Glass-based chip and manufacturing method thereof

A technology of glass-based chips and manufacturing methods, which is applied to chemical instruments and methods, laboratory utensils, laboratory containers, etc., and can solve the problems of rising cost of processing glass-based microfluidic chips, difficulties in meeting usage requirements, and rough microchannels. It can solve the problems of high density, achieve good application prospects, save production time, and avoid environmental pollution by heavy metals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

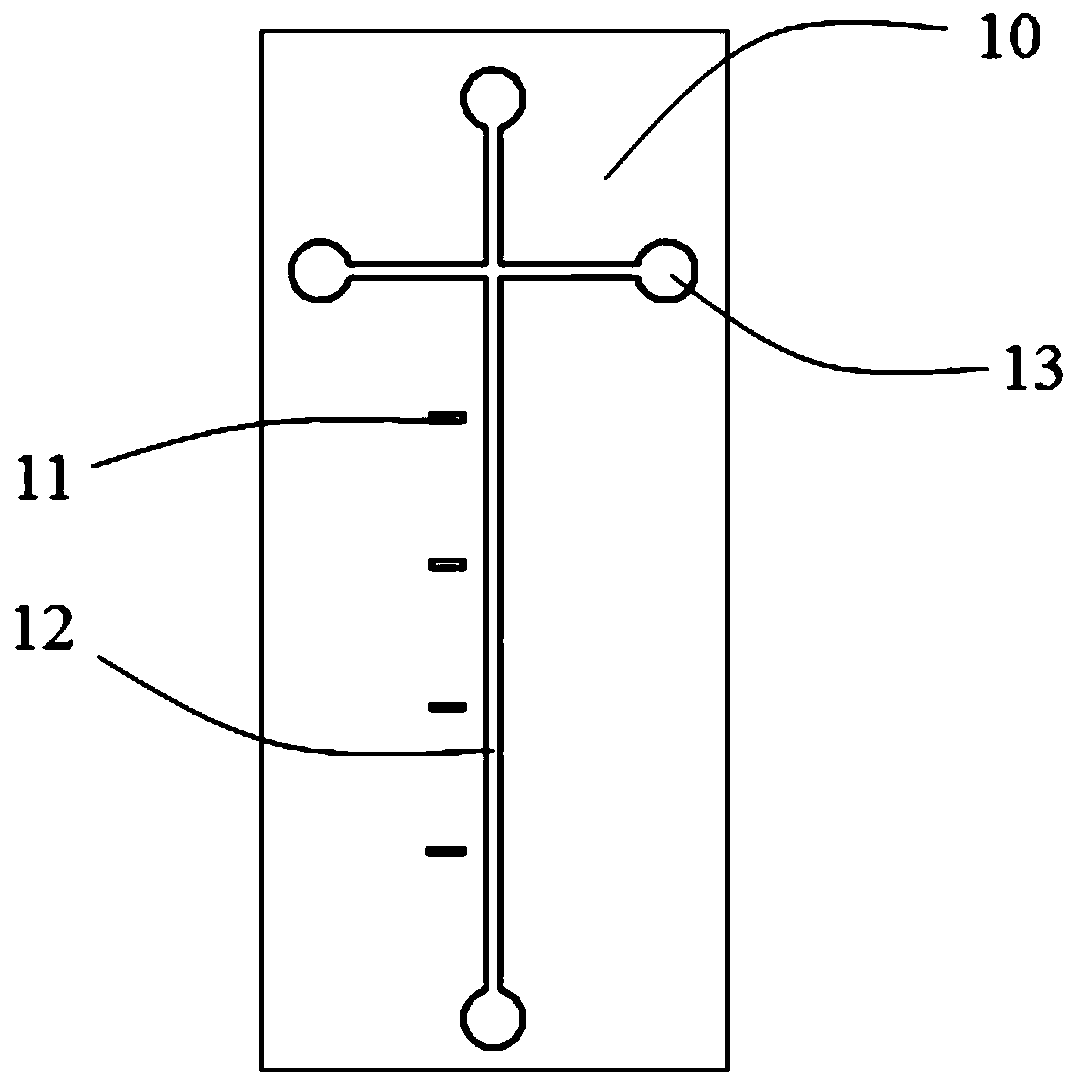

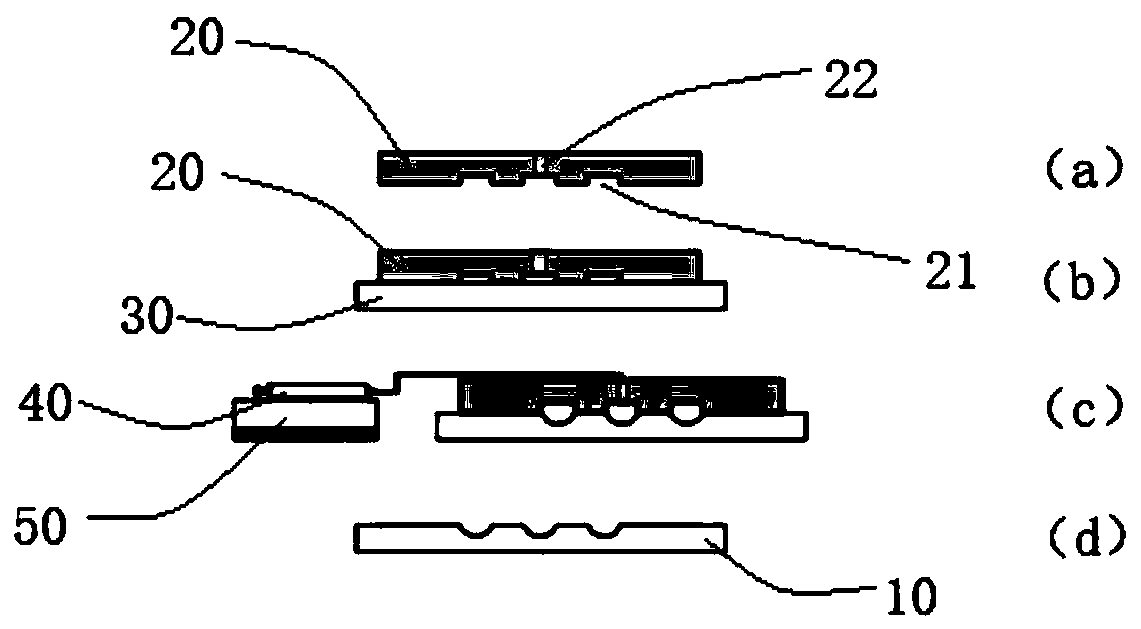

[0047] This embodiment provides a method for manufacturing a glass-based microfluidic chip. The glass-based microfluidic chip has a microchannel inside, the microchannel includes a first microchannel, and the first