Synthetic method of 3-aminomethyl tetrahydrofuran

A technology of aminomethyltetrahydrofuran and a synthesis method, applied in the field of nicotinic insecticide dinotefuran, can solve the problems of unsuitability for industrial large-scale production, cumbersome reaction, long route and the like, and achieves strong safety and operability , The effect of simple process and high overall yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

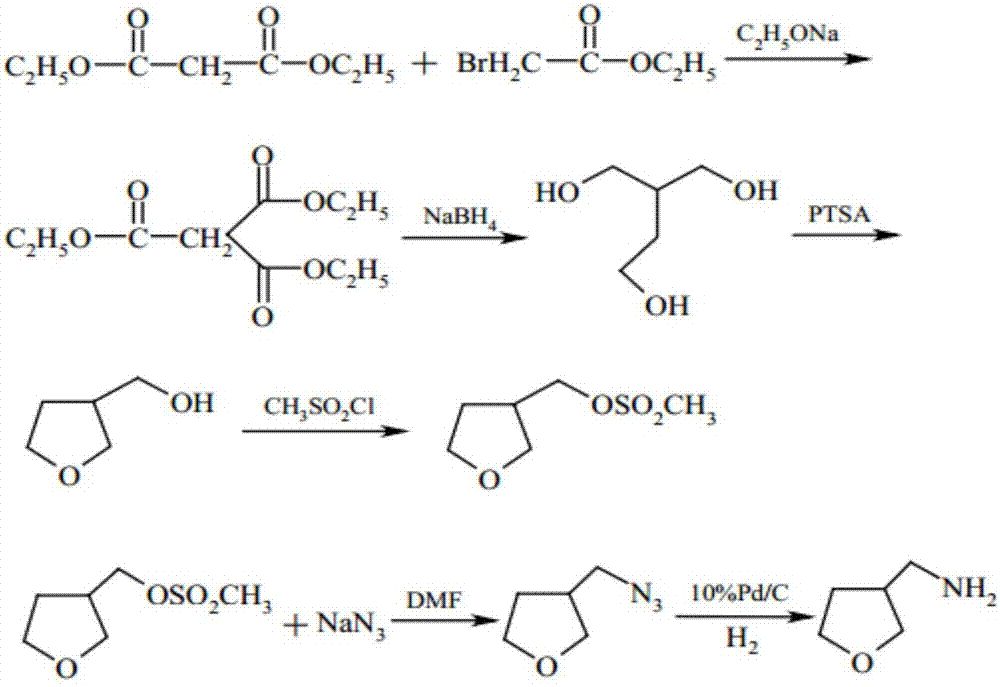

Problems solved by technology

Method used

Image

Examples

Embodiment 1

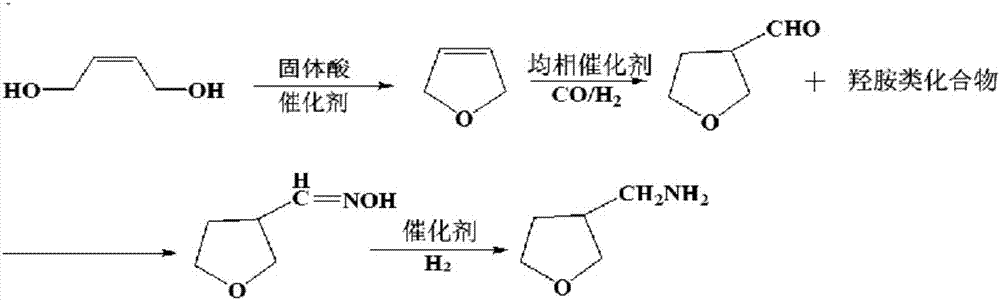

[0032] like figure 2 As shown, this embodiment includes the following steps:

[0033] Step 1. In a three-neck flask with a volume of 2L, add 1320g (15mol) of 1,4-butenediol, then add 1.32g of phosphotungstic heteropoly acid solid, and react at 250°C for 8h to obtain 2,5-dihydrofuran 1000g (14.3mol), the yield of the 2,5-dihydrofuran is 95.2%;

[0034] Step 2. Mix 1000g (14.3mol) of 2,5-dihydrofuran prepared in step 1 with 2L of methanol in an autoclave with a volume of 5L, and then add 20g of homogeneous catalyst HRhCO[P(Ph) 3 ] 3 , feed reaction gas into the autoclave to raise the pressure in the autoclave to 2 MPa, stir for 10 h at a temperature of 90° C., then lower the temperature, exhaust the gas, release the reaction product liquid, and distill off the methanol. Distillation obtains 3-formaldehyde tetrahydrofuran 1315g, and the yield of described 3-formaldehyde tetrahydrofuran is 92%; Described reaction gas is made of CO and H 2 Mixed according to the volume ratio o...

Embodiment 2

[0044] like figure 2 As shown, this embodiment includes the following steps:

[0045] Step 1. In a three-neck flask with a volume of 2L, add 1320g (15mol) of 1,4-butenediol, add 2g of ZSM-5 molecular sieve, and react at 230°C for 7h to obtain 1018g (14.5mol) of 2,5-dihydrofuran ), the yield of the 2,5-dihydrofuran is 97%;

[0046] Step 2. Mix 1018g (14.5mol) of 2,5-dihydrofuran prepared in Step 1 with 2L of ethanol in an autoclave with a volume of 5L, and then add 0.509g of homogeneous catalyst HRhCO[P(PhF) 3 ] 3 , feed reaction gas into the autoclave to raise the pressure in the autoclave to 4MPa, stir at 90°C for 18 hours, then lower the temperature, exhaust, release the reaction product liquid, and distill off ethanol, Distillation obtains 3-formaldehyde tetrahydrofuran 1396g, and the yield of described 3-formaldehyde tetrahydrofuran is 96%; Described reaction gas is made of CO and H 2 Mixed according to the volume ratio of 1:1;

[0047] Step three, mix 1396g (13.9mol...

Embodiment 3

[0051] like figure 2 As shown, this embodiment includes the following steps:

[0052] Step 1. In a three-neck flask with a volume of 2L, add 1320g (15mol) of 1,4-butenediol, add 4.4g of phosphomolybdoheteropolyacid solid, and react at 230°C for 5h to obtain 966g of 2,5-dihydrofuran (13.8mol), the yield of the 2,5-dihydrofuran is 92%;

[0053] Step 2. Mix 966g (13.8mol) of 2,5-dihydrofuran prepared in step 1 with 2.5L methanol in an autoclave with a volume of 5L, and then add 19.3g of homogeneous catalyst HRhCO[P(PhSO 3 Na) 3 ] 3 , feed reaction gas into the autoclave to raise the pressure inside the autoclave to 7MPa, stir for 15 hours at a temperature of 60°C, then lower the temperature, exhaust the gas, release the reaction product liquid, and distill off the methanol. Distillation obtains 3-formaldehyde tetrahydrofuran 1311g, and the yield of described 3-formaldehyde tetrahydrofuran is 95%; Described reaction gas is made of CO and H 2 Mixed according to the volume rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com