Laminated ceramic electrical-heating element

A heating element and ceramic technology, applied in the field of layered ceramic heating elements, can solve the problems of power attenuation, high cost, high resistance wire temperature, etc., and achieve the effects of high thermal conductivity and electrical conductivity, good elastic properties, and excellent high-temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

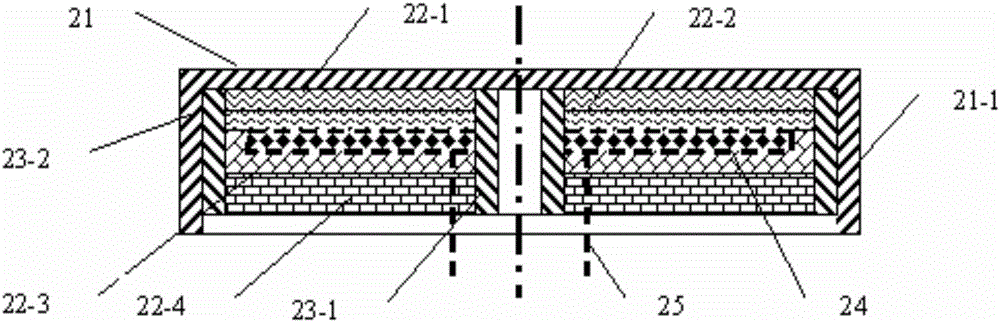

[0058] Embodiment 1, with reference to attached figure 1 .

[0059] What the present embodiment provides is disc-type laminar ceramic heater (nominal diameter 60mm, voltage 220 volts, power 600 watts), and it comprises austenitic·ferritic type (2205) duplex stainless steel plate 21, glass-ceramic substrate Multi-phase composite ceramics 22-1, 22-2, 22-3, 22-4 insulation layer, insulation layer with metal inner frame 23-1, metal outer frame 23-2, austenitic ferrite stainless steel plate 21 It has a flanging 21-1, and the flanging 21-1 constitutes the outer frame at the outermost periphery, and a cermet electric heating layer 24 is combined between the BAS-based glass-ceramic-based multi-phase composite ceramic insulating layer 22-2 and 22-3, The electrothermal layer 24 is combined with a nickel alloy electrode 25 .

[0060] The production process is briefly described as follows:

[0061] The electric heating layer resistance paste is composed of nickel-chromium-aluminum-yttr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com