microchannel does not communicate with the atmosphere. The opening is a closed microstructure. In this embodiment, the glass-based microfluidic chip is further provided with an opening, the microchannel further includes a second microchannel, and both ends of the second microchannel are connected to the opening to form two An opening that communicates with the atmosphere. It can be understood that in other embodiments, both ends of the second microchannel can also be connected to the edge of the glass-based microfluidic chip to form an opening communicating with the atmosphere.

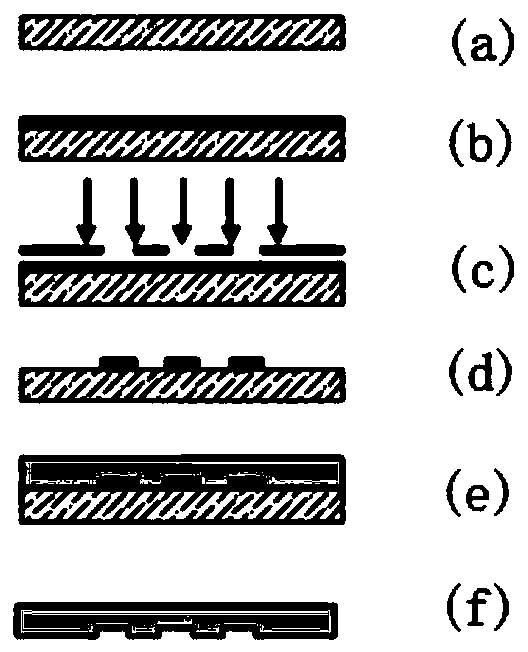

[0048] The above manufacturing method includes the following steps:

[0049] (1) Obtain bottom glass and cover glass;

[0050] (2) Clean the bottom glass sheet and the cover glass sheet, and bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com