Polymeric compound coating and preparation method and application thereof

A composite coating and polymer technology, applied in coatings, metal material coating technology, antifouling/underwater coatings, etc., can solve problems such as accumulation, harm to the marine ecological environment, and even human health, and achieve simple and excellent processes Anti-corrosion performance and anti-biofouling performance, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

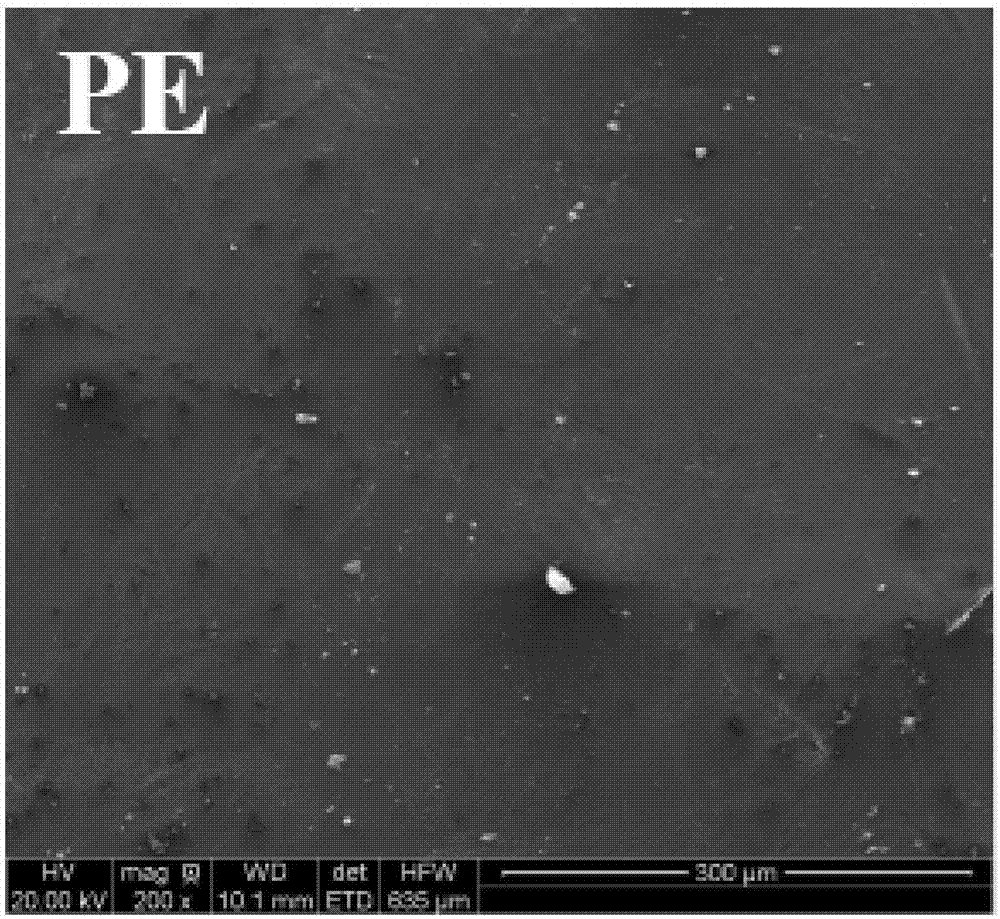

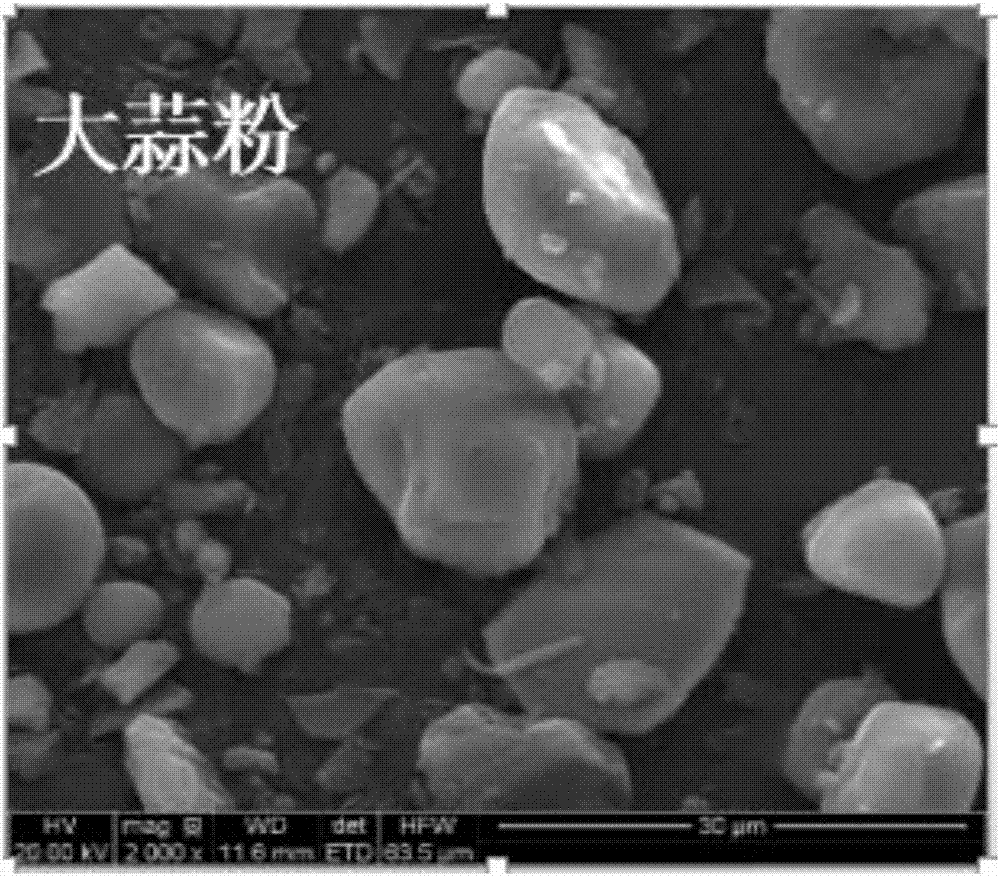

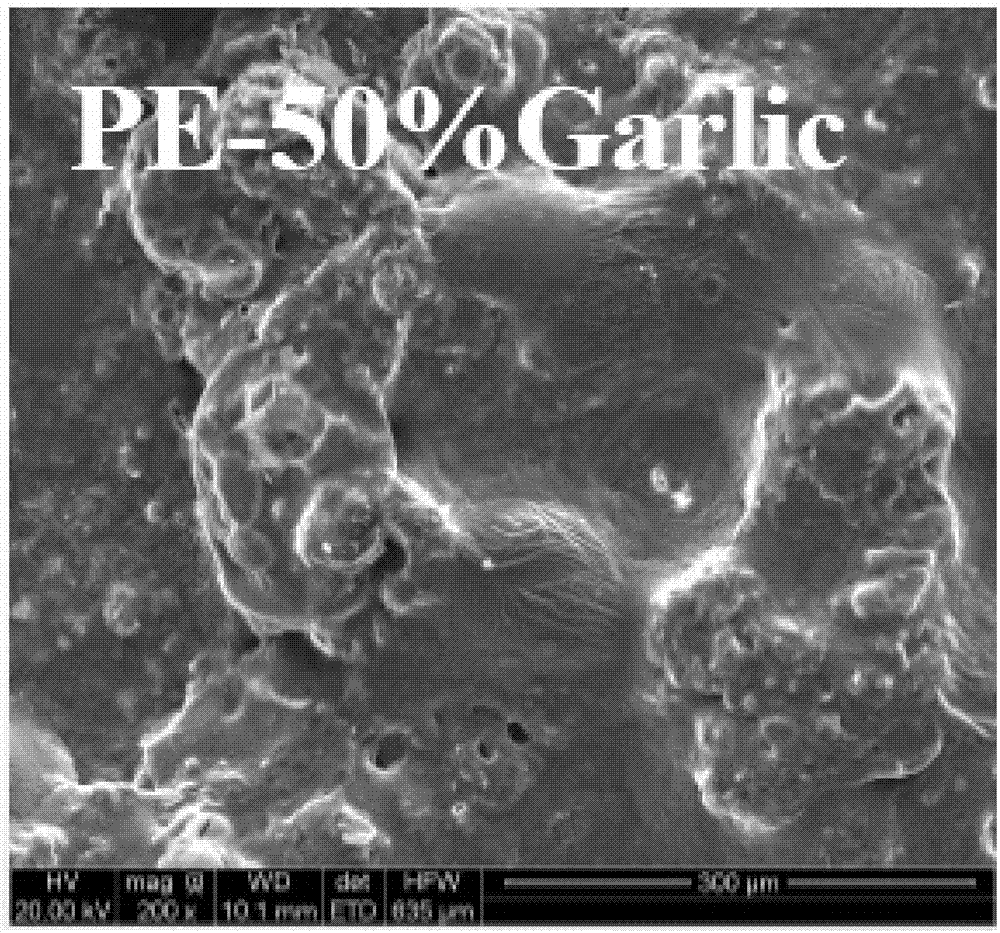

[0049] In the following three examples, the prepared polymer composite coating is a polyethylene / garlic powder composite coating, wherein the mass fraction of garlic powder is respectively 10%, 30%, and 50%, which are successively recorded as PE-10%Garlic, PE-30% Garlic and PE-50% Garlic. The thickness of the coating is 80 μm, the substrate is a Q235 steel sheet with a thickness of about 2 mm, and the coating is well combined with the substrate material.

[0050] The concrete preparation method of this polyethylene / garlic powder composite coating is as follows:

