Perovskite CsPbBr3 thin film modified by zinc oxide nanoparticles and application of perovskite CsPbBr3 thin film

A zinc oxide nano, perovskite technology, applied in the structure of the active area, sustainable manufacturing/processing, final product manufacturing, etc., can solve the problem of low precursor concentration, poor film uniformity, and poor crystallinity of grains problem, to achieve the effect of fast carrier transfer rate, high density, and improved crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

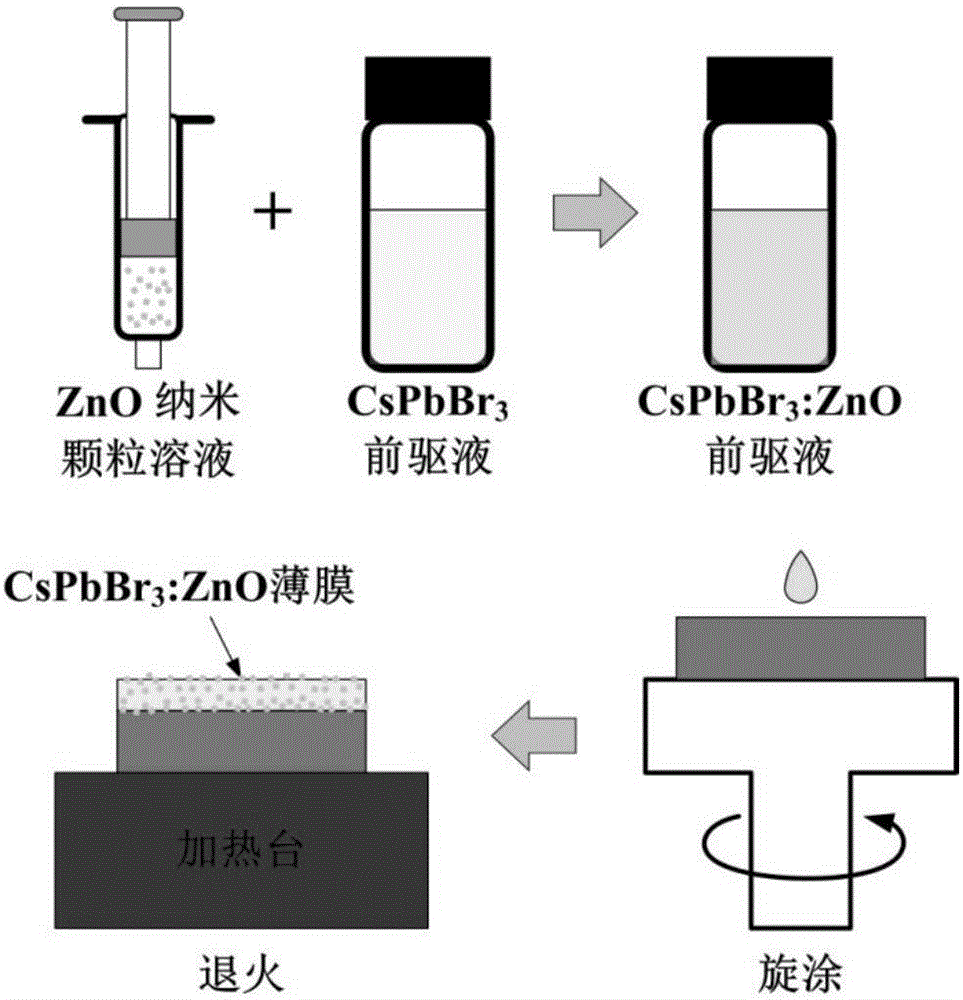

[0032]One-step preparation of ZnO nanoparticles-modified perovskite CsPbBr 3 film, the preparation process is as follows figure 1 shown

[0033] Mix CsBr powder, PbBr at a molar ratio of 1:1 2 Add the powder into dimethyl sulfoxide and mix well to prepare CsPbBr 3 precursor, and then to the CsPbBr 3 Zinc oxide nanoparticles were added to the precursor solution to a final concentration of 120 mg / mL to prepare CsPbBr containing zinc oxide nanoparticles 3 Precursor solution, and then CsPbBr containing ZnO nanoparticles 3 The precursor solution was spin-coated on the substrate and heated at 60 °C for 10 h to prepare ZnO nanoparticles-modified perovskite CsPbBr 3 film.

Embodiment 2

[0035] One-step preparation of ZnO nanoparticles-modified perovskite CsPbBr 3 film, the preparation process is as follows figure 1 shown

[0036] Mix CsBr powder, PbBr at a molar ratio of 1:1 2 Add the powder into dimethyl sulfoxide and mix well to prepare CsPbBr 3 precursor, and then to the CsPbBr 3 Zinc oxide nanoparticles were added to the precursor solution to a final concentration of 60 mg / mL to prepare CsPbBr containing zinc oxide nanoparticles 3 Precursor solution, and then CsPbBr containing ZnO nanoparticles 3 The precursor solution was spin-coated on the substrate and heated at 100 °C for 0.5 h to prepare ZnO nanoparticles-modified perovskite CsPbBr 3 film.

Embodiment 3

[0038] One-step preparation of ZnO nanoparticles-modified perovskite CsPbBr 3 film, the preparation process is as follows figure 1 shown

[0039] Mix CsBr powder, PbBr at a molar ratio of 1:1 2 Add the powder into dimethyl sulfoxide and mix well to prepare CsPbBr 3 precursor, and then to the CsPbBr 3 Zinc oxide nanoparticles were added to the precursor solution to a final concentration of 180 mg / mL to prepare CsPbBr containing zinc oxide nanoparticles 3 Precursor solution, and then CsPbBr containing ZnO nanoparticles 3 The precursor solution was spin-coated on the substrate and heated at 80 °C for 5 h to prepare ZnO nanoparticles-modified perovskite CsPbBr 3 film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com