Polymerization process of quantum dot doped PMMA (Polymethyl Methacrylate) body, light guide plate manufacturing process and light guide plate

A bulk polymerization and quantum dot technology, applied in the direction of light guide, optics and light guide doped with fluorescent agent, to achieve the effect of uniform distribution, improved light transmittance and good water and oxygen barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

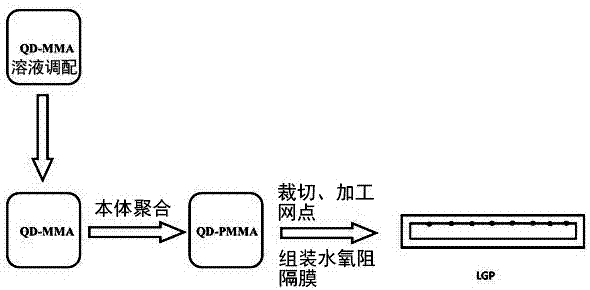

[0081] 1. Weigh a certain amount of methyl methacrylate (MMA), weigh 0.25% of the weight of MMA quantum dots, wherein the ratio of green quantum dots to red quantum dots is 50:1, and weigh 0.5% of the weight of MMA Cyclohexane solution, weighing 0.43% of the weight of MMA weight dibenzoyl peroxide (BPO).

[0082] 2. Dissolve quantum dots in cyclohexane solution, ultrasonically and oscillate to dissolve; add methyl methacrylate (MMA) dropwise to the above mixture, and shake well at the same time to fully disperse the quantum dot solution in MMA to form QD- MMA solution.

[0083] 3. Add dibenzoyl peroxide (BPO) into the QD-MMA solution prepared in step 2 and shake it to fully dissolve it. The water bath was refluxed and the temperature was controlled at 80°C to carry out the prepolymerization reaction. Observe the change of the solution every 10 minutes. When the viscosity of the solution gradually increases to form a viscous thin slurry, the solution is yellow and thick. Cool...

Embodiment 2

[0090] 1. Weigh a certain amount of methyl methacrylate (MMA), and weigh quantum dots whose weight is 1.25% of MMA weight, wherein the ratio of green quantum dots to red quantum dots is 50:1, and weigh 1.9% of MMA weight Cyclohexane solution, weighing 0.48% of the weight of MMA weight dibenzoyl peroxide (BPO).

[0091] 2. Dissolve quantum dots in cyclohexane solution, ultrasonically and oscillate to dissolve; add methyl methacrylate (MMA) dropwise to the above mixture, and shake well at the same time to fully disperse the quantum dot solution in MMA to form QD- MMA solution.

[0092] 3. Add dibenzoyl peroxide (BPO) into the QD-MMA solution prepared in step 2 and shake it to fully dissolve it. The water bath was refluxed and the temperature was controlled at 80°C to carry out the prepolymerization reaction. Observe the change of the solution every 10 minutes. When the viscosity of the solution gradually increases to form a viscous thin slurry, the solution is yellow and thick...

Embodiment 3

[0099] 1. Weigh a certain amount of methyl methacrylate (MMA), and weigh quantum dots whose weight is 1.00% of MMA weight, wherein the ratio of green quantum dots to red quantum dots is 50:1, and weigh 1.2% of MMA weight Cyclohexane solution, weighing 0.44% of the weight of MMA weight dibenzoyl peroxide (BPO).

[0100] 2. Dissolve quantum dots in cyclohexane solution, ultrasonically and oscillate to dissolve; add methyl methacrylate (MMA) dropwise to the above mixture, and shake well at the same time to fully disperse the quantum dot solution in MMA to form QD- MMA solution.

[0101] 3. Add dibenzoyl peroxide (BPO) into the QD-MMA solution prepared in step 2 and shake it to fully dissolve it. The water bath was refluxed and the temperature was controlled at 80°C to carry out the prepolymerization reaction. Observe the change of the solution every 10 minutes. When the viscosity of the solution gradually increases to form a viscous thin slurry, the solution is yellow and thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com