Darunavir amorphous form preparation method

A darunavir and amorphous technology, which is applied in the field of medicinal chemistry, can solve problems such as prolonging the production cycle, prolonging the distillation time, and easy puffing of materials, and achieves the effects of short production cycle, good solubility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

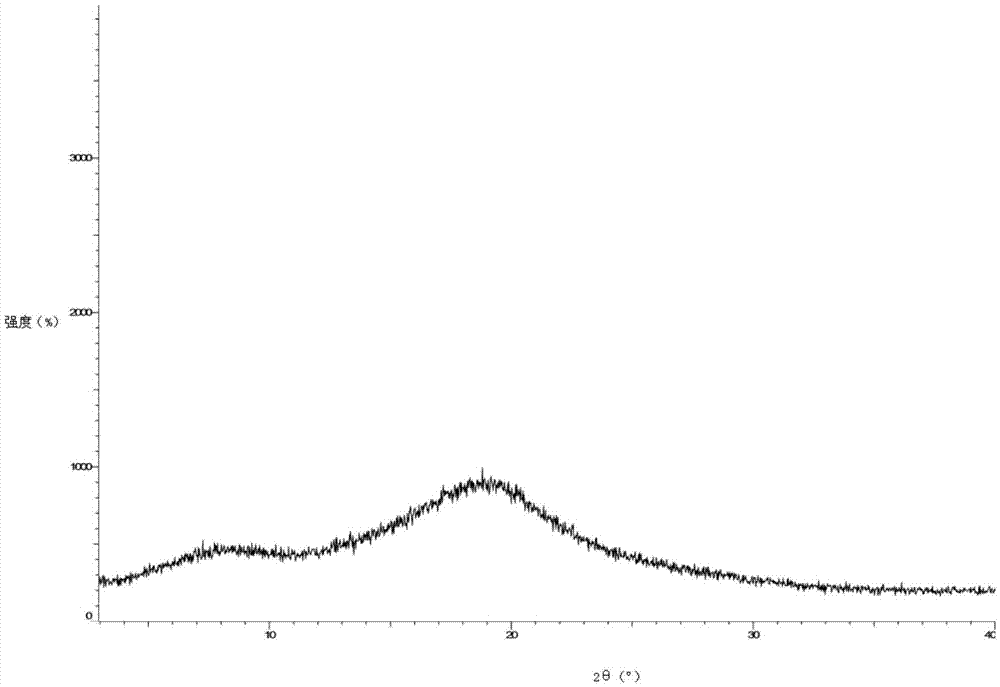

[0038] Add 50g of isopropyl acetate and 10g of darunavir into a 250ml four-necked bottle, stir, and raise the temperature to 50-60°C; Continue to keep warm for 1‐3 hours. Suction filtration, rinse with n-heptane. The wet product was dried in a vacuum oven at 60°C. 9.3 g of amorphous darunavir was obtained with a purity of 100.0% and a yield of 93.0%. Its XRPD as figure 1 shown.

Embodiment 2

[0040] Add 4g of acetone and 1g of darunavir into a 250ml four-necked bottle, stir, and raise the temperature to 50-60°C; -3 hours. Suction filtration, rinse with n-heptane. The wet product was dried in a vacuum oven at 60°C. Darunavir amorphous 0.95g was obtained with a purity of 99.9% and a yield of 95.0%. Its XRPD as figure 2 shown.

Embodiment 3

[0042] Add 50g of isopropyl acetate and 10g of darunavir into a 250ml four-necked bottle, stir, and raise the temperature to 50-60°C; after the solution is dissolved, add the solution dropwise to -10-0°C n-heptane, and filter with suction , n-heptane rinse. The wet product was dried in a vacuum oven at 60°C. 9.3 g of amorphous darunavir was obtained with a purity of 100.0% and a yield of 93.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com