Method and device for quickly preparing graphene patterns through double beams

A graphene, double-beam technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of affecting the edge quality of graphene patterns, expensive continuous lasers, and high laser power density, etc. Achieve the effect of shortening preparation time, fast preparation speed and good edge quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

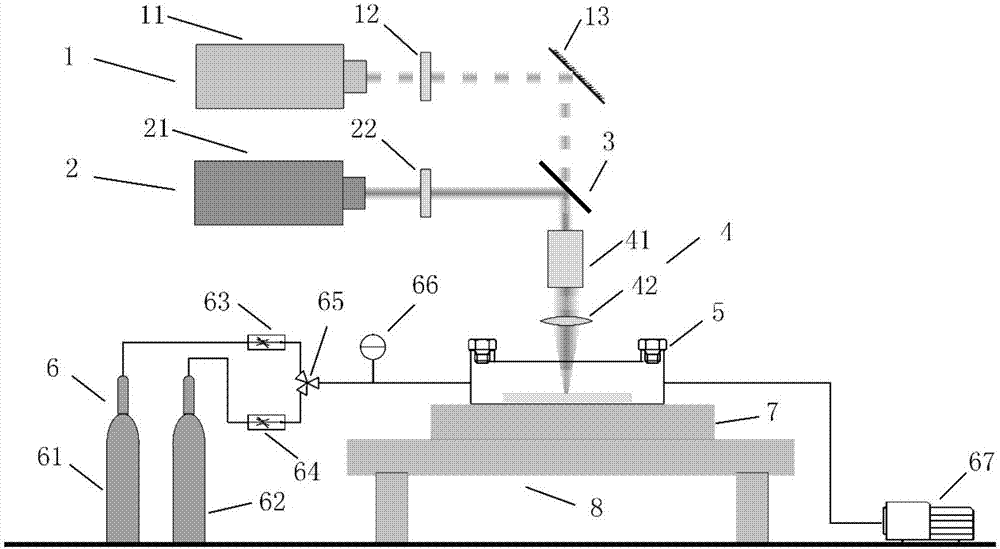

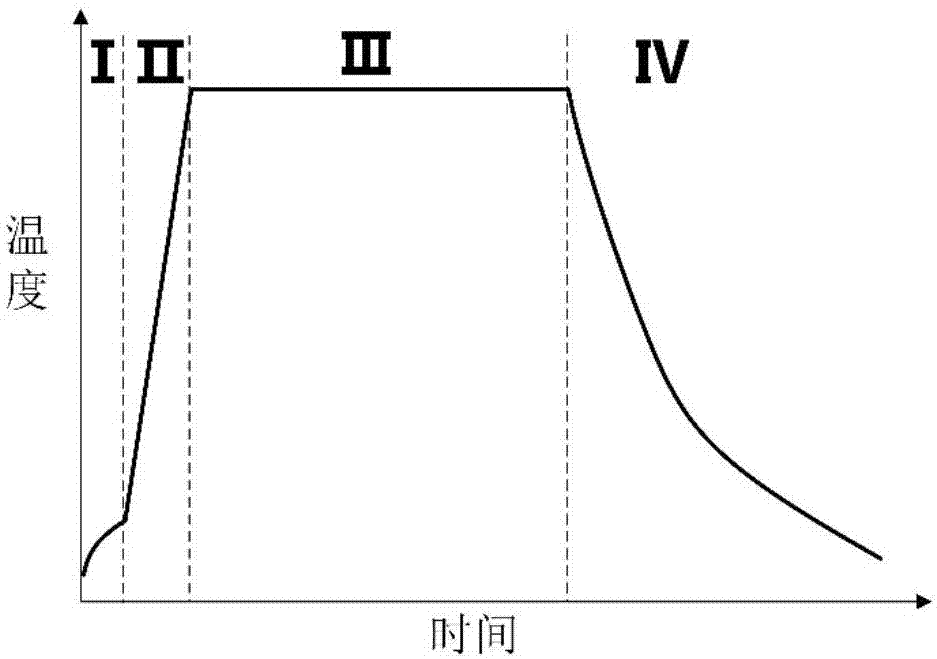

[0024] The following specific implementations will be combined with Figure 1~2 The present invention will be further explained.

[0025] Such as figure 1 Shown is a specific embodiment of the device in the present invention. The device includes a pulsed laser unit 1, a continuous laser unit 2, a dichroic mirror 3, a beam shaping and focusing unit 4, a vacuum cavity 5, a gas flow control unit 6, a three-axis precision translation stage 7 and an air-floating vibration isolation optical platform 8. .

[0026] The pulse laser unit 1 includes a pulse laser 11, a first laser shutter 12 and a mirror 13. The pulsed laser 11 is a nanosecond pulsed fiber laser with a power of 10W, a wavelength of 1064nm, and a pulse width of 1 nanosecond. The pulsed laser 11 is equipped with a controller to make the power and pulse repetition frequency adjustable. The adjustment range is 0.1Hz~1000Hz. Operation time of the laser shutter 12 <1 millisecond, when the first laser shutter 12 is closed, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com