Preparation method of amorphous or nanocrystalline soft magnetic powder core

A nanocrystalline soft magnetic and magnetic powder core technology, applied in the direction of magnetic materials, magnetic objects, metal processing equipment, etc., can solve the problems of low production efficiency, high mold and process requirements, complex temperature and pressure processes, etc., to eliminate internal stress, The effect of high soft magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

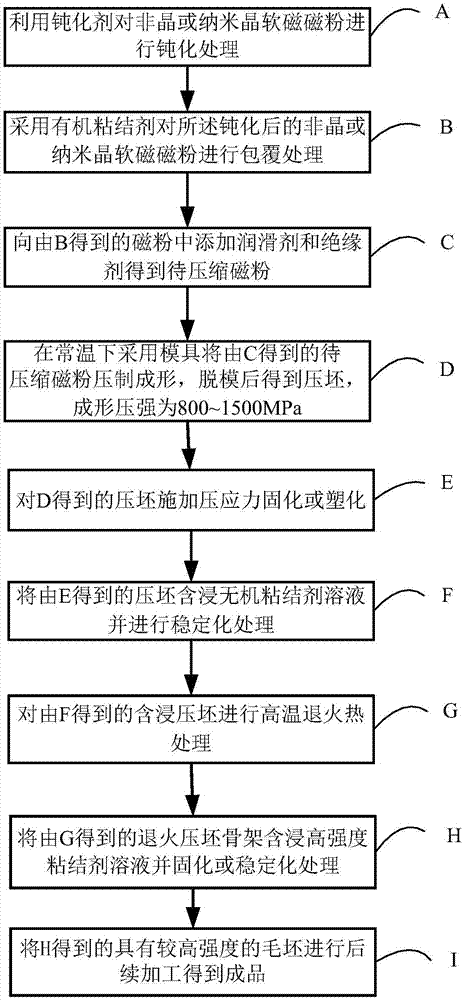

Method used

Image

Examples

Embodiment 1

[0049] Step 1: Nanocrystalline soft magnetic powder (molecular formula is Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 ) into a special passivation solution for passivation;

[0050] Step 2: dissolving the epoxy resin in acetone, the mass of the epoxy resin is 1% of the mass of the magnetic powder, and the amount of acetone is based on controlling the concentration of the acetone solution containing the epoxy resin at 7.0-7.5wt%;

[0051] Step 3: Put the nanocrystalline soft magnetic powder into the above epoxy resin solution to form a magnetic powder suspension. The suspension was stirred for 1 hour, put into an oven and baked at 80°C for 1 hour to completely volatilize the solvent, and obtain dry pre-compressed magnetic powder uniformly coated with epoxy resin;

[0052] Step 4: Add 0.2wt% zinc stearate and 1.0wt% mica powder to the above-mentioned pre-compressed magnetic powder, and mix well to obtain a pre-compressed mixed powder;

[0053] Step 5: Fill the mixed powder to be compres...

Embodiment 2

[0060] Step 1: Amorphous soft magnetic powder (molecular formula is Fe 78 Si 16 B 6 ) into a special passivation solution for passivation;

[0061] Step 2: uniformly mix 0.8wt% polyamide-6, 0.2wt% molybdenum disulfide, 0.6wt% mica powder, 0.4wt% kaolin powder and magnetic powder in a high-speed mixer to obtain pre-compressed mixed powder ;

[0062] Step 3: Fill the pre-compressed mixed powder into the mold, apply a pressure of 1200MPa, and obtain a compact after demoulding;

[0063] Step 4: Put the compact into the precision mold of the hot press machine, the radial dimension of the mold cavity is slightly larger than the compact by about 0.05mm, pressurize at 400MPa, temperature 230°C, hold time for 10min for plasticization, and demould after cooling;

[0064] Step 5: Vacuum impregnate the solidified compact with 20wt% sodium silicate solution, control the vacuum degree at about 50Pa, for 1-2min, and perform stabilization treatment in a vacuum oven at 170°C for 30min afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com