[0051] 1. Weigh 100g of polyethylene (PE) powder, ultrasonically, and dry; add garlic powder (about 20 μm in size) to the polyethylene powder in proportion, and mechanically stir until uniform, and finally obtain a mixed powder of polyethylene / garlic powder;

[0052] 2. Clean the substrate with acetone, ethanol, and deionized water in sequence, and use 60 mesh brown corundum sand to roughen the surface of the Q235 st...

Embodiment 4~6

[0060] In the following three examples, the prepared polymer composite coating is polyethylene / paprika composite coating, wherein the mass fraction of paprika is respectively 10%, 30%, 50%, and the coating thickness is 80 μm, and the substrate is For Q235 steel sheets with a thickness of about 2mm, the coating is well combined with the base material.

[0061] The concrete preparation method of this polyethylene / paprika composite coating is as follows:

[0062] 1. Weigh 100g of polyethylene (PE) powder, ultrasonically, and dry; add chili powder (about 20 μm in size) to the polyethylene powder in proportion, and mechanically stir until uniform, and finally obtain a mixed powder of polyethylene / paprika;

[0063] 2. Clean the substrate with acetone, ethanol, and deionized water in sequence, and use 60 mesh brown corundum sand to roughen the surface of the Q235 steel sheet. The air pressure used for sandblasting is 0.5MPa to make its roughness reach the Requirements, it is benefic...

Embodiment 7~9

[0070] In the following three examples, the prepared polymer composite coating is a polyethylene / ginger powder composite coating, wherein the mass fraction of ginger powder is respectively 10%, 30%, 50%, and the coating thickness is 80 μm, and the matrix is For Q235 steel sheets with a thickness of about 2mm, the coating is well combined with the base material.

[0071] The concrete preparation method of this polyethylene / ginger powder composite coating is as follows:

[0072] 1. Weigh 100g of polyethylene (PE) powder, ultrasonically, and dry; add ginger powder (about 20 μm in size) to the polyethylene powder in proportion, and mechanically stir until uniform, and finally obtain a mixed powder of polyethylene / ginger powder;

[0073] 2. Clean the substrate with acetone, ethanol, and deionized water in sequence, and use 60 mesh brown corundum sand to roughen the surface of the Q235 steel sheet. The air pressure used for sandblasting is 0.5MPa to make its roughness reach the Req...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com