Tetravalent platinum complex oxidant and preparation method and application thereof

A complex, tetravalent platinum technology, applied in the field of tetravalent platinum complex oxidant and its preparation, can solve the problems of high reaction system requirements, slow reaction rate, low reaction yield and the like, and achieves fast reaction rate, simple preparation, The effect of simple reaction solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

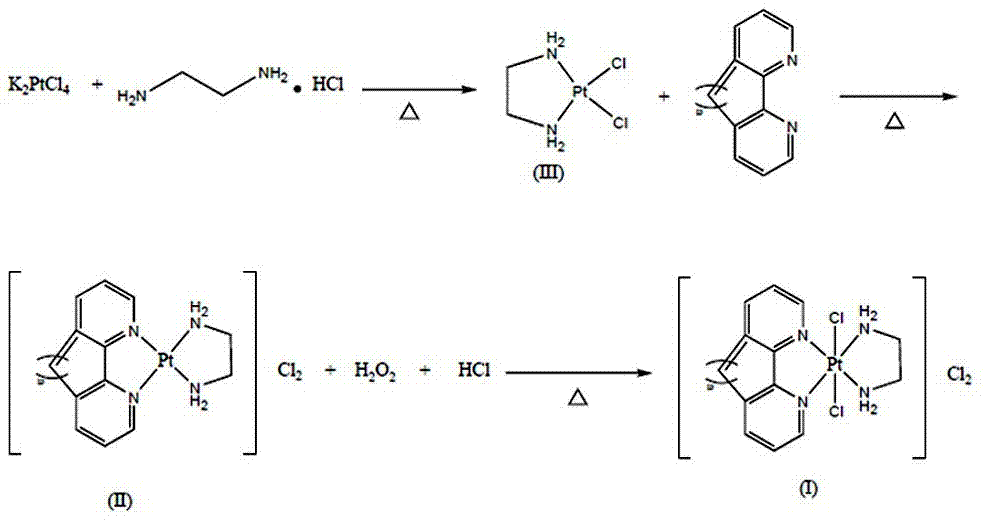

[0058] ①In a 50 mL three-necked flask, add 0.2 g of potassium tetrachloroplatinate and 20 mL of 50 mM hydrochloric acid solution, then add 200 μL of ethylenediamine, magnetically stir, and reflux at 100°C for 15 h; after the reaction is completed, cool to After filtering at room temperature, the resulting solid was washed three times with ethanol, and then dried in vacuum at 50°C for 12 hours to obtain a yellow dichloro(ethylenediamine) platinum complex;

[0059] ② Add 0.1 g dichloro(ethylenediamine) platinum into a 50 mL single-necked bottle, then add 50 mL water, add 0.3 g o-phenanthroline after ultrasonic dispersion, stir, and react at 100 ° C for 50 h; cool down after the reaction to room temperature, filtered, the light yellow filtrate was concentrated to 3-6 mL, and then 100 mL of acetonitrile was added, a light yellow solid precipitated, filtered, the solid was washed with acetonitrile for 3 times, and then vacuum-dried to obtain a light yellow ionic divalent platinum co...

Embodiment 2

[0063] ①In a 50 mL three-necked flask, add 0.2 g of potassium tetrachloroplatinate and 20 mL of 50 mM hydrochloric acid solution, then add 200 μL of ethylenediamine, magnetically stir, and reflux at 100°C for 12 h; after the reaction is completed, cool to After filtering at room temperature, the obtained solid was washed with ethanol three times, and then dried in vacuum at 50°C for 12 hours to obtain a yellow dichloro(ethylenediamine) platinum complex;

[0064] ② Add 0.2 g of dichloro(ethylenediamine) platinum into a 50 mL single-necked bottle, then add 100 mL of water, add 0.5 g of 2,2′-bipyridine after ultrasonic dispersion, stir, and react at 100°C for 72 h After the reaction is completed, cool to room temperature, filter, and concentrate the light yellow filtrate to 3-5 mL, then add 80 mL of acetonitrile, a light yellow solid precipitates, filter, wash the solid 3 times with acetonitrile, and then dry in vacuo to obtain light yellow ionic di Valence platinum complexes;

...

Embodiment 3

[0068] The oxidizing agent prepared in the present invention (that is, the tetravalent platinum complex) can react with various reduced polypeptides containing sulfhydryl groups to synthesize disulfide bonds in polypeptide molecules.

