A kind of preparation method of modified diaphragm for lithium battery

A technology for lithium batteries and separators, which is applied in the field of preparation of modified separators for lithium batteries, can solve the problems that ion selectivity cannot be significantly improved, the thickness of polyolefin separators is increased, the performance of lithium batteries is affected, and the like, and the flying shuttle is suppressed. effect, improved wettability and fluid retention, excellent selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

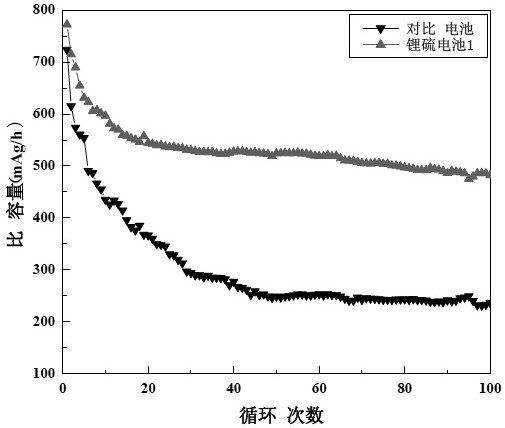

Embodiment 1

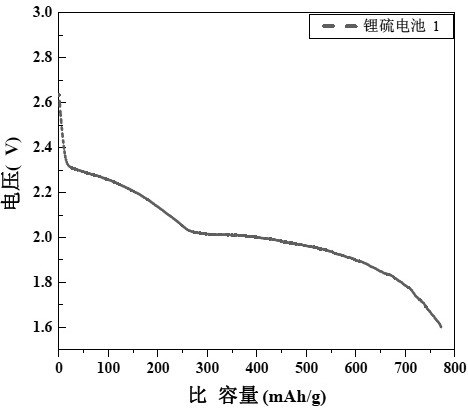

[0033] Positive electrode preparation process: The mass ratio of the slurry is mixed according to the mass ratio of sulfur: acetylene black: polytetrafluoroethylene = 90:5:5, and a 1×1 cm positive electrode is made on an aluminum sheet, and the prepared positive electrode is placed in a certain temperature for vacuum drying Dry at constant temperature in the box for more than 24 hours, and metal lithium is the negative electrode.

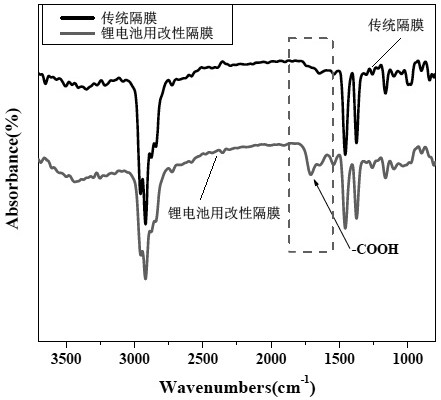

[0034] The preparation process of the modified diaphragm for lithium-sulfur batteries: the polyolefin diaphragm is ultrasonically cleaned for a certain period of time using acetone as the solvent, and then placed in a vacuum drying oven at a certain temperature to dry at a constant temperature for more than 24 hours, and the cleaned polyolefin diaphragm is single-sided Corona treatment (Corona Treating), the treatment time is 40 seconds, and the treated diaphragm is exposed to the air for 20 minutes.

[0035] Immerse the treated polyolefin separator...

Embodiment 2

[0037] The operation is the same as in Example 1, except that the cleaned polyolefin membrane is subjected to single-side plasma processing (Plasma Processing).

Embodiment 3

[0039] The operation was the same as in Example 1, except that the polyolefin separator was subjected to single-side corona treatment (Corona Treating), the treatment time was 80 seconds, and the treated separator was exposed to air for 20 minutes. A lithium-sulfur battery is assembled according to the positive electrode / separator / negative electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com