Lithium sulfur battery membrane material and application thereof

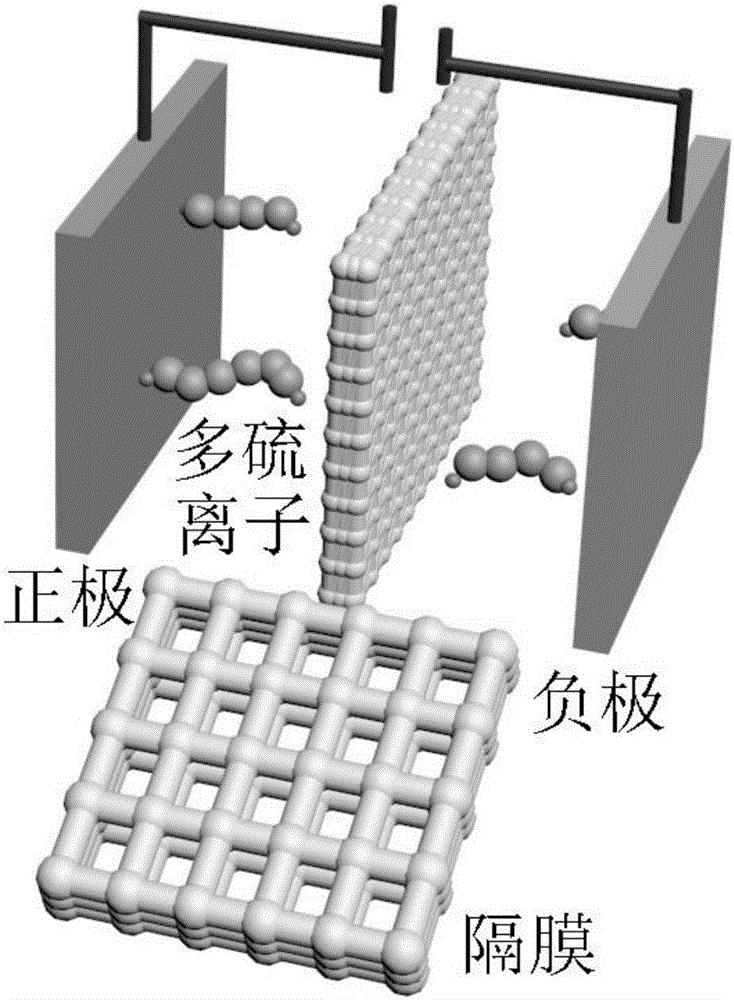

A lithium-sulfur battery and separator material technology, applied in the field of electrochemical batteries, can solve the problem that the diffusion of polysulfides in lithium-sulfur batteries cannot be well inhibited, the thickness, strength, and porosity are difficult to take into account, and the high temperature resistance and high current charge-discharge performance It has the advantages of alleviating lithium dendrite piercing ability, low cost of raw materials, and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of coating the sulfur cathode material on the current collector is the same as that in Comparative Example 1.