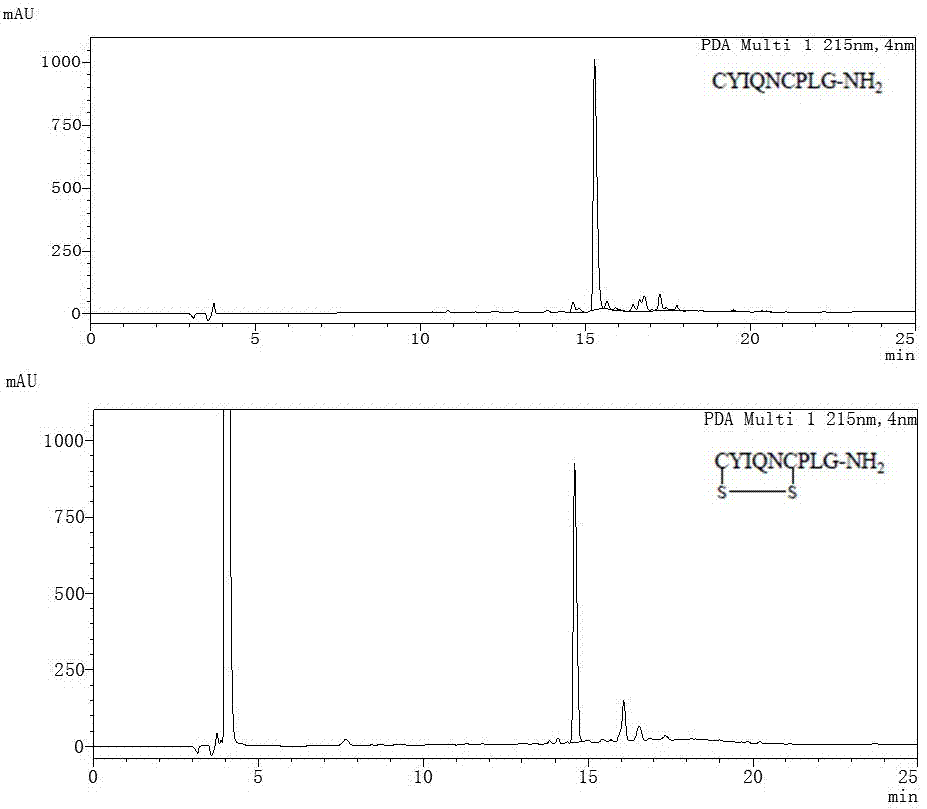

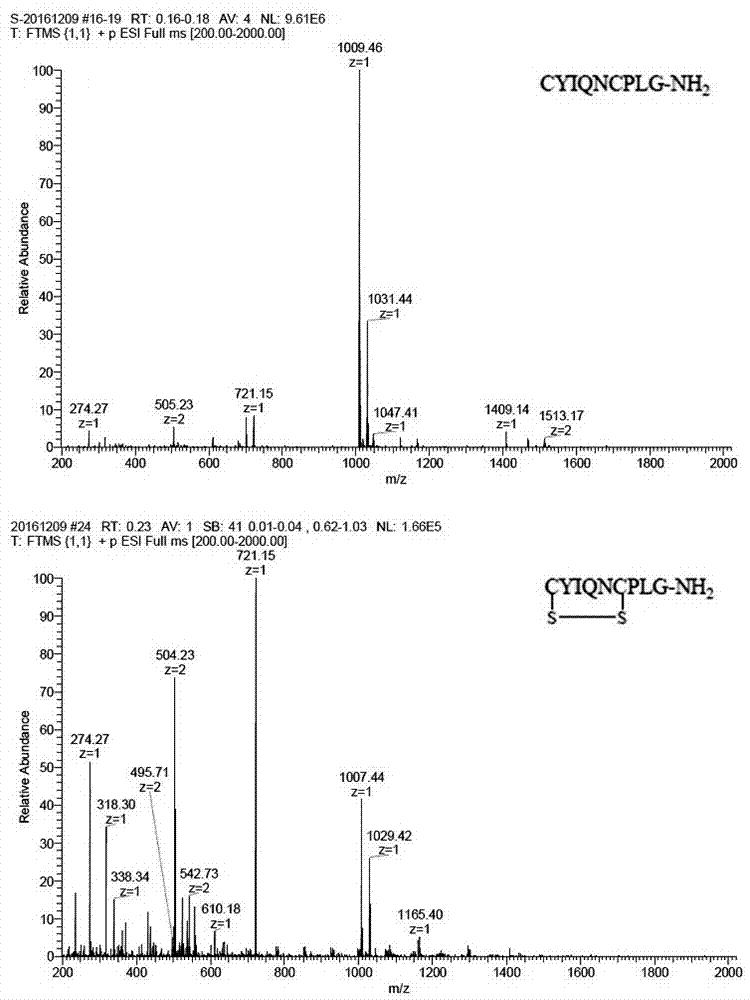

[0069] Using the tetravalent platinum complex prepared in Example 1 and Example 2 and the reduced polypeptide containing sulfhydryl group to synthesize intramolecular disulfide bonds of the polypeptide through the following scheme: react the tetravalent platinum complex with the reduced polypeptide solution at room temperature for 1 ~5min; after the reaction, the reaction product was separated by high performance liquid chromatography, and the reaction product was identified by mass spectrometry.

[0070] The oxidizing agent of the present invention can oxidize a variety of reduced polypeptides containing two sulfhydryl groups. These polypeptides are synthesized by the traditional solid-phase polypeptide synthesis method. The polypeptide, the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com