Culture solution for bacillus, preparation method and application thereof

A Bacillus and Bacillus subtilis technology, applied in the field of microbial fertilizers and microbial pesticides, can solve the problems of reduced use effect, increased production cost, reduced number of effective viable bacteria, etc., and achieves improved use effect, improved use effect, and reduced production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation method and application of bacillus amyloliquefaciens microbial agent

[0032] 1. The preparation method is as follows:

[0033] Clean the equipment before culturing, and clean the fermenter and its accessories with tap water until there is no culture residue. Take 2.00% soluble starch, 1.00% soybean protein powder, 0.50% yeast powder, 0.30% KH 2 PO 4 , 0.05% MgSO 4 ·7H 2 O, 0.02% MnSO 4 ·H 2 O, 0.08% NaOH was added to the expansion tank to prepare the basic culture solution, and then 1.00‰ defoamer was added to replenish the water to 140L. Heat the culture solution to 100°C and heat-treat for 30-60 minutes, then cool down to 80°C, add 1.00% Bacillus amyloliquefaciens seeds to the culture solution and heat-treat for 30 minutes, then ventilate and cool down to 35°C.

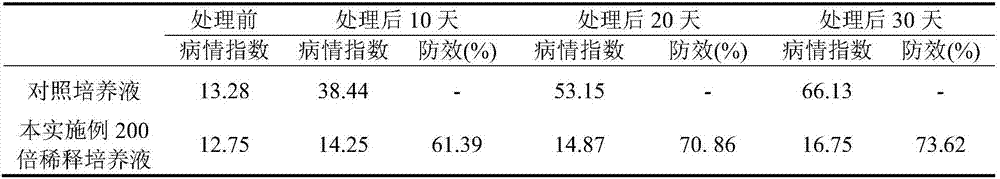

[0034] The above-mentioned obtained liquid is cultivated with air, and the culture conditions are about 0.8-1.0vvm ventilation, 32°C temperature, and 36-48h culture time, and the culture l...

Embodiment 2

[0041] Preparation method and application of Bacillus subtilis microbial agent

[0042] 1. The preparation method is as follows:

[0043] Clean the equipment before expanding the cultivation, and clean the hot water tank and its accessories with tap water until there is no culture residue. Pass corn starch and soybean powder through a 60-mesh sieve, take 1.50% corn starch, 0.50% soybean powder, 0.50% corn syrup powder, and 0.20% KH 2 PO 4 , 0.03% MgSO 4 ·7H 2 O, 0.01% MnSO 4 ·H 2O, 0.10% NaOH was added to the expansion tank to prepare the basic culture solution, and then 1.00‰ defoamer was added to replenish the water to 140L. Heat the culture solution to boiling, add 1.00wt‰ Bacillus subtilis seeds into the culture solution for heat treatment for 30 minutes, then ventilate and cool down to 42°C.

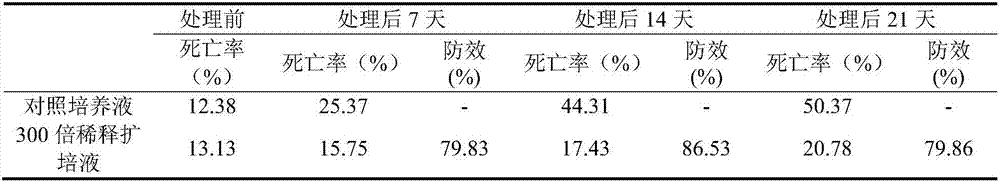

[0044] The above-mentioned obtained liquid is cultivated with air, and the culture conditions are about 1.0vvm ventilation, 30-37°C temperature, and 36h culture time. The cul...

Embodiment 3

[0051] Preparation method and application of bacillus licheniformis microbial agent

[0052] 1. The preparation method is as follows:

[0053] Clean the equipment before the expansion, and clean the expansion tank and its accessories with tap water until there is no culture residue. Pass the peanut powder through a 60-mesh sieve, weigh 2.00% sucrose, 1.00% peanut powder, 0.30% yeast extract, 0.30% KH 2 PO 4 , 0.04% MgSO 4 ·7H 2 O, 0.02% MnSO 4 ·H 2 O, 0.07% NaOH was added to the expansion tank to prepare the basic culture solution, then 1.00‰ defoamer was added to the expansion tank, and the water was replenished to 400L. After heating the culture solution to 80°C, take 0.50% Bacillus licheniformis inoculum and add it to the culture solution for 20 minutes, then ventilate and cool down to 42°C.

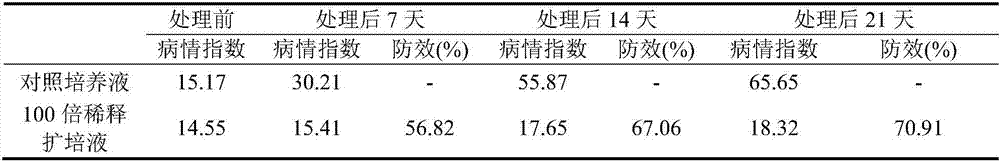

[0054] The liquid obtained above was cultivated with air under the conditions of ventilation of about 0.5-1.0vvm, temperature of 32°C, and incubation time of 24 hours, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com