Functionalized paper core wire for filtering rod and preparation method of functionalized paper core wire

A functionalized, core wire technology, applied in e-liquid filter, application, paper and other directions, can solve the problems of thermal collapse of paper impurity pressure drop, large fluctuation of cigarette suction resistance, affecting cigarette quality and other problems, and achieves good functional realization. , High production efficiency, good stability on the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

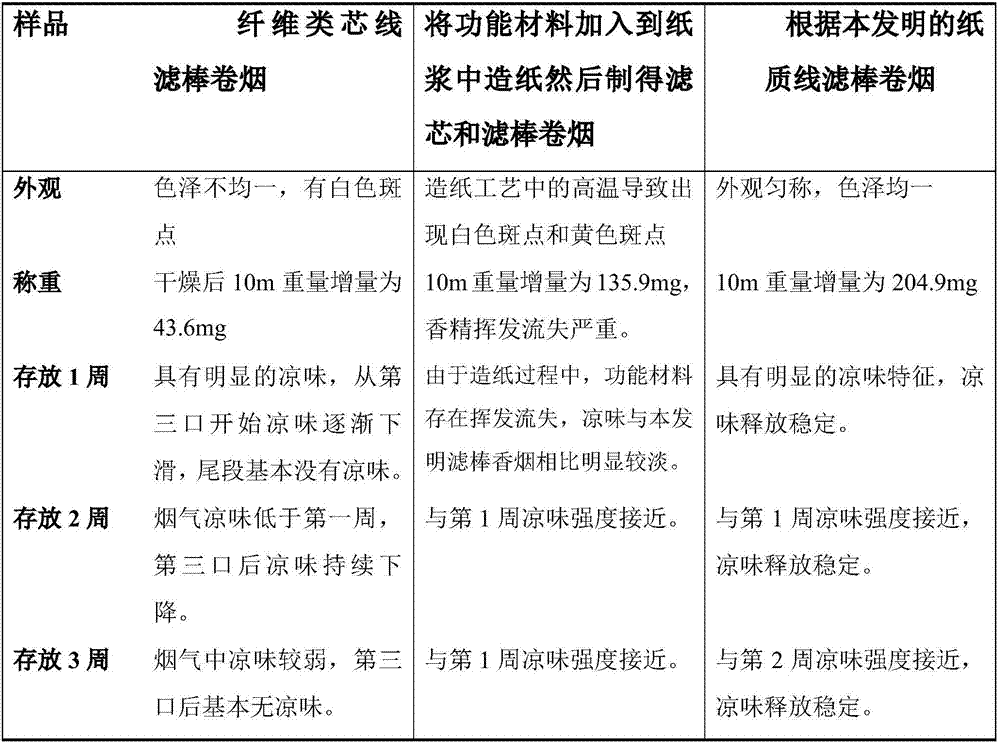

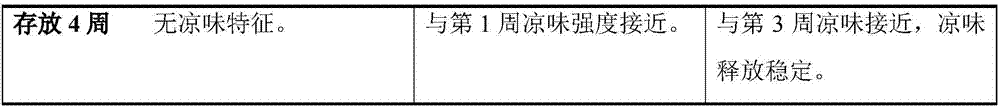

Examples

Embodiment 1

[0053] Adding 2.0% caramel pigment to the raw material for flavoring and flavoring tobacco to prepare flavoring and functional material liquid. And the functional material liquid at 20g / m 2 The added amount is printed on the untreated surface on one side by gravure printing, and the weight is 200g / m 2 On the natural plant fiber paper, after drying, the functionalized paper is cut into narrow roll paper with a width of 30mm. A strip of narrow paper is introduced into the forming equipment, and through the high-speed rotation of the machine shaft, the narrow paper is twisted into a strip-shaped core wire with a diameter of 3.0mm, and formed around a spindle to obtain a finished product.

Embodiment 2

[0055] Add 0.1% chlorophyll to the mint-flavored flavor-enhancing raw materials to prepare the flavor-enhancing functional material liquid. And functional material liquid at 0.1g / m 2 The added amount is double-sided printed on the surface by flexo printing and perforated, and the weight is 5g / m 2 On the natural plant fiber paper, the functionalized paper is cut into 1mm wide narrow roll paper after drying. 3 strips of narrow paper are introduced into the forming equipment, and through the high-speed rotation of the machine shaft, the narrow paper is twisted into a strip-shaped core wire with a diameter of 0.1mm, and formed by winding the spindle to obtain the finished product.

Embodiment 3

[0057] Polyethylene glycol, honey, sodium pyrrolidone carboxylate, maltooligosaccharide alcohol and sucrose ester are formulated into a 30% aqueous solution in a mass ratio of 6:4:6:3:3, and 0.5% carotene is added therein, Formulated as a moisturizing functional material liquid. And the functional material liquid at 0.5g / m 2 The added amount is printed on both sides by flexo printing on the surface after embossing treatment, and the weight is 20g / m 2 On the natural plant fiber paper, after drying, the functionalized paper is cut into narrow roll paper with a width of 10mm. Lead 2 strips of narrow paper into the forming equipment, through the high-speed rotation of the machine shaft, the narrow paper is twisted into a strip-shaped core wire with a diameter of 1.0mm, and formed by winding the spindle to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com