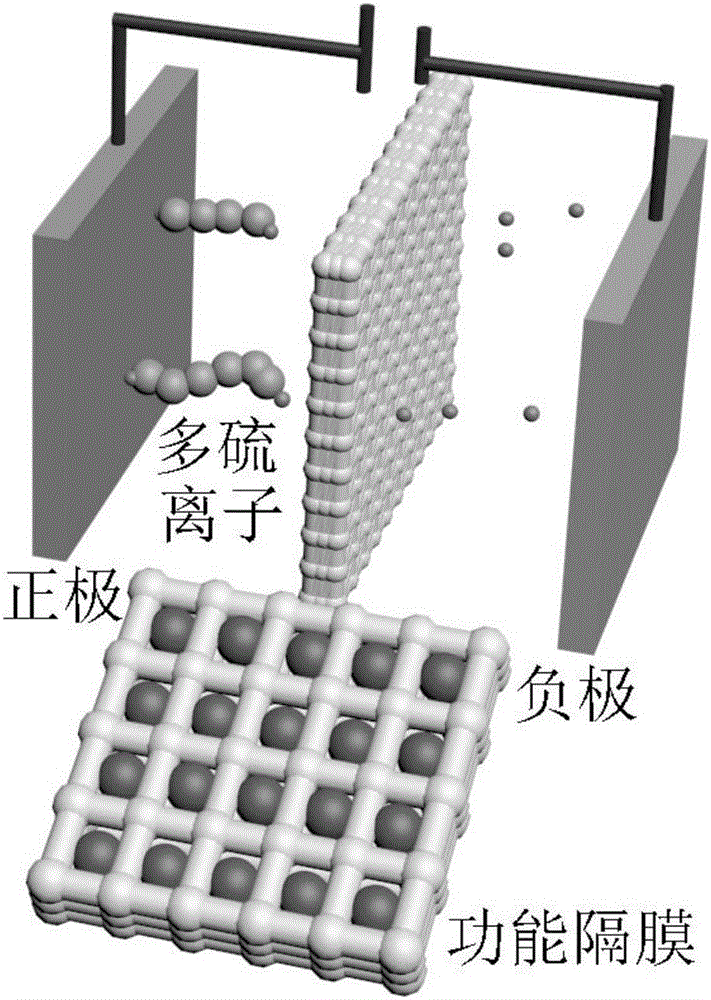

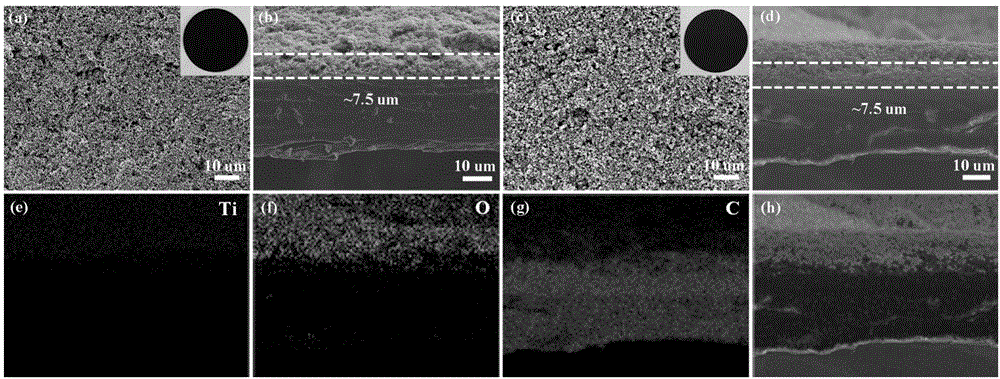

[0028] Metal lithium sheet is used as the negative electrode, Ketjen black and binder polyvinylidene fluoride (PVDF) are mixed at a mass ratio of 9:1, and N-methyl-2-pyrrolidone (NMP) is used as solvent, and then coated on poly propylene microporous membrane Celgard 2400, and then dried in a drying oven at 60 °C for 12 h to serve as a functional separator. Nanoscale Ketjen Black is uniformly loaded on a polypropylene microporous membrane Celgard 2400, such as image 3 a. The thickness of the functional membrane is 7.5 um, such as image 3 b. Use 1 mol L -1 LiTFSI and 0.2mol L -1 LiNO 3 / DOL+DME (dioxolane and ethylene glycol dimethyl ether, volume ratio 1:1) is a lithium-sulfur battery with a functional separator assembled as an electrolyte, such as figure 2 .

[0029] The functional separator coated with Ketjen Black can phys...

Embodiment 2

[0031] The preparation method of coating the sulfur cathode material on the current collector is the same as that in Comparative Example 1.

[0032] Metal lithium sheet is used as the negative electrode, nano-scale titanium dioxide, Ketjen black and binder polyvinylidene fluoride (PVDF) are mixed at a mass ratio of 7:2:1, and N-methyl-2-pyrrolidone (NMP) is used as the solvent, stirring After being evenly coated on polypropylene microporous membrane Celgard 2400, and then dried in a drying oven at 60 °C for 12 h, it was used as a functional separator. The nanoscale titanium dioxide composite material is uniformly supported on the polypropylene microporous membrane Celgard 2400, such as image 3 c. The thickness of the functional membrane is 7.5 um, such as image 3 d. Titanium, oxygen, and carbon are uniformly dispersed on the polypropylene microporous membrane Celgard 2400, such as image 3 e-h. Use 1 mol L -1 LiTFSI and 0.2 mol L -1 LiNO 3 / DOL+DME (dioxolane and et...

Embodiment 3

[0035] Mesoporous carbon / sulfur is used as the positive electrode active material, mixed with the conductive agent acetylene black, and the binder polyvinylidene fluoride (PVDF) at a mass ratio of 6:3:1, and N-methyl-2-pyrrolidone (NMP) is used as the The solvent was stirred evenly and coated on the aluminum foil of the current collector, and then dried in a vacuum oven at 60 °C for 12 h, as the positive electrode material.

[0036] Metal lithium sheet is used as the negative electrode, nano-scale titanium dioxide, Ketjen black and binder polyvinylidene fluoride (PVDF) are mixed in a mass ratio of 7:2:1, and N-methyl-2-pyrrolidone (NMP) is used as a solvent, stirring After being evenly coated on polypropylene microporous membrane Celgard 2400, and then dried in a drying oven at 60 °C for 12 h, it was used as a functional separator. Use 1 mol L -1 LiTFSI and 0.2 mol L -1 LiNO 3 / DOL+DME (dioxolane and ethylene glycol dimethyl ether, volume ratio 1:1) is a lithium-sulfur ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com