Nitrogen-doped ordered mesoporous carbon material and preparation method thereof

A mesoporous carbon and nitrogen doping technology, applied in the field of mesoporous materials, can solve the problems of high price, high nitrogen source corrosiveness, high catalyst cost, etc., and achieve the effects of low price and simple operation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of a nitrogen-doped ordered mesoporous carbon material N2-OMC in this embodiment (2 is the mass ratio of melamine and OMC):

[0027] Weigh 0.14g of concentrated sulfuric acid, 1.25g of sucrose and 5g of deionized water, mix well and add 1g of SBA-15 silicon-based solid to obtain a milky white suspension, then place the milky white suspension in a blast drying oven and dry at 90°C After 7 hours, the temperature was raised to 160°C for carbonization for 6 hours. The brown solid was taken out and ground into powder, and 0.09 g of concentrated sulfuric acid, 0.8 g of sucrose and 5 g of deionized water were added thereto, and the above drying and carbonization operations were repeated. The carbonized product was heated to 900° C. in a tube furnace under nitrogen atmosphere for 5 hours of high-temperature calcination. Then, the template agent SBA-15 was removed by heating under reflux with an ethanol aqueous solution containing 2mol / L NaOH (ethanol:water=1:1, vol...

Embodiment 2

[0031] Preparation of a nitrogen-doped ordered mesoporous carbon material N5-OMC in this embodiment (5 is the mass ratio of melamine and OMC):

[0032] Weigh 0.14g of concentrated sulfuric acid, 1.25g of sucrose and 5g of deionized water, mix well and add 1g of SBA-15 silicon-based solid to obtain a milky white suspension, then place the milky white suspension in a blast drying oven and dry at 100°C After 6 hours, the temperature was raised to 170°C for carbonization for 5 hours. The brown solid was taken out and ground into powder, and 0.09 g of concentrated sulfuric acid, 0.8 g of sucrose and 5 g of deionized water were added thereto, and the above drying and carbonization operations were repeated. The carbonized product was heated to 1000° C. in a tube furnace under nitrogen atmosphere for 3 hours of high-temperature calcination. Then, the template agent SBA-15 was removed by heating under reflux with an ethanol aqueous solution containing 2mol / L NaOH (ethanol:water=1:1, v...

Embodiment 3

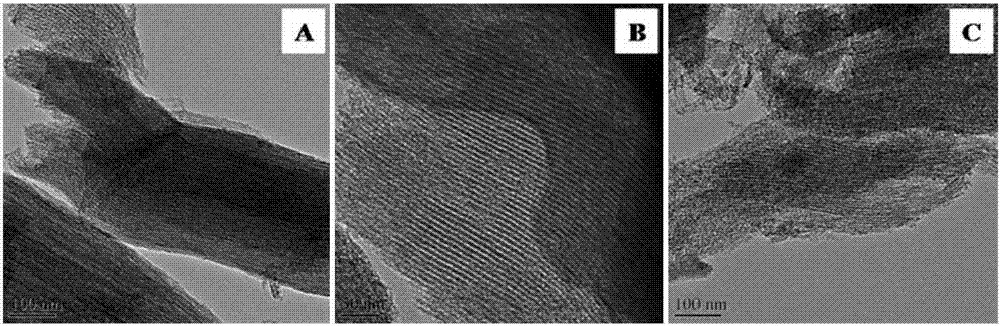

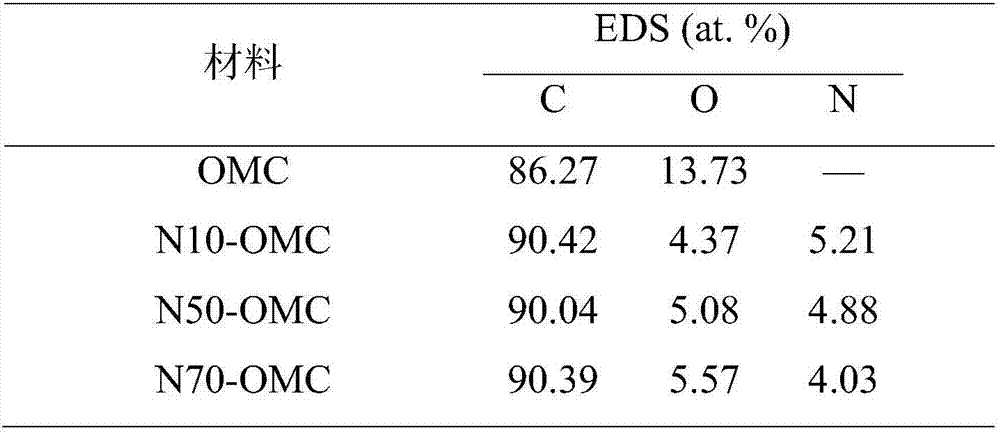

[0036] Preparation of a nitrogen-doped ordered mesoporous carbon material N10-OMC in this embodiment (10 is the mass ratio of melamine and OMC):

[0037] Weigh 0.14g of concentrated sulfuric acid, 1.25g of sucrose and 5g of deionized water, mix well and add 1g of SBA-15 silicon-based solid to obtain a milky white suspension, then place the milky white suspension in a blast drying oven and dry at 100°C After 7 hours, the temperature was raised to 150°C for carbonization for 8 hours. The brown solid was taken out and ground into powder, and 0.09 g of concentrated sulfuric acid, 0.8 g of sucrose and 5 g of deionized water were added thereto, and the above drying and carbonization operations were repeated. The carbonized product was heated to 900° C. in a tube furnace under nitrogen atmosphere for 4 hours of high-temperature calcination. Then, the template agent SBA-15 was removed by heating under reflux with 1 mol / L NaOH aqueous ethanol solution (ethanol:water=1:1, volume ratio)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com