Recombinant Escherichia coli construction and (S)-2-hydroxy-3-phenylpropionic acid synthesis method

A technology for recombining Escherichia coli and Bacillus megaterium, applied in the biological field, can solve the problems of inability to produce L-PLA and low production efficiency of synthetic PLA, and achieve the effects of increasing yield and yield, wide application, and simple culture conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

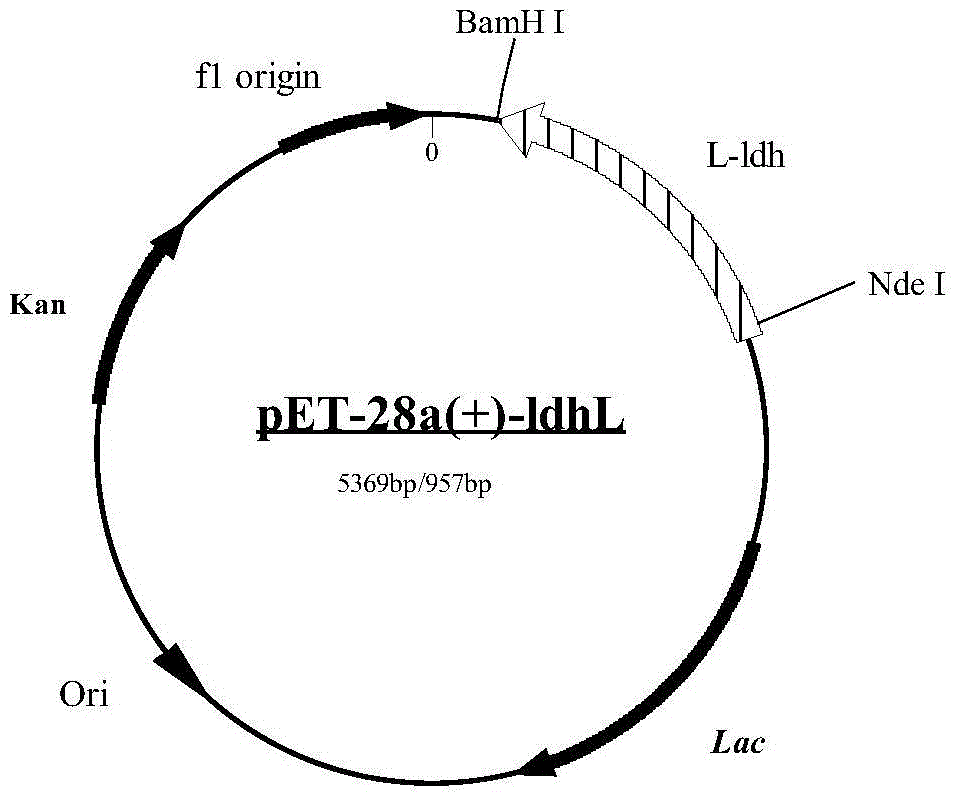

[0035] This example illustrates recombinant E. coli E. coli Construction of BL21(DE3) / pET-28a-ldhL.

[0036] 1. L-lactate dehydrogenase derived from Bacillus megaterium Bacillus megaterium Z2013513 (CCTCC NO: M2013244), optimizes the codons of the L-LDH gene according to the codon preference of Escherichia coli, and its nucleotide sequence is shown in SEQ ID NO:1.

[0037] 2. The codon-optimized L-lactate dehydrogenase gene was obtained by artificial synthesis, and the upstream and downstream primers were designed. The primer sequences are shown in SEQ ID NO: 2 and SEQ ID NO: 3. After PCR amplification, the nucleic acid agarose gel electrophoresis gel was recovered, connected to the pMD19-T vector, and the cloning vector was transformed into E. coli JM109 gets E. coli JM109-pMD-ldhL, the recombinant plasmid was extracted for double enzyme digestion verification, and the verified positive clones were E. coli The nucleotide sequence of JM109-pMD-ldhL was sequenced. ...

Embodiment 2

[0039] This example illustrates the preparation of recombinant E. coli whole cells.

[0040] (1) Strain activation: pick E. coli A single colony of BL21(DE3) / pET-28a-ldhL was inoculated into 10 mL LB liquid medium (containing 50 mg / L kanamycin), and cultured overnight at 37 °C and 200 r / min.

[0041] (2) Seed culture: Add the culture solution obtained in the above step 1) into 100 mL LB medium (containing 50 mg / L kanamycin) according to the inoculum amount (volume fraction) of 1%, at 37 °C, 200 r / min cultured cell OD 600 It is 0.4~1.0.

[0042](3) Induced expression: IPTG was added to the bacterial liquid obtained in the above 4), and cultured at 25 °C, 200 r / min for 4-6 h to the mid-log phase of cell growth, and the obtained culture liquid was incubated at 4 °C, 6000 r / min Centrifuge for 5 min, wash twice with sterilized sodium phosphate buffer (0.1 mol / L, pH=7.0) to obtain resting cells.

Embodiment 3

[0044] This example illustrates whole cell batch catalytic synthesis of L-PLA.

[0045] (1) Transformation of whole cells: suspend the cells obtained in Example 2 above with 5 ml of transformation solution, and pour into a 100 ml Erlenmeyer flask. The transformation solution contained 0.1 mol / L sodium phosphate buffer and 100 mmol / L glucose. After the bacteria slime is fully and evenly suspended in the transformation solution, add 5 ml of 70 mmol / L PPA solution to obtain a final concentration of 35 mmol / L, mix well and carry out the transformation reaction on a shaker at a reaction temperature of 37 °C and 200 r / min Shake the reaction for 60 min.

[0046] (2) Centrifuge the reaction conversion liquid obtained in the above step 1) at 4 °C and 10000 r / min for 2 min, then take the supernatant, and use high performance liquid chromatography to measure the content of L-PLA. The detection conditions are: chiral column OJ -RH, mobile phase (volume ratio): acetonitrile: methanol: tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com