03mol / L, then add a certain proportion of thiourea (ammonium molybdate tetrahydrate: thiourea = 1:30 molar ratio), ultrasonically disperse for 20 minutes, Magnetic stirring was carried out for 30 minutes, and after mixing, the mixture was transferred to a reaction kettle for hydrothermal reaction. The reaction temperature was 220° C. and the reaction time was 20 hours. Then cool naturally, centrifuge, wash, and dry to obtain ultra-thin molybdenum disulfide nanosheets with a thickness of about 4-6 nm, which is consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com